Gas turbine along with it’s different parts, classification, working principles, advantages, disadvantages, etc. are captured in this article. Let’s explore!

What is a Gas Turbine? Definition

Gas Turbine Basics

Let’s understand the basics of a gas turbine. There are various types of prime movers available nowadays. One of the simple power-producing ways is the gas turbine. Some features of gas turbine make it even better and it’s used in power plants as well as in gas turbine engines.

We all know how the turbine is operated.

- In the case of gas turbines, the gas is directed on the blades fixed to the turbine runner in a controlled manner.

- The air is already compressed with the help of a compressor.

- In most cases, the compressor runs on the power generated by the turbine itself.

Gas Turbine Definition

The gas turbine is defined as the combustion engine which produces electricity by expanding natural gas.

- In case of engines, the turbine is used in the turbochargers.

- Turbocharged engines are popular for getting efficient fuel burning and other advantages.

- The gas turbine-powered engines are popular like jet engines etc.

- Mostly they favorable in power generation sectors.

- There are different parts associated with the gas turbine we will check them one by one.

Now let’s see the parts used in the gas turbines and later open cycle and closed gas turbines in brief.

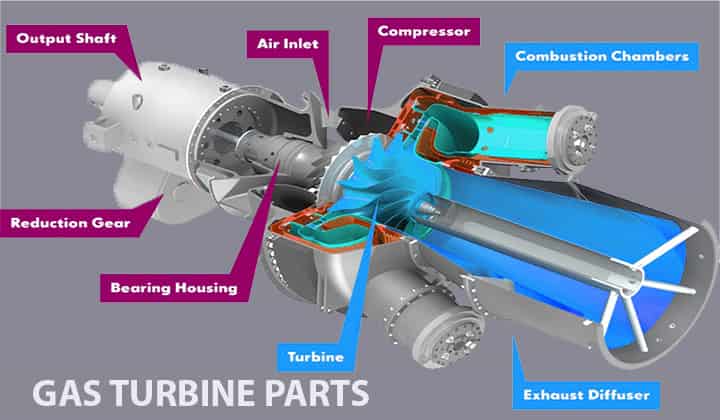

Parts of Gas Turbine

There are few main components,

- Compressor

- Combustion chamber

- Turbine

- Intercooler

- Regenarator

- Reheating unit

Compressor

In a simple gas turbine, the centrifugal compressor is used.

- The features of centrifugal compressor like rugged in construction, a wider range of mass flow rate, and getting more efficiency makes a good choice for the compressor for the gas turbines.

- In case of the gas turbine, compressor and turbine are mound on the same shaft.

That’s how they are useful in turbocharged engines.

Combustion chamber

This one is another important part of the gas turbine. The whole combustion process takes place in the combustion chamber. Why is it important?

- Because the energy is produced in the combustion chamber and later it is converted to work by the turbine.

- The combustion chamber provides complete combustion by mixing fuel, combustible products, and air with uniform temperature distribution.

- It is also known as combustor or burner.

In the combustor, the fuel is mixed with high pressurized air coming from the compressor. The mixture is burned and the high-temperature exhaust gas is passed over the turbine and the turbine rotates.

Turbine

The turbine in case of gas turbines can be reaction or impulse turbines. Turbines drive the compressors and power up the compressors.

- Though the gas turbines have few stages compared to steam turbines because the gas turbines operate at smaller pressure drops.

- The turbine is obviously the main component of the gas turbine.

There are some turbine requirements like,

- high weight,

- high efficiency,

- reliability in operation, and

- long working life.

There are few interesting things about turbines,

- Design is easy and operation is simple with respect to compressors.

- This simple operation is due to the expansion of hot air instead of compression.

- Normally gas turbines utilize axial turbines, although centrifugal turbines are also used for small scales.

High-pressure turbine

The high-pressure turbine is helpful in increasing the product of combustions. As we have already known the turbine and compressor are mounted on the same shaft.

- The high-pressure turbines are responsible for running the compressor.

- About 66% of power is used for powering up the compressor alone.

- The remaining 34% is used for the generation of electricity.

Low-pressure turbine

The low-pressure turbine does the work of power generation. Its shaft is connected to the generator.

- Firstly, the gases come up in the high-pressure turbine, they leave the high-pressure turbines and sent to the combustion chamber for more combustion.

- These burnt gases run the low-pressure turbine.

- Hence the shaft of the turbine is connected to the generator which generates the electricity.

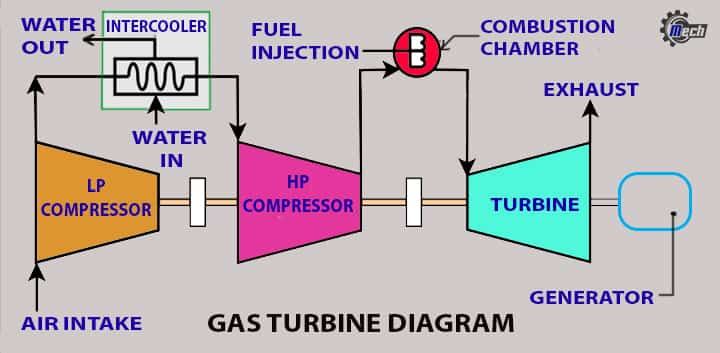

Intercooler

The intercooler is used in case of the compressor.

- To decrease the work of the compressor an intercooler is used.

- It is placed in between the high-pressure compressor and low-pressure compressor.

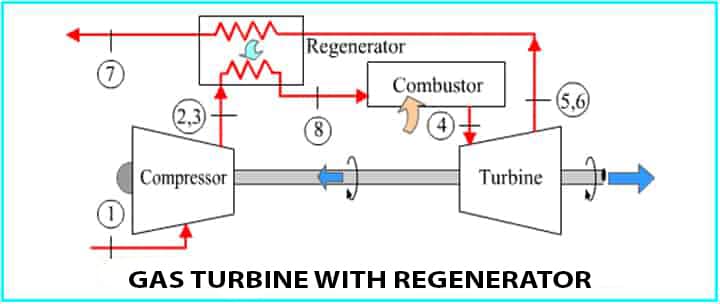

Regenerator

The regenerator work is to preheat the air flowing into the combustion chamber to increase fuel efficiency and decrease fuel consumption.

Reheating unit

This one is the additional mounting available to the exhaust gases coming out from the high-pressure turbines. It heats the products coming from a high-pressure turbine and then transfers them to a low-pressure turbine. Now we have known the parts or components used in the gas turbine. Now let’s see the brief about the types of the gas turbine.

Gas Turbine Diagram

Let’s a very simple schematic diagram of a gas turbine to understand the parts. Gas turbine with intercooler system is given below,

In the gas turbine parts, we have seen gas turbine can have regenerator system as well, so how it looks in schematics? Refer to the below images, to get a basic concept,

Now, this intercooler and regenerator can have in a single gas turbine, and the schematics will be simple, just both the things will be combined.

Types of gas turbine

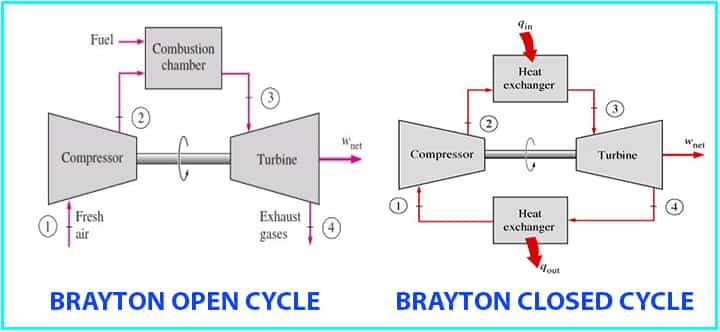

Firstly let’s know simple basic classifications of the gas turbines. Basically, there are two classifications of gas turbines, open cycle gas turbine, and closed-cycle gas turbine. But also, the turbines are classified on the basis of their operation, type of cycle used, etc. Let’s check the gas turbine classifications.

On the basis of cycle of operation

- Open cycle gas turbine

- Closed cycle gas turbine

On the basis of Thermodynamic cycle

- Brayton or Joules cycle

- Atkinsons cycle

- Ericsson cycle

According to applications

- Supercharging of IC engines

- Locomotive propulsion

- Ship propulsion

- Industrial applications

- Aircraft engines

- Electric power generation

According to method of combustion

- Continuous combustions

- Explosion combustion

So, these are all the classifications of the gas turbines. There are various parts in working with the gas turbine. The gas turbines are considered for replacements for cylinder piston type reciprocating combustions. These gas turbines are used in lots of applications as we have seen in the above classifications according to applications of gas turbines.

How Does Gas Turbine Works?

Gas Turbine Working Basics

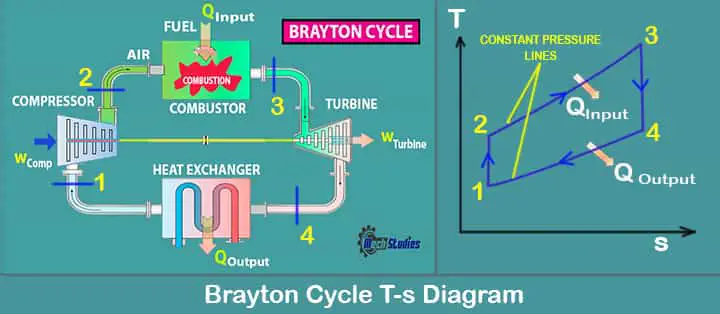

We have already seen various types of gas turbines. However, gas turbines are mainly working in line with Brayton Cycle.

A simple Brayton cycle is shall consists the followings:

Point 1-2 Process of Isentropic compression: In this process, compressor helps to compress the working gas adiabatically from point 1 to point 2.

- Entropy is constant.

- Pressure is increased,

- Internal energy is increased,

- Work required for the compressor, Wcomp = h2 – h1.

Point 2-3 Process of Isobaric heat addition: Heat addition happens at constant pressure that is isobaric process.

- The gas is heated with the help of external heat source.

- It is done at constant pressure.

- The heat addition, Qinput = h3 –h2.

Point 3-4 Process of Isentropic expansion: In this process, heated gas expanded adiabatically in the turbine from point 3 to point 4.

- Due to the expansion of the gas, it will lose energy and same energy will be converted into work and turbine produces work.

- Work produced, WTurbine=h4 – h3.

Point 4-1 Process of Isobaric heat rejection: Here, after the expansion of the gas, it is required to reject the heat from the gas. How to do it? It is simple, by using heat exchanger like point 4 to point 1, the heat can be rejected with a help of a heat exchanger.

- It is done at constant pressure.

- In case of an open system, the heat will be directly released into the atmosphere.

- Heat rejection, QOutput=h4 – h1.

Hence, we have understood that there are two types of work,

- Work done on the compressor Point 1 and 2, Wcomp = Work input required.

- Work done by the turbine Point 1 and 2, W turbine = Work Output.

New Work output = Wnet = W turbine – Wcomp

Now, after learning the basic principle, we will see how does an open and closed gas turbine works.

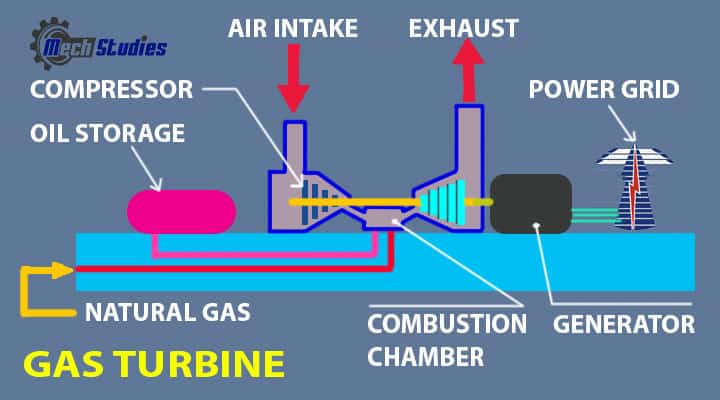

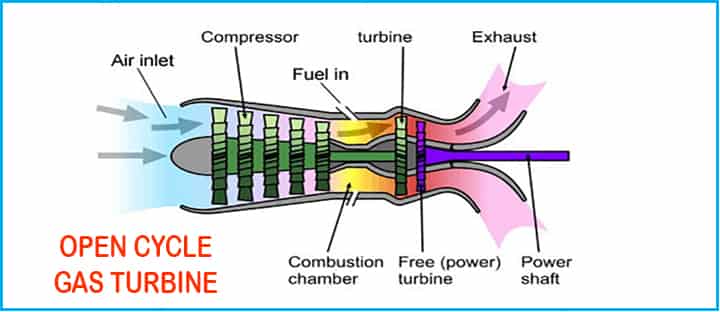

Open Cycle Gas Turbine

The open cycle gas turbine is the simplest constructed version. It has the followings,

- compressor,

- combustion chamber, and

- generator.

Let’s see the working of the open cycle turbine. You can check gas turbine mathematical expressions .

.

Working Principle

So, how does an open cycle gas turbine work? – let’s learn step by step!

- Firstly, the air is sucked into the compressor from the atmosphere.

- The compressed air is then compressed in an adiabatic way generally in the rotary compressor.

- This air is then passed to the combustion chambers.

- As we know the combustion chamber will mix up fuel and the compressed air and burns them.

- These hot gases are now ready and they are directed on the turbine blades.

- The high-temperature gases after getting directed on the turbines get expanded.

- The turbine rotates and the expanded gases are released into the atmosphere.

In the aircraft, open-cycle gas turbines are used where exhaust is released into the atmosphere. Let’s check with a diagram,

The name open cycle gas turbine is because the expanded gas is directed towards the atmosphere. Thus, indicating an open cycle. The expanded gas is wasted and the new fuel and air are burned in the combustion chamber again and the cycle continues. Now let’s check out the closed cycle gas turbine working process.

Closed Cycle Gas Turbine

So, let’s check how does a closed cycle gas turbine works? – let’s learn.

- Firstly, same as that of the open cycle gas turbine, the air is sucked in the compressor.

- Generally, the rotary compressor is used.

- The air is then passed into the combustion chamber.

- The fuel and the high temperature are combusted inside the combustion chamber.

- It increases the volume of the high-temperature air; the exhaust gases are then passed on to the turbine for expansion.

- The turbine rotates and power up the compressor as well as generates electricity while coupled to the generator.

- The expanded gases are transferred to the cooling chamber and it is cooled to the original temperature with the help of circulating water.

- Now again this air is passed into the compressor where the compressor will compress the air and the cycle will repeat continuously.

Check a NICE ANIMATED video from GE Power,

Let’s have a look at the difference between these two types of gas turbines,

Difference between Open & Closed Cycle Gas Turbine

The main differences are, as follows,

| Open Cycle GT | Closed Cycle GT |

| We have seen in the open cycle; the expanded gas is released to the atmosphere. | In case of the closed cycle, the expanded gas is reused after cooling. |

| Gas is replaced continuously as it is an open system | The same gas is continuously circulated as it is a closed system. |

| Working fluid is air. | Apart from air, other gas like helium can be used. |

| Normally used in moving vehicles. | Normally used for stationary applications. |

| Lower maintenance cost. | Higher maintenance cost comparatively. |

Now if you understood both types let’s check the close cycle advantages and disadvantages over the open cycle gas turbines.

Advantages of closed-cycle over open cycle

Advantages of closed-cycle over the open cycle, are as follows,

- Higher thermal efficiency performance

- Reduced size

- Improved heat transmission

- No loss of working medium as the gas is used again and again.

- Greater output

Disadvantages of closed-cycle over open cycle

Disadvantages of closed-cycle over the open cycle, are as follows,

- Closed cycle are more complex.

- The working medium is used again and again so large amount of cooling water is necessary for cooling the expanded gases.

- It is a dependent system.

- Use of large air heater is required and also not economical for moving vehicles as weight per kW developed is high.

Combination with Other Power Plants

The gas turbines can be coupled with other plants like steam power plants and diesel power plants. It can be used to satisfy different purposes for different processes. The combination of gas turbine cycles can be used in the following plants. Combination with the steam power plants

- Used to heat the feed water with exhaust gases.

- Expanding the gases from the supercharged boiler in the gas turbines

- Getting the gases as combustion air in the steam boilers.

Combination with the diesel power plants

- Used in the turbocharging

- Used in the gas generator

- As the compound engine

Now we have known about the combinations the gas turbines can be used. Now let’s check out the advantages and disadvantages of gas turbines.

Advantages of Gas Turbines over Steam Turbines

Advantages of gas turbines over steam turbines, are as follows,

- The fuel cost that is used in the gas turbines is less. Whereas in the steam turbine only fuel is used for generating steam.

- Lubrication is easy as only the lubrication of the main bearing and turbine is needed.

- Maintenance cost is also as compared to the steam turbine.

- Starting and stopping the system is simple.

Let’s have a look at the difference between gas turbines and steam turbines in tabulated form,

| Description | Gas turbine | Steam turbine |

| Basic Cycle | It works based on Brayton Cycle | It works based on Rankine Cycle |

| Working Fluid | It uses air or gas based on the applications | It uses steam |

| Power | Power generation depends on the combustion reaction and work output is in the form of toque or thrust | Power generation depends on the steam expansion and work output is in the form of toque |

| Components | Mainly compressor, combustion chamber, and power turbine are main components. | Boiler & accessories are used to produce the steam for steam turbine. |

| Efficiency | High with respect to steam turbine higher than steam turbines | Less with respect to gas turbine |

| Internal temperature | Very high, around 1500 deg. C based on project requirements. | Comparatively low, like 450-650 deg. C based on project requirements. |

| Lubrication | Lubrication of the is easy as only the lubrication of the main bearing and turbine is needed. | Here, it is complex. |

| Starting | Quick & Easy | Takes more time & Complex |

| Space requirements | Less | High |

| Output | Torque or thrust | Torque |

| Startup and Control | Easy and quick. In case, load changes, control is easy for gas turbine. | Difficult and time taking. In case, load changes, control is complex for steam turbine. |

| Installation cost | Less | High |

| Operating cost | Less | High |

| Water Requirements | Not required | Main working fluid. |

| Maintenance | Easy | Difficult |

| Pollution | More | Comparatively less |

Advantages of Gas Turbines

Advantages are as follows,

- Gas turbines have high reliability.

- A high grade of heat is available.

- It has a high weight to power ratio.

- A wide range of fuel can be used in the gas turbines

- It has the multi-fuel capability and has low emissions.

Disadvantages of Gas Turbines

- Unit sizes are limited within the range of output.

- It has lower mechanical efficiency as compared to the reciprocating engines.

- In case gas fired, it requires high pressure supply or in-house boosters.

- Poor efficiency at low loadings.

- It may need long overhaul periods.

Applications of Gas Turbines

Aviation sector: This kind of turbine is popularly used in the aviation sector. Gas turbines provide the motive power required for jet propulsion.

Electric power generation: The turbines available in electric power generation are steam turbines and gas turbines. Due to its less space, easy mounting, and other advantages gas turbines are also beneficial for electric power generation.

Hence the gas turbines are widely used in medium-sized peak load plants to run intermittently. Various other improvements and modernization is done to make the best use of gas turbines in electric power generations.

Uses in the industry: The size variation of the gas turbines enables it to be used in lots of industrial applications. It includes works like driving compressors, oil refining processes, etc.

Marine applications: The gas turbines are lightweight and compact. In the year of 1970s, they were used by the US Navy to power ship by the gas turbines with 20000 horsepower. They are now used to power other navy vessels.

Locomotive applications: The gas turbines were used to power up the locomotives in 1950-1960s year. But they didn’t have the success due to various reasons over the diesel-powered locomotives.

Automobile applications: These are basically powered engines, widely used in the 1960s. But they didn’t have that much success. Later they were extensively used in supercharging and turbocharging. They became popular with turbocharging and they are still used in turbocharged vehicles.

Most importantly they are becoming more and more useful in electric power generation sectors. The advancements in gas turbines are making them even more useful and effective and various applications. The development of computational fluid dynamics, finite element analysis and advanced materials are helping gas turbines.

Gas Turbines Project Examples

There are several gas turbines projects already executed across the word, a list is added for reference,

- Surgutskaya GRES-2, Russia, Installed capacity of 5,597 MW

- Futtsu power station, Japan, Installed capacity of 5,040 MW

- Kawagoe power station, Japan, Installed capacity of 4,802 MW

- Dah-Tarn (Tatan) power plant, Taiwan, Installed capacity of 4,384 MW

- Chita thermal power station, Japan, Installed capacity of 3,996 MW

- Anta Thermal Power Station, India, Installed capacity of 413 MW

- Dholpur Combined Cycle Power Station, India, Installed capacity of 330 MW

- IPGCL Gas Turbines Power Station, India, Installed capacity of 270 MW

- Pampore Gas Turbines Station, India, Installed capacity of 175 MW

Manufacturers of Gas Turbines

There are so many gas turbine manufacturers are available across the world, few of the main suppliers are captured below,

are available across the world, few of the main suppliers are captured below,

- Kawasaki

- Mitsubishi

- Siemens Energy

- Caterpillar

- Capstone

- MAN

- OPRA

- Centrax

- BHEL

Codes & Standards for Gas Turbine

API STD 616 – Gas Turbines for Petroleum, Chemical, and Gas Industry Services,

SO 10494:2018 is applicable to turbines and turbine sets for power plant and industrial applications (e.g. stationery),

ISO 2314:2009 – Gas turbines — Acceptance tests,

ISO 3977-3:2004 design requirements for the procurement of all applications of gas turbines,

Codes & Standards for Gas Turbines

Conclusion

Hence, we have got a basic idea about the gas turbines, its parts, types, working principle, advantages, disadvantages, etc. Any doubt, please let us know. Check out our few most interesting articles,

Reference Articles