A brake system or braking system in car or Automobile is explained along with various parts or components, types, working procedures, applications, advantages, disadvantages, etc. Let’s explore Brake System!

What is Brake System?

Let’s try to understand the basics of the brake system as well as the definition and function of the brake in car or automobile industries.

Brake System Basics

The brakes are an important part of the automobile vehicle. The brakes can be classified as a safety device. Brakes are advanced a lot since the start of the automobile revolution. For example, if you drive a car or any other vehicles with 100 km/hr speed and you required to stop the car, what will you do? Now, the brake comes into the picture! You will simply press the brake pad to stop the car! This brake pad helps to brake the car.

Let’s get into the definition of the braking system!

Brake System Definition

In general definition, a brake is a mechanical device that stops the motion progressively by absorbing the energy from a moving system.

The brakes are used to slow down, stop the vehicle is running.

- There are different types of brakes used in vehicles.

- They have different components and working as per their construction.

- But the primary objective of all the types is the same to stop the vehicle effectively without any problems.

- When the brake pedal is pressed the kinetic energy is converted to heat and then dissipated to the environment or it depends upon the different brakes.

Function of Braking System

Every vehicle is equipped with brakes. From your little bicycle to massive trucks and cars. Generally, on most vehicles, friction brakes are used. Even in some of the air-crafts to slow down the aircraft in the air brakes are used. We can summarize the main function of the braking system, as follow,

- Brake helps to stop the car or any vehicles.

- It protects vehicles from accidents.

- Brake helps to decelerate the speeding vehicles.

- To control the speed of vehicles.

- To avert the reverse movement in the slope.

- To park the vehicles.

We will see different types of brakes used in automobiles, their construction, types, and working.

Types of Brake System

Brake systems are classified into below categories,

- Mechanical brakes

These are frictional brakes, apply brakes by rubbing two surfaces on each other.

- Drum brakes

- Disc brakes

- Hydraulic brakes

These are the brakes operated on the hydraulic pressure. Hydraulic brakes are based on pascal’s law.

- Air/Pneumatic Brakes

- Electrical brakes

- Parking brakes

- Emergency brakes

So, all the above are the general types of brakes used in automobile vehicles. Now to know their working we will look into each brake type in details. Let’s see the brief description of all types of brakes.

Mechanical Drum Brakes

What is Mechanical Drum Brake?

The mechanical drum brakes are one of the oldest brakes available right now. They are not technologically advanced as compared to other brakes but are still used in some cars.

- In the year of 1990, Maybach presented a car with the drum brakes and later working was patented by Louis Renault.

- In the first version, Asbestos was used as a heat dissipation component.

- Later after the presentation of disc brakes by Jaguar the use of drum brakes was limited.

Let’s know some components of the drum brakes.

Components of Drum Brakes

Brake drum

The drum is made of cast iron material because of its heat resisting property.

- The drum has the primary objective to act as a middleman between the brake lining and the wheels.

- It rotates with the wheel.

- The brake drum is mounted on the wheel hub.

- As the brake drum rotates with the wheel, the drum needs to be stopped to stop the wheel.

Back plate

The back plate is like a protection or to provide rigidity to all the components inside.

- It is made of strong material to withstand the forces from roads like stones, debris.

- The backplate is mounted at the back of the system.

- It protects the whole assembly from getting damaged due to road forces.

Wheel cylinder

The wheel cylinder is available on almost every brake system.

- It controls the brakes shoes from which the brakes are applied.

- The wheel cylinder is located at top of the brake assembly.

Brake shoes

These are responsible for the vehicle to slow down or stop.

- They are controlled by a wheel cylinder; the friction lining is provided on the brake shoes.

- The brake shoes are available on the sides of the brake assembly.

Friction lining

The friction lining is available on the brake shoes.

- The friction lining is made of material with a high coefficient of friction and high heat resistance.

- It protects the brake shoes from wearing out quickly due to contact with the wheels.

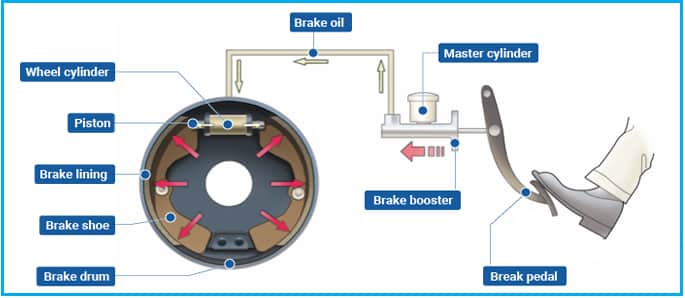

How Does a Drum brake Work?

Let’s see how does drum brake work pointwise,

- When the driver applies the brakes the hydraulic fluid immediately travels to the wheel cylinder.

- The wheel cylinder is equipped with two pistons and they start to push outwards when the hydraulic fluid is supplied.

- Due to this action, the brake shoes move outwards towards the brake drum.

- Now the brake shoes are equipped with friction lining, they rub against the brake drum.

- As the brake drum is mounted on the wheel and it rotates with the wheel.

- Stopping the brake drum will stop the wheel.

- The force from the brake shoes will slowly stop the brake drum and thus vehicle will slow down or stop.

Advantages of Drum Brakes

The advantages of drum brake, as follows

- Less number of working parts and easier to maintain.

- The prices of drum brakes are cheap compared to other brakes.

- Manufacturing cost is low and they are easy to mass-produce.

- Drum brakes can be used alongside disc brakes on different wheels.

Disadvantages of Drum Brakes

The disadvantages of drum brake, as follows

- Possibility of water, dirt and other things to enter inside the container.

- Heat dissipation is not easy due to enclosed design.

- Due to poor heat dissipation the wear and tear will be more.

- Not effective as other brakes

Disc Brakes

What is Disc Brake?

The drum uses the brake shoes whereas disc brakes use the callipers to slow down the vehicle. The disc brakes are quite famous and considered way more effective than the drum brakes.

- These brakes are available on every vehicle nowadays.

- The evolution of disc brakes started in the 1890s.

- Later Frederick Willian patented for use of calliper in the disc brakes.

- Jaguar launched three cars with a disc brake system and they won the race.

- This incident caused the disc brakes to get employed on other vehicles.

Components of Disc Brakes

Brake pads

The brake pads are mounted on the brake system. It acts like friction lining on the drum brakes.

- They are close to the rotor facing outwards.

- These are getting contacted with the wheels so these are made of durable material and high friction coefficient.

Rotor

The rotor is the same part as the brake drum in case of drum brakes.

- The rotors are attached directly to the wheel and it rotates with the wheel.

- It is the connection between the wheel and the brakes.

Caliper

The full assembly or you can call it as full housing is called as calliper. The callipers are mounted on the axles.

- Calipers do not come in contact with the rotor unless the brakes are applied.

- This will allow the wheels to move freely without any opposing force.

Pistons

The pistons are located inside the callipers. They are also known as “pot”. They are the connection to calliper and the brake fluid.

Master cylinder

The master cylinder is the one which force the fluid and control the operation. It has the tubes for flowing the hydraulic fluid towards the callipers.

Working of Disc Brakes

Let’s see how does disc brake work pointwise,

- The working of the disc brakes starts when the brake pedal is pressed.

- After pushing the brake pedal, it creates the pressure and this pressure is transferred to the master cylinder.

- The force received from pressing the pedal is converted to hydraulic energy by the master cylinder.

- Now the fluid reaches to pistons and pistons gets the push.

- Now because of the hydraulic energy from forced to pistons, the entire caliper assembly will move inwards.

- The inward movement causes to clamp down the rotor.

- Thus, the rotor starts to slow down and as the wheel is connected to the rotor wheel starts to slow down and stops.

Advantages of Disc Brakes

High stopping power

The disc brakes have high stopping power compared to the drum brakes. The disc brakes are able to stop high-speed car or slow down high-speed car more quickly and easily.

Easy heat dissipation

In case of drum brake, the design is an enclosed design. But in case of disc brakes the design is not enclosed and allows the constant air flow. Disc brakes will dissipate the heat easily and will not cause any heat problems.

No water retention

Unlike the drum brakes in which the water, dirt is retained. The water will flow right off because of easy design and there’s no stoppage of water. Also, this causes less wear and tear of the disc brakes.

Safer

The disc brakes are safer compared to the drum brakes. Even in hard braking, the wheels get locked up but in case of disc brakes wheels don’t get lock up.

Disadvantages of Disc Brakes

The advantages of disc brake, as follows

- Disc brakes are expensive as compared to the drum brakes.

- Disc brakes are more complex and advanced hence they cost more.

- We already know if there are complex parts the maintenance is obviously complex and tough. It will require more skilled person to repair the disc brakes.

- If the air enters the master cylinder or even in the tubes with hydraulic fluid. The brakes will fail instantly.

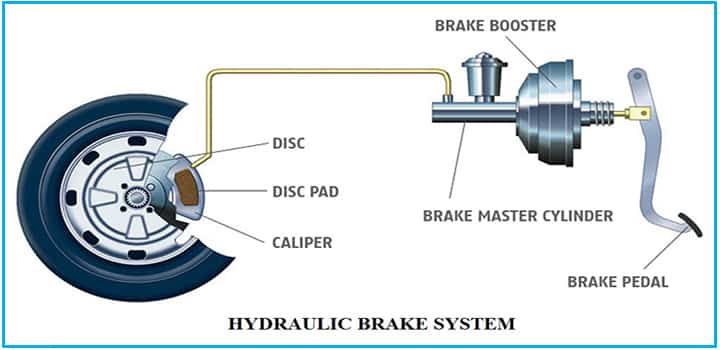

Hydraulic Brakes

What is a Hydraulic Brake?

The hydraulic braking system uses hydraulic fluid for the braking system.

- Hydraulic fluids like glycol ethers or diethylene glycol are used as the hydraulic fluid system.

- The hydraulic braking system works on the pascal’s principle.

- It states that the pressure change at any point in a confined incompressible fluid is transmitted throughout the fluid such that the same change occurs everywhere.

In 1904, Frederick George heath used a hydraulic water/glycerine brake system for a cycle. Malcolm Loughed invented the hydraulic brakes and patented the same in 1915.

Components of Hydraulic Brakes

There are various components in hydraulic braking system, let’s know them in a brief.

Brake pedal or lever

The pedal as we already know used to activate the brakes.

Brake master cylinder

It contains pistons assembly two pistons or return springs. This is an important unit of every braking system that converts the applied force from the pedal to hydraulic force. The master cylinder’s purpose is to develop pressure, equalize pressure.

Wheel cylinders

The wheel cylinders are used to convert the hydraulic pressure received from the master cylinder to mechanical pressure. Because of the mechanical pressure, brake shoes are pushed.

Brake lines and hoses

The lines and hoses are used to transfer the hydraulic fluid. The brake lines are rigid and brake hoses are flexible. On the wheels the brakes are used are drum or disc brakes. But as we discussed earlier the disc brakes are much more superior than drum brakes, this the use of disc brakes on all wheels is getting popular.

Working of Hydraulic Brakes

Let’s see how does hydraulic brake work pointwise,

- The work starts after pushing the brake pedal.

- The pressure is created and the push rod exerts the force in the master cylinder.

- Due to pressure fluid from the master cylinder will start to flow into the pressure chamber.

- The fluid is passed through the compensating port. It causes the entire pressure hydraulic system to rise.

- The force is applied through the calipers.

- The pistons in the calipers are sealed with an o-ring to prevent the leakage of hydraulic fluid.

- Now the brake caliper will apply the force on the brake pads

.

. - It will push the brake pads against the spinning rotor and the friction between pads and rotors will cause the wheels to slow down or stop.

- When the entire hydraulic system pressure rises from that point the working depends upon the type of brake used.

Disc and drum-type brakes can be used or a combination of two on different wheels.

Advantages of Hydraulic Brakes

The advantages of hydraulic brake, as follows

- Better heat dissipation compared to mechanical brakes.

- Less wear and tear hence they are durable and have long life.

- Hydraulic brakes are safe and effective than mechanical brakes.

- Braking effort is applied to all wheels equally.

- Force multiplication is possible easily by just changing the piston and cylinder relative to each other.

Disadvantages of Hydraulic Brakes

The disadvantages of hydraulic brake, as follows

- Costlier than the mechanical brakes.

- Brake failure chances if the fluid leaked.

- Construction and maintenance of hydraulic brakes is not simple as mechanical brakes.

- Fluid should be well working with the brake material.

- Fluid leakage can ruin the brake shoes.

Air Brakes

The air brakes are also known as the compressed air brake system uses compressed air as a working medium. Just like in the hydraulic system the hydraulic fluid is used in air brakes the compressed air is used. These are generally used in large and heavy vehicles. George Westinghouse used air brakes in railway service and later patented safer air brakes on 5 March 1872. Let’s know the components of the air brakes.

Components of Air Brakes

Air compressor

The air compressor is used to pump the required air. The are gear driven or belt driven from the engine. The compressors use the vehicle’s own lubrication system and cooling system or they are self-lubricated and self-cooled.

Reservoirs

The reservoirs store the compressed air. It holds the pressurized air until it is required for the braking operation. The air pressure for brake applications is decided according to the compressed air available in the reservoirs.

Foot valve

You can call it as a brake pedal. You will need to apply the foot valve to apply the air brakes.

Brake chambers

The brake chambers are the same like wheel cylinder in the hydraulic brakes. The brake chamber will convert the compressed air pressure to mechanical pressure to apply the brakes.

Working of Air Brakes

Let’s see how does air brake work in pointwise,

- When the driver steps on the foot valve, air from the atmosphere enter the compressor.

- The air is filtered by an air filter before getting into the compressor.

- From the compressor, it reaches the reservoir where the air is stored.

- Due to the force applied the air from the reservoir will pass to brake chambers.

- Now the compressed air energy will be converted into mechanical energy.

The later working of the air brakes depends upon brakes used like a drum or disc brakes.

Advantages of Air Brakes

The advantages of air brake, as follows

- The air brakes operate on the air, the supply of air is unlimited so the air brake system will never run out its operating fluid.

- Even considerable leakage happens the air brake are effective.

- Air brakes can be designed with “fail-safe” ability it will stop the vehicle even the with the leakage.

- Other applications like air horn or seat adjusters can be used.

- Even if the compressor fails air tank can store sufficient energy to stop the vehicle.

Disadvantages of Air Brakes

The disadvantages of air brake, as follows

- Costs more than hydraulic braking systems.

- When the air is compressed it needs dryers to remove the moisture.

- Because of more parts the air brakes costing increases with high maintenance as well as repair costs.

- Not easy to learn as other braking systems, because air brakes are difficult to operate smoothly.

- Requires more knowledge and skills while operating vehicles with air brakes.

Electrical Brake System

The electrical braking system is used in modern electric vehicles. The braking is achieved with the help of 3 motors. The types of braking are divided into three types.

Regenerative braking

Regenerative braking is an energy recovery mechanism that slows down a moving vehicle or object by converting its kinetic energy into a form that can be either used immediately or stored until needed.

- The regenerative braking system is popular nowadays and used in cars like Tesla Model-S.

- It stores the energy in the battery after wheels becoming the rotating force for the motor.

Plugging brakes

When the driver pressed the brake pedal, the motor polarity will change and thus brakes will be applied.

Dynamic or Rheostat Braking

In this braking system the resistance is provided with the help of rheostat. Rheostat provides the resistance to the motor which cases slowdown of the vehicle.

Electromagnetic Braking System

The electromagnetic braking system is the new style of braking system which is getting popular nowadays. use of the electric motor to get the vehicle come to a stop.

- It is also used in hybrid vehicles.

- Electromagnetic braking uses the electric motor to get the vehicle come to stop.

- It is also used in hybrid vehicles.

- In the working of this system, a magnetic flux is passed with the direction perpendicular to the rotating direction of the wheel.

Now the rapid current will flow with the opposite direction of rotation of the wheel. Thus, the opposing force will be created and it will slow the wheel.

Advantages of Electromagnetic Brake

The advantages of electromagnetic brake, as follows

- Electromagnetic brakes are fast applying type and cheap.

- High heat dissipation capacity.

- Electromagnetic brakes have better thermal performance compared to other friction brakes.

- No oil leakage problems.

- Reduced maintenance costs.

- There is problem in fluid brake system of fluid vaporization, it is eliminated in electromagnetic brakes.

Disadvantages of Electromagnetic Brake

The disadvantages of electromagnetic brake, as follows

- The dependence on the battery can drain battery much more.

- Residual magnetism as they are present in the electromagnets, takes time for shoe brakes to come on original position.

- Need of electric power.

- Less effective under low velocities

Parking Brakes/ Hand Brakes

These brakes are independently operated. The normal brakes are operated by the use of foot pedal, the parking brake will activate with small pedal under steering systems.

- The parking brakes are mechanical type brakes.

- Usually, the handbrake is equipped for the rear wheels.

- If the hydraulic braking fails it can give some limited braking for the vehicle.

Emergency Brakes

As the name suggests these are used when the primary braking system fails. They can be also called secondary brakes. They work independently of the normal braking system.

- They are divided as stick level, center lever, pedal, electric push or button.

- The emergency brakes are like the safety brakes available in vehicles.

- If somehow primary brakes fail to operate or fails to stop the vehicle the emergency brakes can be used to stop the vehicle properly.

New Technology in Brake System

So, all these are the types of brakes used in automobile vehicles. Some new advancements are getting added in the brakes like the anti-lock braking system. The sensors are getting used more specially on modern luxury cars to get most out the brakes. Like using sensors to detect the obstacles and apply the brakes. These are most popular on electric vehicles which are considered to be the future of the automobile industry.

Manufacturers of Brake

There are many manufacturers available for the braking system, few of them are listed,

- Brembo

- Beringer SAS

- EBC Brakes

- Continental

- Stop-Tech

Conclusion

Hence, we have got a basic idea about braking system, along with definition, meaning, types, working principle etc. Any comments! Feel free to ask.

Our Videos

Refer YouTube