Carburetors, the heart of automobiles, are described along with its definition, parts, diagrams, and how carburetor works along with its various types. We all know vehicles need to run on combustion principles. It needs fuel gasoline to be mixed with correct proportions of air to cause combustion. This combustion helps to generate the power to move the vehicle.

What are Carburetors? Definition, Function

So how the air-fuel mixture is managed? Here comes the carburetor’s role for managing the air-fuel mixtures for the correct quantity. Though these are not found in modern cars but they were used in almost every vehicle type from commercial to racing. The main goal of the carburetor is to mix just the right amount of air-fuel mixture to get the desired and optimum combustion possible.

Carburetors Definition: Define Carburetor

We all know that in the case of gasoline or petrol engine, fuel is used and with the help of spark ignition along with air, combustion happens in the combustion chamber. The component which is used to mix the fuel with air for combustion is defined as a carburetor.

- It is applicable only in internal combustion engine.

- It is applicable only in petrol engine or where spark ignition is applied.

Simply, the carburetor supplies fuel for the combustion. It mixes with the air and fuel mixtures at the correct quantity needed for optimum combustion processes.

Stoichiometric Ratio

The optimum air-fuel mixtures are known as stoichiometric ratios. It’s the ideal ratio of air-fuel mixture which is 14.7:1. It denotes for every 1 gram of fuel you need about 14.7 grams of air for ideal combustion. That’s where the role of carburetors role kicks in.

Carburetors History

The invention of carburetors was going through a very big cycle, let us glance in brief,

- If we look towards history, the first carburetor was invented by Samuel Morey in 1826.

- Later in 1872, Siegfried Marcus filed a patent to use carburetor in petroleum engines. That was later developed by Carl Benz.

- The use of carburetor was more popular in 1980s vehicles in the USA. Cars like Subaru Justy, Mazda B2200, Jeep Wagoneer were all based on Carburetor in those times. But they were phased out mostly after the 1990s due to the introduction of an efficient fuel injection system.

- But these were still used in stock car racing events like NASCAR in 2011.

Let’s know more about the functions and the parts of the carburetor.

Functions of Carburetors: What is the function of a carburetor?

- The main or prime function of a carburetor is to supply the air-fuel mixture in an optimum ratio to get the highest combustion efficiency.

- Regulation of air-fuel mixture ratio.

- Varies amount of mixture according to the engine speed and load changes.

- Supply the correct amount of air-fuel mixture at various loads and speeds.

- It helps to control the engine speed by regulating the air-fuel mixture.

- It helps to properly burn the fuel.

Parts of Carburetors: Parts in a Carburetor with Names

So, what are the parts of the simple carburetors? Let’s try to understand. There are various parts in a carburetor. It has the following,

- Carburetor Venturi

- Throttle Valve

- Strainer

- Idle System

- Off idle or part idle circuit

- Open throttle circuit

- The metering system

- Float chamber and mixing chamber

- Accelerator Pump

- Carburetor Choke Valve

Diagrams of Carburetor: Explain Diagram of Carburetors

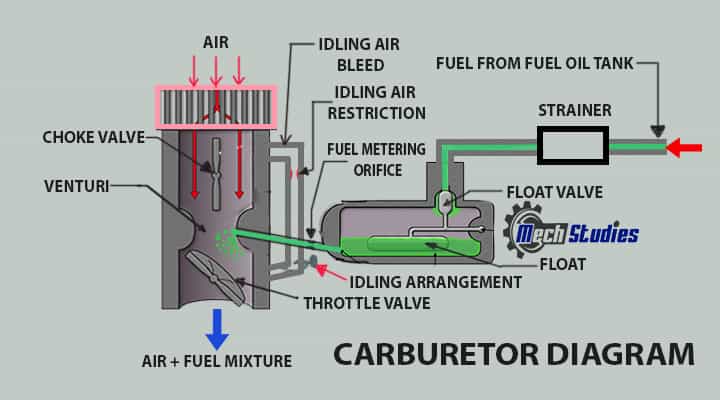

Let’s try to understand the diagram of the carburetor in the simplest way. The purpose of a carburetor is to mix fuel with air when the air-fuel ratio for combustion is appropriate for internal combustion engines. If the carburetor is not functioning properly, the engine won’t work right, give the right horsepower, or run smoothly. See a typical carburetor diagram:

Diagram of a Carburetor

A simple carburetor diagram is indicated below, so have a basic idea before the description of carburetor parts.

Carburetor Diagrams Explanation

The working mechanism of a Carburetor is explained in the above-illustrated diagram. In most vehicles that travel on land, water, or in the air, power is generated when fuel and air combine to create power which is then burned in metal cylinders inside engines.

Carburetors contain two rotating valves located above and below the venturi. Located at the top of the carburetor, the choke is responsible for controlling and regulating the airflow. Putting the valve closed will reduce the amount of air entering the venturi, which in turn will suck in more fuel, making the engine run more efficiently. If the engine has just been started or if the car is cold and needs time to warm up, which is especially helpful.

The valve that throttles on a carburetor is present in the second valve. A green throttle opens and closes the pipe by swiveling it. Increasing the throttle increases the amount of air and fuel flowing into the cylinders, resulting in more power and a faster car when the throttle is open.

This mini-fuel tank is known as a float-feed chamber and provides orange fuel. With the fall of the fuel level, a float in the chamber falls, resulting in the opening of the top valve. Fuel is pumped from the main gas tank into the chamber when the valve opens. As a result, the float rises, and the valve close again.

By widening the throttle, more air passes through the carburetor, allowing it to drag more fuel from the pipe to the sides, allowing the engine to release more power, allowing the car to go faster.

It is very low pressure produced by the induction manifold when an engine is idling. In order to prevent stalling, a different mechanical process takes place. Fuel jets keep a minimum amount of fuel flowing through small metal tubes. The primary process begins once the throttle valve opens, disengaging these jets. There is a separate section on how does carburetor works in this article to have a clear understanding of the working process,

Carburetors Parts Description

Let’s check the components one by one.

Carburetor Venturi

What is Carburetor Venturi? We have already learned venturi meter, and here, carburetor venturi also works based on the same philosophy. It is basically a passage that has a gradual decrease in its cross-section area.

Function & Working Process: This venturi is narrow in the middle and air is passed through this narrow tube. Airflow is the same within this tube and air velocity is varied based on the cross-sectional area. Air velocity is maximum in the narrowest section. It reduces pressure and creates slightly low pressure.

Based on the variation of the cross-sectional area, air quantity is adjusted in the mixture. Based on the shape or function, carburetor venture can be many types,

- Plain or Single Carburetor Venturi

- Double Carburetor Venturi

- Triple Carburetor Venturi

- Vane Carburetor Venturi

- Nozzle Bar Carburetor Venturi

- Variable Carburetor Venturi

Throttle Valve

What is Throttle Valve in Carburetor? The throttle valve is a major part of the carburation system. We have already learned that there is carburetor venturi is to adjust the airflow. Below the venturi, there is a butterfly valve known as the throttle valve.

Function: It just acts as our home water tap. Just like the water tap the flow can be controlled as fully open or close same happens in case of the throttle valve. It controls the air which can be passed to mix with the fuel.

Control: The throttle valve link is connected to the accelerator of the vehicle.

- When the driver increases the speed through accelerator, the air will be taken more and vice versa.

- On the other side the fuel is taken into the air stream through small holes at narrow part of the venturi.

- Whereas at other places pressure is lowered when not running at full throttle.

Strainer

Description: The strainer is filtering equipment used to filter the fuel.

Function: The function of the strainer is to filtrate. Here, it filters the fuel before entering the float chamber.

How Does Strainer Works in Carburetors? It has a wire mesh structure that is responsible for removing dust and suspended particles. If these particles are not removed it can serious blockage issues and the vehicle will not start.

Idle System

When the engine is going to be in idle condition, the throttle valve will be almost closed. Airflow through will not be able to create enough vacuum in the carburetor venturi which will not be able to pull the fuel. In this case, the idle system comes into the picture. This system or circuit helps to feed fuel into the air. Normally, at below 800 rpm, the carburetor idle system provides the air-fuel mixture. It consists,

- Main discharge tube,

- Idle passage

- Bypass

- Low- speed jet,

- Idle air bleed,

- Economizer,

- Idle screw port, &

- Idle mixture screw.

Off Idle System

What is the Off Idle system in Carburetor? Off idle or sometimes called part throttle is the main part used to feed more fuel. When the throttle valve is slightly open from the closed position, fuel delivery holes are uncovered. The idle system alone is not able to meet the fuel requirements in the air stream of the carburetor. When the engine changes from idle condition to high speed, the off idle system is able to supply the fuel.

Function: The low-pressure area is created by the throttle valve which blocks the airflow. Thus, allowing more fuel to enter to compensate for reduced vacuum pressure and to smooth the operation to a regular open circuit.

- It is an idle system extension.

- It works above 800 rpm.

- If off idle system is not present, fuel mixture will be lean mixture.

The idle system will not be able to supply a sufficient amount of fuel alone, and an off idle system is required. It supplies fuel when the vehicle changes its idle condition to high speed.

Operation: The operation of the Off idle system, as follows:

- The driver of the vehicle presses down the accelerator.

- The throttle plate will be slightly opened.

- Off idle ports will be exposed towards the manifold vacuum of the intake.

- This vacuum pulls the fuel out of the idle screw & the off idle port.

- Provides sufficient extra fuel to mix with the additional air.

Open throttle circuit

What is Open throttle circuit in carburetor? When the throttle valve is getting slightly opened the manifold vacuum gets weakened because of less restriction to airflow. This results in reducing the fuel flow through off-idle circuits. Now the role of Venturi components kicks in.

Explanation: We know Bernoulli’s principle, where the velocity increases pressure will fall.

- The venturi increases the velocity of air causing the causing a drop in pressure fuel. Hence, the fuel gets sucked through the nozzles located in the center of the venturi.

- Whereas, when the throttle valve is closed again airflow will drop to the pressure where the pressure is not capable to maintain the flow.

The metering system

As the name suggests it controls the flow of fuel into the nozzle. It is responsible to get the correct mixture of air and fuel. It has two parts,

- Metering orifice and

- Fuel discharge nozzle.

As we have already seen low pressure is generated when the air passes through the venturi. Due to this fuel gets discharged into the air stream. The main function of the metering system shall be as follows,

- Maintaining air-fuel proportion in the mixture.

- Reduction of pressure at the discharge nozzle.

- It controls the rate of air flow at full throttle

Hence, the quantity of fuel is controlled by the metering orifice and discharge hole at the exit of the nozzle.

Float chamber and mixing chamber

Description: This is for the storage of the fuel so as to maintain the continuous supply of the fuel.

- If the fuel gets less than the required amount, then the float will move downward causing the fuel supply valve to open and admit the fuel.

- Similarly, when fuel supply is more float goes upward restricting the fuel admission.

Function: This is where the actual mixing air and fuel is obtained. The mixture of air + fuel is created in this chamber and then supplied to the engine cylinder. To avoid the heating of the fuel in the float chamber in hot climates heat deflectors and insulating gaskets are used. It reduces the “heat soak” effect.

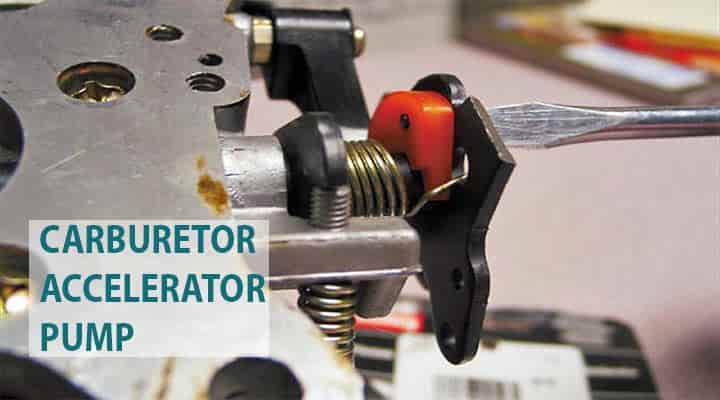

Accelerator Pump

Description: Gasoline is denser than air, so obviously, air will react more and travel more quickly compared to Gasoline. When the driver accelerates suddenly the throttle valve opens up and immediately tries to admit the mixture even more.

But the air pressure inside the manifold increases which decreases the evaporation of the fuel, this results in less fuel gets entered into the engine. When the quantity of air is more the mixture is called a lean mixture. When the too lean mixture is transferred to the engine, the engine causes misfiring.

Function: All these problems are corrected by the use Accelerator pump.

- It forces the small amount of gasoline quantity through a jet into carburetor’s throat.

- So this extra fuel will counter the lean mixture conditions and will adjust the mixture suitable for combustion.

Choke Valve

Description: The choke valve is most useful in cold climatic conditions. In cold conditions, the fuel is present in less quantity in the cylinders and makes difficult to start the engine. So to counter this situation more rich mixture needs to be provided. In short, more fuel should be supplied compared to the air to start the engine. So the choke controls the flow of air at the entrance of the carburetor.

is most useful in cold climatic conditions. In cold conditions, the fuel is present in less quantity in the cylinders and makes difficult to start the engine. So to counter this situation more rich mixture needs to be provided. In short, more fuel should be supplied compared to the air to start the engine. So the choke controls the flow of air at the entrance of the carburetor.

Understanding: You may have tried opening up the choke valve mostly on two-wheeler bikes.

- The choke restricts the air flow which results in more admission of fuel compared to air.

- In case of cars, there was manual chokes available but later automatic chokes were employed. But there is one thing to note that, we should deactivate the choke once the engine started.

- If the choke is not deactivated it will cause more fuel admission, increasing emissions.

- The fuel will be wasted and vehicle may get other problems.

Parts of Modern Carburetors

Since there are many disadvantages of the simple carburetor, it is modernized and added a few additional modern components, like

- Automatic mixture control

- Throttle return check

- Anti-dieseling solenoid

Automatic Mixture Control

Automatic mixture control means a plunger-shaped valve, which is operated by a solenoid and Spring.

- Automatic mixture control system controls the separate jet in the float chamber.

- Valve is open when the solenoid is turned on. It increases the fuel supply to the jet.

- The solenoid is operated by the signals from engine speed etc., and everything is measured by an electronic device.

- If the solenoid is turned off, the spring helps to close the valve to decrease the fuel supply.

Throttle Return Check

When the throttle valve is open completely, the engine will run at a very high speed. It may create a high intake manifold vacuum.

- This vacuum may have a probability to draw exhaust into the engine intake.

- This exhaust will dilute the intake proportions.

- Misfiring or even stall may happen.

Now, to avert this problem, the throttle return check valve is connected in modern Carburetors with the help of linkages.

Anti-dieseling Solenoid

Now a day, vehicles are used various modern emission control engines. These engines are normally working at high temperatures.

- Due to this high temperature, there may be a chance of producing hot spots in the combustion chamber.

- Hot spots can create pre-ignition in the combustion chamber.

To avert this pre-ignition, a modern carburetor is provided with an anti-dieseling solenoid and turns off the pre-ignition. Now we have seen all the parts present in the basic carburetor structure. There are some additions to the newest carburetors like throttle return check, anti-dieseling solenoid, and automatic mixture controls. Now let’s see how the Carburetor works.

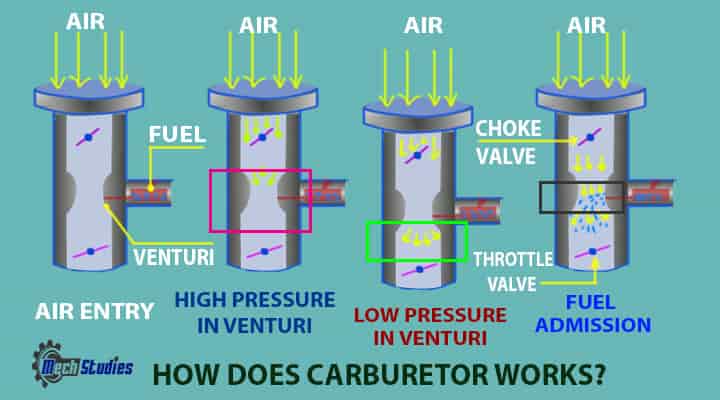

How does Carburetor Works? Explained with Diagrams

The structure of the carburetor may seem a bit complex but the working is pretty much easy to understand.

Let’s know the working pointwise to understand it easily.

- The air flows down the pipe and it passes through the narrow venturi as we discussed in the above sections. Due to a decrease in the pressure, the sucking effect is created.

- This sucking effect causes the fuel admission and the air-fuel gets joined for further process.

- At the start of the vehicle, the choke can be turned on so as to start the engine in cold regions in rich mixtures.

- The driver accelerates the link is connected to the throttle valve. The more throttle gets opened the more air will be admitted and similarly the fuel.

- As the accelerator is turned more, a large quantity of air fuel mixture is admitted, hence the engine generates more power and the vehicle speeds up.

- The fuel chamber supplies the fuel. When the fuel goes down float will move down causing more fuel to admit. If the fuel is more the float will close the valve restricting the admission of fuel.

This cycle runs continuously till the vehicle is switched on. There are various types of carburetors used let’s know more about them they are very easy to understand.

Types of Carburetors with Diagrams

There are three types of carburetors namely,

- Updraft type carburetor

- Horizontal type carburetor

- Down-draft type carburetors.

These types are differentiated on the basis of air intake.

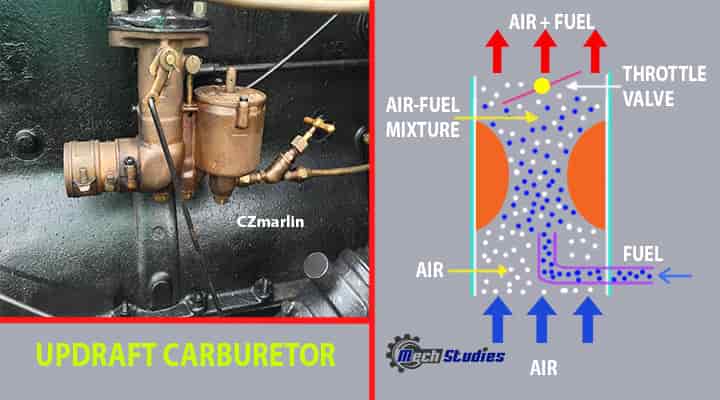

Updraft Carburetors

- The updraft carburetors are those in which the air is supplied from the bottom of the mixing chamber.

- This one is placed lower side of the engine and uses gravity fed-fuel supply. In simple words, the tank is placed above the carburetor and fuel falls into it.

- The air-fuel mixture is forced upward.

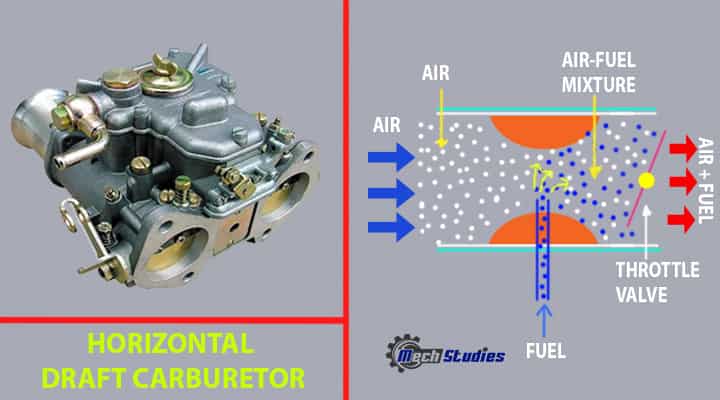

Horizontal Carburetors

- The horizontal carburetors get the air from one side of the carburettor. Hence it is known as horizontal carburetors.

- Basically, if you rotate the downward draft carburetor it will be known as the horizontal carburetor.

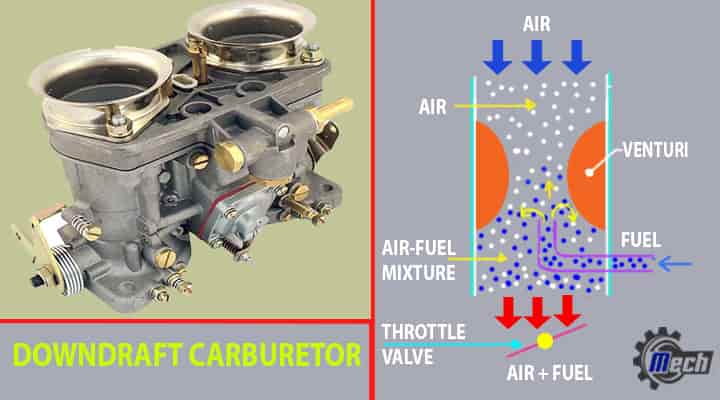

Downdraft Carburetors

- Similarly, the downdraft carburetors are the one which supplies the air from the above portion of mixing chamber. Among the 3 types, downdraft carburetors are used mostly because of some advantages.

- The gravity assists the air-fuel mixture engine will pull better at lower speeds. Because of this, the engine with downdraft carburetors can achieve higher volumetric efficiency.

- The only disadvantage it has the jet overflow because of the possibility of leakage directly into the inlet manifold if the float is defective.

The use of carburetors was stopped due to introduction of the fuel injection technology. There are some advantages and disadvantages of the carburetor let’s know them now.

How to Clean a Carburetor?

A car’s Carburetor must be cleaned from certain time to time in order for the carburetor and the car to function properly as a whole. In an engine, the carburetor is the most vital component. This results in the carburetors and chokes valves becoming clogged with dirt, varnish, gum, etc., affecting the engine’s performance. To maintain engine health and boost performance, it is necessary to clean the carburetor regularly.

Before you attempt to try and clean the carburetor you must always check the car’s manual and follow the complete instructions given for cleaning and the maintenance of the car. Then follow the steps and use the following materials to clean your car’s carburetor.

Dilute the cleaning mixture

First, take a large container and the dilute the cleaning mixture with water. The problem is that the plastic or rubber pieces on the carburetor have to be cleaned with a cleaner that does not harm or degrade them. Rust can happen to metal when it comes into contact with vinegar’s acetic acid. Moreover, chlorine is corroded by metals such as steel and aluminium, and rubberized seals are degraded by bleach.

Clean the air filter

Ensure that the air coming into the carburetor is clean and free of blockages, which can lead to black smoke emissions from the exhaust before cleaning your carburetor. The fuel supply should be turned off, and if a spark plug connection exists, the spark plug wire should be disconnected. Ensure the housing and the wing nut that attaches the filter are removed, as well as the outer element. Compressed air can be used to remove debris from the air source.

Take out the carburetor

Use pliers and a screwdriver to remove the covering plate, shield, linkage, and hoses. A hose clamp connecting the carburetor to the fuel line should be removed as well as any covers and clamps holding the carburetor in place so you have to firstly remove the covers and the clamps.

Use compressed air to blow off the exterior casing of the carburetor after removing it. This process is a little complicated so if you are not familiar with the parts you must consult a professional mechanic before continuing with the process.

Detach the carburetor float

Be careful not to spill any remaining gas inside the float and dispose of it securely. Remove the bolt that holds the carburetor float which looks like a bowl-shaped container in place. The varnish buildup on this area of a carburetor is a common problem. In addition, remove the pin on which the float pivots and place it aside in a safe place. Remove the float from its casing straight away.

All removable contents are then to be removed

Make sure you note where any other carburetors components are being removed so that you can clean them.

Soak and scrub all the parts

To thoroughly clean the carburetor float and other components, immerse them in your dilute cleaner mixture for 10 minutes. Metal components should be scrubbing with a brass brush, while plastic components should be scrubbed with a stiff nylon brush. Do not forget to clean the tiny vents. In addition to cleaning the small parts, use the cleaning solution to clean them.

Wash out and dry

Allow all carburetors components to air dry completely after gently and properly washing them in a bucket of clean water. Compressed air can be used to remove any excess moisture from small holes and vents.

Replace and Reassemble

Ensure that the carburetors are properly reassembled and that they are mounted to the engine. Make sure all cables, hoses, and clamps are re-connected properly as they were from the beginning.

Carburetor Adjustment Tool

A carburetor adjustment tool is a type of special-looking screwdriver that is used on An engine’s carburetor adjustment tool controls how much air and fuel are mixed together in an engine carburetor using a special-looking screwdriver. An engine’s idle speed and smoothness can be adjusted by adjusting a screw that is present by using this particular type of screwdriver.

Carburetor Rebuilding

As ethanol is added to today’s fuel, the gasket, seal, and float tend to deteriorate, so eventually you will have to rebuild your carburetor. Basically, a carburetor kit, a few basic tools, and a cleaner are all you need to rebuild a carburetor. Before fuel injection was introduced to performance vehicles, carb rebuilding was a routine procedure in garages and backyards.

Advantages of Carburetors

The advantages of carburetors are as follows,

- The carburetors parts are not that much of expensive as compared with fuel injectors.

- The more air-fuel mixture can be acquired using carburetors.

- If considered a road test, carburetors have more power and precision.

- They are not restricted to the amount of gas pumped by the fuel tank. Cylinders can pull more fuel from carburetors achieving higher power.

- Allows users to tune up carburetors according to requirements.

- They can be serviced separately without touching the engine.

Disadvantages of Carburetors

There are disadvantages of carburetors as well, these are,

- At low speeds, the carburetor is not capable to provide the proper mixture.

- The changes in the atmospheric conditions affect the working efficiency of the carburetor.

- More fuel consumption compared to fuel injectors.

- Components like the diaphragm of carburetors are delicate and easily get damaged.

- Engine smoothness is affected due to air-fuel mixture fluctuation.

There are various disadvantages compared to fuel injection. Carburetors are now becoming obsolete as even the small bikes are incorporating fuel injection technology because of advantages and advancements in fuel injection technology.

Manufacturers of Carburetors

There are a lot of carburetors manufacturers across the globe, few of them are listed below,

- AMAL,

- Carter,

- Dell’Orto

- Hitachi,

- Holley,

- Keihin,

- Solex

- SU Carburettors,

- Weber carburetor,

- Zenith,

- Fretlog India

- Nikki India Fuel Systems

- Pacco Industries Corp.

- Noble Industries. India.

- Craftsman Automation Pvt., Ltd.

- Apa Engineering

Frequently Asked Questions for Carburetors

What does a Carburetor do?

Alternatively spelt carburetor, a carburetor is a device used to mix fuel and air for ignition in an engine. Fuel is stored in a storage chamber within a carburetor, which also contains a choke, a slow-working jet, the main jet, and venturi-shaped restrictions on air flow.

A carburetor combines fuel with air to make a mixture that’s ideal for combustion. A modern car’s fuel-injection system limits fuel consumption and pollution because it feeds the cylinders more efficiently.

The carburetor manages the fuel-air mixture perfectly, allowing air and fuel to enter the engine through valves and mixing them at different levels according to the conditions.

What are the three types of carburetor?

Carburetors are mainly of three different types, they are as follows:

Up-draft Type Carburetors

It is the oldest and the most used type of carburetor. In an updraft carburetor, the air flows upward into the car using the Power Equipment Engine Technology. An updraft carburetor may also require a drip collector

Down-Draft Type Carburator

In order to achieve high speeds and high power, downdraft carburetors can supply large amounts of fuel. It operates on the same principle as other carburetors, fuel comes out through the pipe and is mixed with air due to low pressure created by the two venturis. Air is fed into this type of carburetor from the top, and fuel is fed from the bottom.

Horizontal-Type Carburator

Whenever there is a restriction of space for assembly, this type of carburetor is used. Unlike other carburetors, the jet tube of a horizontal carburetor is placed horizontally, as suggested by its name.

These carburetors work on the basis of a very straightforward principle. Air is drawn into the carburetor through the one end of the carburetor when the carburetor is horizontal.

Are carburators still used?

The use of carburetors in cars stopped in the late 1980s as newer technologies, such as fuel injectors, became more efficient. Until about the early 1990s, very few cars had carburetors.

Currently, they are only used on older cars that still function properly. Automobiles and, to a lesser extent, motorcycles have largely replaced carburetors with fuel injection technology. Compared to fuel injection, carburetors are no longer used in new cars. With fuel injection, you get more mileage, a better warm-up characteristic, more power, and fewer emissions.

A carburetor is still a common feature in small engines for lawn mowers, rototillers, and other items.

Is a carburetor better than a fuel injection?

In comparison to carburetors, fuel injection is the most effective and efficient method for delivering fuel, but carburetors do have their own advantages. The advantage of fuel injection is that it provides more accurate air-to-fuel ratios, however, it is also more expensive and more difficult to repair than carburetors.

When it comes to replacing a carburetor, how much does it cost?

Depending on the model and make of your car, as well as whether you’re replacing a fuel-efficient carburetor or a performance carburetor. Carburetor replacement costs typically range from $500 to $2000. The cost of rebuilding a carburetor, on the other hand, might be only $200 to $500.

Depending on the condition of the carburetor, extra-cost items such as thread repair, booster installation, screw recoloring, etc., may be necessary.

What are two benefits of using a car carburetor?

Two benefits that you can get by using a car carburetor are as follows:

● Fuel injector parts are more expensive than carburetor parts

● Unlike fuel tanks, carburetors are not limited by the amount of fuel pumped through them, allowing cylinders to pull in more fuel and create a denser mixture in the chamber.

What are two disadvantages of using a car carburetor?

Two disadvantages that you can get by using a car carburetor are as follows:

● In extreme low-speed, carburetor mixtures are so weak, that they cannot ignite properly. In order to improve their ignition at these speeds, some arrangement must be incorporated into the carburetor.

● Fuel is consumed more rapidly when carburetors are used compared with fuel injectors because carburetors are heavier.

Why did they stop using carburetors?

Newer technologies, such as fuel injectors, made carburetors less efficient by the late 1980s, so car manufacturers stopped using them. The carburetor was only found in a small number of cars.

With the advent of fuel injection technology, carburetors have largely been replaced by fuel injection systems in automobiles and, to a lesser extent, motorcycles. Carburetors are no longer used in new cars, as they are replaced with fuel injection systems. More power, fewer emissions, better fuel efficiency, and better warm-up characteristics are all benefits of fuel injection.

Are carburated cars reliable?

In general, fuel injection systems are more accurate than carburetors. With this system, fuel is delivered exactly where it is needed, regardless of the conditions, meaning better fuel economy and reliability. The fuel intake ratio cannot be adjusted by carburetors, so they are less accurate.

A carburetor is precise, but not accurate, because air or fuel temperature changes or atmospheric pressure changes cannot be taken into account. . Due to their purely mechanical nature, carburetors are cheaper and more complex than fuel injection

What are the main parts of a carburetor?

A carburetor consists of the following parts:

● Venturi

● Float chamber

● Mixing chamber

● Strainer

● Idling system

● Transfer and Idle port

● Metering system

● Throttle Valve

Is it possible to have a carburetor and a fuel injection system on the same car?

The answer to this particular question will be No, a car that has an engine with a carburetor cannot be fuel injected. An old car with a carburetor can be converted into a fuel-injected car.

The conversion of a carburetor to a fuel injection system replaces the carburetor with a fuel injection system. It is very easy to convert to fuel injection with the help of fuel injection conversion kits.

What is a modern carburetor?

Although carburetors have been stopped being used in the making of modern car engines. A carburetor is still a common feature in small engines for lawn mowers, rototillers, and other items.

Modern carburetors are designed with an automatic choke that uses a thermostat and spring loading to operate. In order to control the engine speed, the throttle valve is the main component. In this case, the valve is operated either mechanically or pneumatically by the accelerator vehicle. The venturi is located downstream of it. There are three modern types of carburetors that are still used in the market, namely

● Constant Vacuum Carburetor

● Constant Choke Carburetor

● Multipe Venturi Carburetor

Conclusion

Hence, from this lesson, we have learned the basics of the carburetor, its working principle, types, and many more. If you have any doubt, please write to us. Check out a very basic understanding of a simple carburetor video , by ADTW [a door through a window],

, by ADTW [a door through a window],