Do you have any idea about the industrial ventilation system? In this article, we will learn the basics of a ventilation system along with its definition, meaning, how does ventilation system works, parts, types, examples, etc. Let’s explore!

What is Industrial Ventilation System? Definition & Meaning

Industrial Ventilation System Meaning

The Ventilation system has an important role while constructing any closed structure or building for ages. This is a system used in commercial buildings or residential buildings or any industrial buildings that drive fresh outdoor into the building inside and eliminate the contaminated indoor air into the outside or atmosphere. This can be achieved either with the help of,

- by natural means (Wall window) or

- by mechanical means (blowers or fans) or

- by the combination of both, i.e., hybrid ventilation.

- In general, ventilation is used to control the vulnerability to harmful airborne pollutants while in big industries it helps to remove the dust, fumes, vapors and keep the work temperature and humidity at the comfort levels to make the working environment clean and healthy.

- The Ventilation system also helps in reducing potential fire and explosion hazards.

Ventilation Definition

The ventilation system is defined as the process by which fresh outdoor air can be introduced inside a room and able to eliminate the contaminated particles or air by natural or mechanical means. In this article, we shall get to know the actual ventilation system, uses, working philosophy, advantages, disadvantages, and many more, so let’s learn!

You can explore AHU video with Site Tour

Parts of Ventilation System

The parts of the ventilation system depend on the types of the system considered as well as the applications. Few of them are illustrated to have a rough idea,

Supply fans

The supply fan means the fan which can supply air.

- These fans are used to supply air into the room to be ventilated.

- It can be axial fans or centrifugal or any other types based on requirements.

- It can be ducted or non-ducted as well.

Exhaust fans

The meaning of an exhaust fan is very simple. The fan which can exhaust air is called an exhaust fan.

- These fans are used to exhaust air from the room to the atmosphere.

- Exhaust fans may be centrifugal or axial or other types as required.

- It can be ducted or non ducted as well.

Supply and Exhaust louvers

Louver means metallic equipment which has a number of horizontal blades. These blades are normally fixed type and air passes through the gaps between blades. The louver which is used to supply the air is called supply louver and the louver which is used to exhaust the air is called exhaust louver.

- Supply and exhaust louvers are used to at the supply and exhaust respectively.

- It stream lines the air path.

- In many places, only exhaust fans or supply fans are required. In that scenario, supply louvers with exhaust fans or supply fans with exhaust louvers are provided.

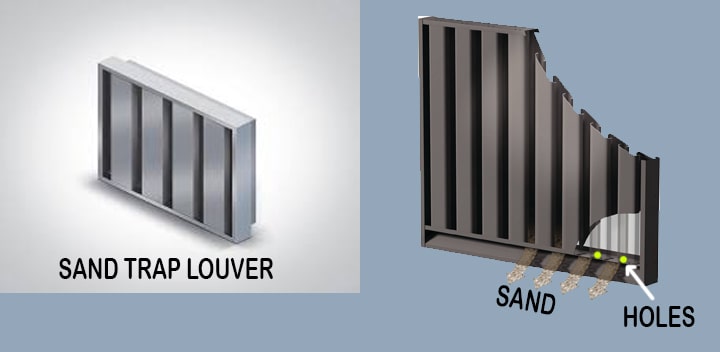

Sand Trap Louver

It is a special type of louver that has several vertical metallic strips with zig-zag passages, used to filtrate the air from dust particles or sand.

- This is one kind of louver mainly used in dusty area which particularly consists of sand particles.

- Normally used in the gulf region and desert areas.

- It is mounted at the inlet of duct in the supply system, so that sand particles will be removed.

- When air with sand particles are passing through the sand trap louver, air can easily pass through but sand particles cannot pass due to its weight.

- Sand particle strikes the zig-zag passages and falls down.

- In the bottom side of sand trap louver, there are holes to remove sand particles automatically.

- Air velocity through the louver is 1.2 m/s to 1.5 m/s.

Ducting

- Like air conditioning system, ventilation system may have ducting, diffusers, grilles etc. for the proper circulation of ventilated air.

- This duct can be rectangular or round shape.

- Air velocity through duct is limited to 10-12m/s.

- Air velocity through diffusers or grilles is normally considered as 2.5 m/s – 4.5m/s, depending on the project requirements.

Gravity louvers

- In many ventilated systems, gravity louvers are provided in combination with supply fans. It operates based on gravity.

Fire dampers

- Like air conditioning system, ventilation system may have fire dampers. There are many places where ventilation system needs to be crossed through fire-rated walls.

- In this case, fire dampers are required to provide to stop the air flow from one room to another in case any fire happens.

Filters

- Different kinds of filters are provided to filtrate the air from the contaminants present in the air.

- Prefilters are normally provided.

- Bag filters are also provided if the application required good quality of air.

Roof extractors & Turbo Ventilators

- As the name suggests, it is basically mounted on the roof.

- It has exhaust fan with roof cover.

- It works like normally exhaust fans.

Turbo ventilator, right side image in the above. This ventilator, like a roof extractor, is normally installed on the roof of the buildings and it doesn’t require any electricity. Hence, no power consumption or no running cost.

Air washer & Unitary air filtration system

- When a large capacity of ventilation is required and its temperature needs to make it down, we use Air washer & Unitary air filtration system.

- It has a limitation of humidity.

- Louvers, filters, moisture eliminators, water tank, fans, pumps, etc. are the main parts of Air washers & unitary air filtration system.

We will try to understand all the different parts by explaining different types of ventilation systems.

Types of Ventilation System & How it Works?

In today’s times, ventilation is necessary for good health and to create a healthy environment to live in. Ventilation is the movement of air into, through, and out of any building, the most important elements are,

- ventilation rate,

- airflow direction, and

- air distribution or airflow pattern.

The factors needed to be taken into account while designing the ventilation includes the nature of operations or activities, the rate of occupancy, the design of the structure, and the rate of generation of hazardous substances. The different types of ventilation systems are as follows:

- Natural Ventilation

- Mechanical ventilation

- Energy Recovery & Heat Recovery Ventilators

- Hybrid Ventilation

Let’s learn all types of ventilation systems in brief to have a basic concept.

Natural Ventilation System

What is Natural Ventilation System?

The benefit of outdoor air for natural ventilation merged with natural cooling strategies and the use of sunlight have been essential constituents of architecture since older times. It is one of the most practical ways technology in a building for passive cooling.

Natural ventilation depends on forces such as wind and thermal buoyancy to bring outdoor air through the building’s openings. In earlier times, all the historical monuments were naturally ventilated. The major aspects that play an important role in natural ventilation are human behavior, climate, and building design.

- These purpose-built openings comprise façade, windows, doors, wind towers, solar chimneys, trickle ventilators, etc.

- Energy consumption is also reduced by up to 20 to 25 percent due to the Natural Ventilation system. That is why it is a relevant solution for minimizing the energy usage, cost and keeping the internal room climate healthy and clean.

- We may think of opening the windows of our room when we hear about natural ventilation however, in reality, it is more complex than how we see it.

- Natural ventilation is also uncontrollable and unpredictable, and hence in some areas where there is more air contamination outside in the surroundings than inside, in that case, natural contamination can work contrarily. It will not only ventilate the room but also will contaminate it.

- This polluted air can harm our people’s health-giving various diseases. Since there is no significant control to reduce the polluted air, so nowadays in most cases natural ventilation systems are replaced by mechanical ventilation.

- If the designs are correct and accurate, natural ventilation can be authentic, in particular, if it’s combined with the togetherness of Mechanical and Hybrid (Mixed-mode) ventilation system.

- However, some of these designs may be difficult to achieve without errors and after that, may be more costly to construct.

Types of Natural Ventilation

The two most commonly used natural ventilation methods are:

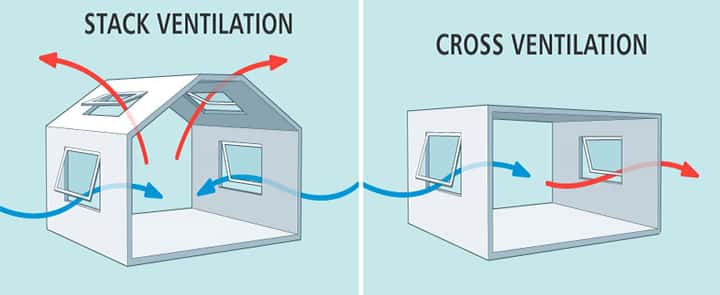

Cross-Ventilation or Wind-Based ventilation

Wind-Based ventilation is effortless. It is also called Unilateral Ventilation and Cross Ventilation. Wind-Based ventilation depends on the wind’s direction and its flowing relation with doors, windows, and other openings of the building. Although it should be kept in mind that Wind-Based ventilation is not practical in locations where there is a lot of dust particles and contamination.

Stack Ventilation or Buoyancy-Driven ventilation

Buoyancy-Driven ventilation is also called stack ventilation. The temperature of indoor air and the temperature of outdoor air are different. As we all know the difference in the temperature leads to differences in densities. Since the warmer air has lower density and more buoyancy in comparison to the cooler air which has greater density, the warmer air rises upwards and the cooler air remains downwards eventually keeping the ventilation.

Advantages of Natural Ventilation

- Natural ventilation can provide a greater ventilation level economically due to the application of natural sources and large openings. If heating is not required it can be energy effective.

- Natural ventilation is the oldest ventilation system that has survived for more than 1000 years. Natural ventilation is also a solution to keep the environment sustainable. Since it requires no electrical energy for its use, it is thus cost-efficient.

- The maintenance requirement is usually very little.

- Natural ventilation does not demand extra space for a network of ducts or plant rooms. It can also be used to achieve higher levels of sunlight during the daytime.

Mechanical Ventilation System

What is Mechanical Ventilation System?

Mechanical ventilation is carried out by mechanical fans. These fans can be installed directly on walls, windows, or in air ducts through which air can pass in and out from the room through other fans. It is also called Forced ventilation. In hot and humid climate temperatures, it may be essential to decrease or prevent intrusion rather than interstitial compression, and hence a positive pressure mechanical ventilation system is generally used.

- Contrastingly, in colder atmospheres, exfiltration should be kept away, and accordingly a negative pressure mechanical ventilation system is used to prevent intermediate condensation.

- Some examples of negative pressure mechanical ventilation systems are the bathroom, toilet, kitchen, etc. where the pollutants are locally produced.

- In a positive pressure system, the air in the room leaks out through different openings while in the negative pressure system, the room air is filled by taking the outside air.

- In recent times, Mechanical ventilation systems are largely used in developing and high-income countries.

The different types of mechanical ventilation are as below:

Wet Type Ventilation (Evaporative Cooling)

Evaporative cooling or wet type system is used in many places for ventilation. When a large capacity of cooled air is required mainly for big plants, like power plants or steel plants, these kinds of units have opted. Mainly two types of system are mostly used,

- Air washer units (AWU)

- Unitary Air Filtration system (UAF)

Air washer units (AWU)

In this unit, there are various parts like fills, filters, moisture eliminators, distribution plates, air washer tank, etc. are the main parts. In addition to these, air washer pumps are there to circulate the water. Cooled and filtered air from the Air Washer unit shall be distributed to the required areas by means of ducting through fans.

- Moisture eliminator screen shall be used after the water flooded filters to eliminate the carryover of moisture.

- Centrifugal fan is used to circulate the air.

- One (1) no. water tank complete with make-up connection with float valve, quick fill connection, drain connection with valve and overflow connection with siphon shall be provided.

- The casing front shall be provided with an air inlet louver.

- This unit is enclosed by sheet metal.

- Water will be recirculated by means of pumps.

This cool air is circulated to the areas and picks up the heat and finally exhausted to the atmosphere. The quantity of air exhausted air from the areas shall be kept a little lower than the supply air quantity (usually 65‑75% of the supply air is exhausted) and it helps to maintain a little overpressure within the area. This overpressure also helps to reduce infiltration of outside hot and dusty air into the area.

Unitary Air Filtration system (UAF)

Unitary Air Filtration (UAF) is used when the capacity requirements are comparatively less with respect to air washer units. It has a water repellent nylon filter with a water spray arrangement over the surface of it continues to clean the filter.

- Moisture eliminator screen shall be used after the water flooded filters to eliminate the carryover of moisture.

- Centrifugal fan is used to circulate the air.

- One (1) no. water tank complete with make-up connection with float valve, quick fill connection, drain connection with valve and overflow connection with siphon shall be provided.

- The casing front shall be provided with an air inlet louver.

- UAF is enclosed by sheet metal.

- Water will be recirculated by means of pumps.

Dry Type Ventilation

It can be categorized into five types,

- Pull type ventilation (Exhaust only)

- Push type ventilation (Supply only)

- Push-pull type ventilation (Supply & exhaust or balanced ventilation)

- Balanced Ventilation

- Hybrid ventilation

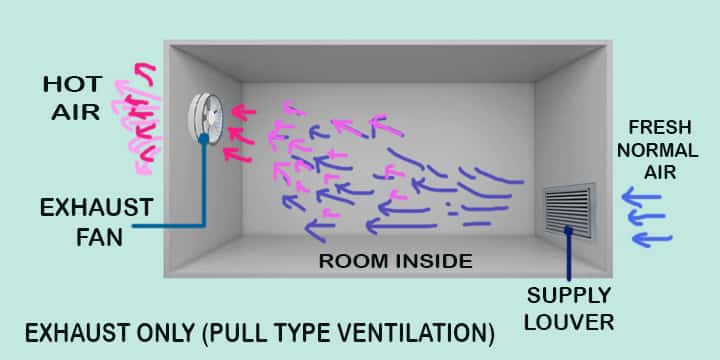

Pull Type Ventilation (Exhaust-Only)

Exhaust-Only ventilation works by decreasing the pressure inside the building. As such, it doesn’t have any components or parts to pull the surrounding air into the room. The air balances the pressure after entering the building through the leaks of the building structure.

- Exhaust-Only ventilation systems are inexpensive to install and comparatively straightforward.

- Exhaust ventilation systems typically contain a single fan or multiple located centrally in the required room for its working, and thus it has lower operating costs as well.

- The numbers of fans are based on requirements and it can be multiple as well based on the capacity, areas, etc.

- Normally exhaust fans are at higher elevation and it is associated with supply louvers.

- Supply louvers are kept at lower elevations.

- Although, in warmer areas where the climate is usually high, the moisture may cause difficulties, and hence they are only suitable for colder places.

Exhaust Only Ventilation Pros

- Less expensive.

- Low operating cost.

- Easy to install.

- Nos of equipment is less.

- The location of exhaust fans can be selected based on requirements.

- Can be used in ventilation system where negative pressure is accepted.

- Good in cold climates, as well in high-temperature climates.

Exhaust Only Ventilation Cons

- Cannot create slight over pressure.

- In case, the fan is installed near to the door or windows, there is a possibility that the fan sucks outside air instead of inside air, which hampers the ventilation system.

- As it creates negative pressure, if the room is not sealed properly, there may be a chance of entering pollutants inside the room.

- Maintenance is required for exhaust fans.

- Electricity is required to operate the exhaust fans.

- It cannot have filtrate air into the rooms.

- It cannot control the moisture content.

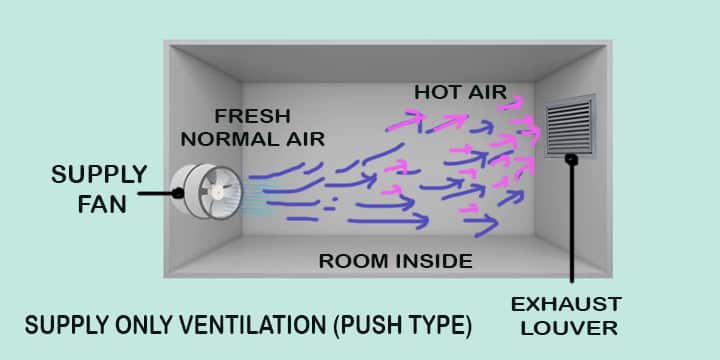

Push Type Ventilation (Supply-Only)

This Supply-Only ventilation system includes a fan and a duct system to pressurize the air in the room and force the outdoor air into the room. The inside air breaks free outside through the artificial exhaust fan ducts and wall leaks.

At times they may have a Central Fan Integrated (CFI) system, but the installation and maintenance costs increase. Supply ventilation systems have more control than exhaust ventilation systems over the air that enters the house.

This system also reduces the number of outdoor pollutants coming inside through pressurizing.

Supply Only Ventilation Pros

- Less expensive.

- Low operating cost.

- Easy to install.

- Nos of equipment is less.

- The location of exhaust fans can be selected based on requirements.

- Can be used in ventilation system where negative or positive pressure is required.

- Good in cold climates, as well in high temperature climates.

- It can provide filtered air as supply fans can have a filter which restricts entrance of pollutants.

Supply Only Ventilation Cons

- Filters shall be provided additionally and regular maintenance is required.

- Maintenance is required for supply fans.

- It cannot control the moisture content.

- Electricity is required to operate the exhaust fans.

Balanced or Push-Pull Type Ventilation (Supply & Exhaust Fans)

If we combine Exhaust-Only ventilation and Supply-Only ventilation system then we can produce a balanced ventilation system.

- Numbers of supply fans and exhaust fans are selected based on the size of building as well as air flow requirements.

- Normally supply fans are mounted at lower elevation.

- Exhaust fans are located at higher elevations, as hot air always tends to go at a higher elevation.

- To make the room slightly positive, total capacity of supply fans are slightly higher than the total capacity of exhaust fans.

Supply Exhaust Ventilation Pros

- Best dry ventilation system.

- Suitable for all climates.

- Can make over pressure.

- Numbers of supply fans and exhaust fans are selected based on requirements.

Supply Exhaust Ventilation Cons

- Maintenance is high as there are supply and exhaust fans.

- It cannot control the moisture content.

- Installation cost is high with respect to other ventilation system.

- As there are many supply and exhaust fans, power consumption is high.

- Many fans results in high noise level.

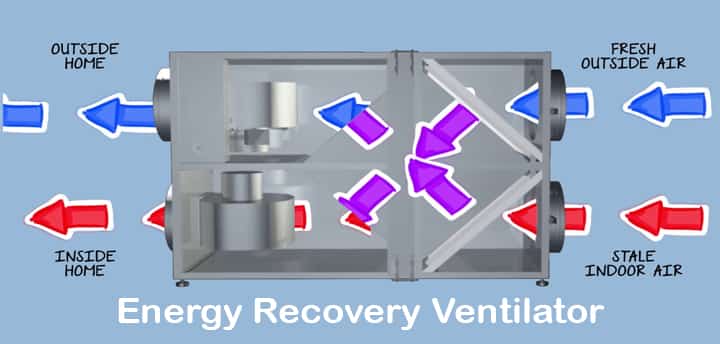

Energy Recovery & Heat Recovery Ventilators

This is the most commonly used in many buildings with Heat Recovery Ventilator (HRV).

In this system, the rate of flow of air indoor exhaust and outdoor supply is almost equal. Balance ventilation systems work well in both mixed climates and hot climates. However, they are most expensive than supply or exhaust ventilation systems to install and operate. Balanced ventilation has further two types i.e.

- Energy Recovery Ventilator (ERV)

- Heat Recovery Ventilator (HRV).

ERV and HRV

Energy and Heat recovery ventilation systems provide a systematic way of ventilating while reducing great energy and heat loss. Both ventilation systems include a heat exchanger and one or more fans to thrust the air through the machine and controls. The way heat exchangers work is the only difference between these two.

Advantages of Mechanical Ventilation

- Despite of the impacts of variable wind and ambient temperature, Mechanical ventilation is said to be more practical in delivering the designed flow rate and improving the air quality of the room.

- Mechanical ventilation can be effortlessly consolidated into the air-conditioning because of which the temperature and humidity can be managed. It can be operated anywhere where there is enough electricity.

- Filtration systems that remove harmful gases, micro-organisms, odors, and vapors can also be installed in a mechanical ventilation system.

- The airflow direction from a particular source to a particular source can also be controlled in a mechanical ventilation system.

Drawbacks of Mechanical Ventilation

- Mechanical ventilation systems often get broken down due to numerous reasons such as equipment failure, poor design, poor maintenance, or incorrect operations. They do not work up to their full potential due to such reasons.

- The cost of maintenance for operations, which is required timely and installation costs are very high.

- The performance of mechanical ventilation systems can be negotiated if it isn’t properly installed or maintained due to high operational costs.

- Considering all these factors, a mechanical ventilation system rather than being an important machine for infection control, may result in the spread of infectious diseases in healthcare facilities.

Hybrid Ventilation

What is Hybrid Ventilation?

Hybrid ventilation is a system that is quite a new concept and which provides a secured internal environment using the features of Natural ventilation and Mechanical ventilation systems and hence is also called a mixed-mode ventilation system.

- The leading difference between conventional ventilation systems and hybrid ventilation systems is that the hybrid ventilation system can be equipped with control systems that can automatically switch between natural and mechanical ventilation systems is to achieve lower energy consumption and a sustainable environment.

- Hybrid ventilation depends upon the natural forces to produce the wanted flow rate. The role of Mechanical ventilation is notable when the flow rate of natural ventilation is very low.

- In locations where the natural ventilation doesn’t fulfill the required solution at that time, mechanical exhaust fans can be installed to increase the ventilation rate.

- A typical example of Hybrid ventilation is in Healthcare buildings (hospitals) where there are patients with airborne infections. However, it should be used with proper alertness in which the exhaust fans should be installed in a place like a wall or a ceiling where it directly throws out the inside air into the outside environment. Hybrid ventilation is also used in offices, schools, and multi-family buildings.

- Experts assume that the most promising systems for the near future will be demand-controlled Hybrid ventilation technologies.

- Another substitute option for hybrid ventilation systems is whirlybirds (wind turbines) which directly require a roof exhaust system to increase the ventilation of the whole building without the use of electricity.

Advantages of Hybrid Ventilation

- Since it takes advantage of the natural and mechanical ventilation systems it results in decreased energy consumption and initial cost as compared to mechanical systems.

- Hybrid ventilation is also more powerful in fulfilling IAQ (Indoor Air Quality) and other heating/cooling requirements as compared to natural ventilation systems.

- Hybrid ventilation system consists of many operating parts but a failure in one part does not affect the whole system. It also self-adjust to the change in airflow thus reducing operation and maintenance cost.

Industrial Ventilation System Calculation Example – Pump House

We will learn the calculation of the ventilation system with a simple example. Let’s consider a pump room and it has a few pumps which are running and we have to ventilate this pump room. So, how to calculate it?

The calculation of ventilation shall be based on two methods, and selection is based on the maximum value between that two methods. Here, we will discuss a dry ventilation system for easy understanding!

Heat Load Method Ventilation Calculation

Step-1: Dissipation of Heats

- Pump room has equipment which are running, motors are running. As motors are running, it will dissipate heat into the rooms and will increase the temperature of air.

- The wall, doors, windows etc. of the pump room will take solar heats and increase the temperature.

- This room may have lighting which also dissipates heats into the room.

- So, it is required to get the total heat dissipation.

- Let’s consider, total heat dissipation, q = 14.5 kW.

Step-2: Temperature difference

Remember we can not reduce the temperature by this ventilation system. For example, if the atmospheric temperature is 40 deg. C, we cannot reduce it to 35 or even 38 deg. C as well. What does this ventilation system do, it can specify that the room temperature can not go beyond 43 deg. C or 45 deg. C.

- It means we are restricting the temperature to 3 i.e. 43-40 deg. C or 5 i.e. 45-40 deg. C above the atmosphere.

- This 3 or 5 is the temperature difference.

- Here, we will consider, 5 deg. C

Step-3: Air quantity calculation

Air quantity, Q

We know,

Heat, q

- q = m x Cp x Δt

- q = ρ x Q x Cp x Δt [m = ρ x Q]

- Q = q / (ρ x Cp x Δt)

Where,

- Q = air quantity in m3/s

- q = heat dissipation in kW = 14.5 kW

- ρ = density of air in kg/m3 = 1.2 kg/m3

- Cp = Specific heat of air, = 1.005 kJ/kg K or kJ/kg K deg. C

- Δt = temperature difference = 5 deg. C

So, Q =?

- Q = q / (ρ x Cp x Δt)

- Q = 14.5 / (1.2 x 1.005 x 5)

- Q = 2.4 m3/s

- Q = 8612 m3/hr

Air Changes per Hour Method Ventilation Calculation

Let’s see how to do ventilation calculation by the air changes per hour (ACPH). The steps are as follows,

Step-1: ACPH Selection

Different areas have different air changes per hour as per standards and sometimes it is project/client specific as well. For pump house ventilation, normally we consider 10 – 12 air changes per hour. Let’s consider 10 ACPH for example.

Step-2: Room volume calculation

As this ventilation is associated with air changes per hour, to calculate the air quantity we have to get the volume first. Volume, V,

V = L x W x H

Where,

- L = Length of room

- W = Width of room

- H = Height of room

Let’s consider, the pump room size is 20m x 7.5m x 6m.

Volume, V = 20 x 7.5 x 6 = 900 m3

Step-3: Air quantity calculation

Air quantity, Q’,

- Q’ = Volume x ACPH

- Q’ = V x ACPH

- Q’ = 900 x 10

- Q’ = 9000 m3/hr

Air Quantity Selection

Now, we have got two different values of air quantity in two different methods.

Main criteria: Air quantity is selected which one is higher among heat load and ACPH basis.

Selection:

- Air quantity, Q (Heat load method) = 8612 m3/hr

- Air quantity, Q’ (ACPH method) = 9000 m3/hr

Q'<Q

Hence, Air quantity, Q’ (9000 m3/hr) is selected.

How to Select Ventilation System Equipment?

As it’s a small pump room, we have considered a dry ventilation system with slight overpressure.

- Supply through Supply fans

- Exhaust through exhaust fans

Selection of Supply Fans

- Selected Total Supply Air quantity, Q’ = 9000 m3/hr

- Nos. of fans, n = 3 (based on the pump room layout)

- Each supply fan capacity = Q’/n = 9000/3 = 3000 m3/hr

- Supply fans : 3 nos. x 3000 m3/hr

Selection of Exhaust Fans

- Selected Total Exhaust Air quantity, Qe = 80% of Selected total supply air quantity,

- Selected Total Exhaust Air quantity, Qe = 0.8 x 9000 m3/hr = 7200 m3/hr

- Nos. of fans, n = 3 (based on the pump room layout)

- Each exhaust fan capacity = Qe/n = 7200/3 = 2400 m3/hr

- Exhaust fans : 3 nos. x 2400 m3/hr

Note: Supply normally is provided at a lower elevation and exhaust is provided at a higher elevation to have proper circulation.

Pump House Ventilation System Calculation Summary

Let’s summarize the ventilation calculation of pump room, as below:

| A | INPUTS | |

| 1 | Name of Room | Pump Room |

| 2 | Room Size, L x W, (m x m) | 20 x 7.5 |

| 3 | Room Height (H), m | 6 |

| 4 | Equipment Heat Load, q, in kW | 14.5 |

| B | AIR QUANTITY (HEAT LOAD METHOD) | |

| 1 | Equipment Heat Load, q, in kW | 14.5 |

| 2 | Density of air (ρ) in kg/m3 | 1.2 |

| 3 | Specific heat of the air (Cp), in kJ/kg K or kJ/kg K deg. C | 1.005 |

| 4 | Temperature difference (Δt) in deg. C | 5 |

| 5 | Air Quantity, Q = q / (ρ x Cp x Δt) in m3/s | 2.4 |

| 6 | Air Quantity, Q = q / (ρ x Cp x Δt) in m3/hr | 8612 |

| C | AIR QUANTITY (ACPH METHOD) | |

| 1 | Room Volume (V = L x W x H), m3 | 900 |

| 2 | Air Changes per Hour (ACPH) | 10 |

| 3 | Air Quantity, Q = V x ACPH, m3/hr | 9000 |

| D | AIR QUANTITY SELECTION | |

| 1 | Air Quantity by Heat Load method, m3/hr | 8612 |

| 2 | Air Quantity by ACPH method, m3/hr | 9000 |

| 3 | Selected air quantity (whichever is higher), m3/hr | 9000 |

| E | SUPPLY SYSTEM | |

| Based on the application, the supply system needs to be considered with supply fans | ||

| 1 | Supply air quantity, Qs m3/hr | 9000 |

| 2 | Nos. of supply fans (N), based on the area/layout, | 3 |

| 3 | Supply fan capacity (Qs/N), m3/hr | 3000 |

| F | EXHAUST SYSTEM | |

| Based on the application, the exhaust system needs to be considered with exhaust fans and it is recommended to exhaust 80% of the supply air to have slight overpressure. It can be 90% as well. | ||

| 1 | Exhaust air quantity, Qe = Qs x 80% in m3/hr | 7200 |

| 2 | Nos. of exhaust fans (N’), based on the area/layout, | 3 |

| 3 | Exhaust fan capacity (Qe/N’), m3/hr | 2400 |

Industrial Ventilation System Calculation Example Pantry

To have a clear understanding, one more example has been tabulated, as follows:

| A | INPUTS | |

| 1 | Name of Room | Pantry |

| 2 | Room Size, L x W, (m x m) | 5 x 4 |

| 3 | Room Height (H), m | 3 |

| 4 | Equipment Heat Load, q, in kW | No |

| B | AIR QUANTITY (HEAT LOAD METHOD) | |

| 1 | Equipment Heat Load, q, in kW | 0.5 |

| 2 | Density of air (ρ) in kg/m3 | 1.2 |

| 3 | Specific heat of the air (Cp), in kJ/kg K or kJ/kg K deg. C | 1.005 |

| 4 | Temperature difference (Δt) in deg. C | 5 |

| 5 | Air Quantity, Q = q / (ρ x Cp x Δt) in m3/s | 0.083 |

| 6 | Air Quantity, Q = q / (ρ x Cp x Δt) in m3/hr | 298 |

| C | AIR QUANTITY (ACPH METHOD) | |

| 1 | Room Volume (V = L x W x H), m3 | 60 |

| 2 | Air Changes per Hour (ACPH) | 6 |

| 3 | Air Quantity, Q = V x ACPH, m3/hr | 360 |

| D | AIR QUANTITY SELECTION | |

| 1 | Air Quantity by Heat Load method, m3/hr | 298 |

| 2 | Air Quantity by ACPH method, m3/hr | 360 |

| 3 | Selected air quantity (whichever is higher), m3/hr | 360 |

| E | SUPPLY SYSTEM | |

| Based on the application, the supply system needs to be considered as conditioned air | ||

| 1 | Supply air quantity, Qs m3/hr | 360 |

| 2 | Nos. of supply fans (N), based on the area/layout, | No |

| 3 | Supply fan capacity (Qs/N), m3/hr | No |

| F | EXHAUST SYSTEM | |

| Based on the application, the exhaust system needs to be considered with exhaust fans | ||

| 1 | Exhaust air quantity, Qe in m3/hr | 360 |

| 2 | Nos. of exhaust fans (N’), based on the area/layout, | 1 |

| 3 | Exhaust fan capacity (Qe/N’), m3/hr | 360 |

Let’s explore how to calculate the ventilation system of Diesel generator acoustic enclosure for one more example.

Ventilation System Calculation for Diesel Generator Acoustic Enclosure

Design Considerations for DG set

The design considerations for DG ventilation shall be as follows:

- The maximum temperature rises above atmosphere, normally it is considered as 5°C. Many cases, it is considered as 3°C.

- Maximum atmospheric temp. = 50 °C (for example)

Explanation for Diesel Generator Acoustic Enclosure Ventilation

This ventilation system confirms that in extreme condition, due to loading or working of DG set, the temperature will be reached 50+5°C or 50+3°C with respect to 5°C or 3°C temperature rise respectively.

- We will consider 5°C temperature limitation above atmosphere in our calculation.

- This ventilation system cannot reduce the temperature, it can only limit the temperature rise.

- Each diesel engine has two parts (engine & alternator) which emits heat and the same needs to be taken care in the calculation

- If the temperature rise is changed to 2 °C, then air quantity will be increased drastically.

Air quantity requirements with respect to temperature rise,

Air quantity at 2°C > Air quantity at 3°C > Air quantity at 5°C

Ventilation Calculation for Diesel Generator Enclosure

As heat load is the main criteria to temperature increase, we have to calculate the ventilation requirements based on heat load method. Let’s consider, DG set rating 370 kVA and power factor is 0.85 with an efficiency about 94%.

Step#1 Find out the total Equipment Heat Dissipation Loads

Total loss or heat generation shall be, q

Heat, q = q1 (heat loss from engine) + q2 (heat loss from alternator)

Let’s find out the value of q1,

- Rated power, Prated = 370 kVA

- Power factor, P.F = 0.85

- Efficiency, n = 94%

- Loss =100% – 94% = 6%

- q1 = heat dissipation or heat loss in kW = Prated x P.F x Loss in kW= 370 x 0.85 x 6/100 = 18.87 kW

The value of q2 shall be taken out from the catalogue, say it is 36 kW.

So, q = q1 + q2 = 18.87 + 36 = 54.87 kW

Step#2 Apply Ventilation Calculation Formula

As per ventilation calculation formula, we know

- Q = q / (ρ x Cp x Δt)

Where,

- Q = air flow rate in m3/s

- q = 54.87 kW

- ρ = air density = 1.2 kg/m3

- Cp = Specific heat of air, = 1.005 kJ/kg K deg. C

- Δt = temperature limitation = 5 deg. C

So, Q =?

- Q = q / (ρ x Cp x Δt)

- Q = 54.87 / (1.2 x 1.005 x 5)

- Q = 9.1 m3/s

- Q = 32,758 m3/hr

A small margin approx. 5-10% can be taken for safer side.

Step#3 Add the Additional Air Requirements for Combustion

So, the required air flow rate is equal to 32,758 m3/hr. This is not the final air requirements, as there will some combustion air and the same needs to be taken up to calculate the total air requirements for the ventilation system.

This combustion air depends on the type of diesel engine as well as manufacturer, hence, this data also has to be taken from the catalogue. Let’s say this value, QCA = 2000 m3/hr

So, total ventilation air Qt

Qt = Q + QCA

Qt = 32,758 + 2000 m3/hr

Qt = 34,758 m3/hr

Ventilation in Air Conditioning System

Does Ventilation Require in Air Conditioning System?

Do you know that ventilation is required in an air conditioning system? Let’s try to understand. In an air conditioning system, continuous recirculation of air decreases indoor air quality (IAQ) due to many pollutants. Hence, outside fresh air is essential for making the air fresh and clean. This is nothing but a ventilation system.

- It is mandatory for the areas where people will be regularly accommodated.

- All medical applications, offices, hotels, etc.

- In our split air conditioners or window air conditioner (installed at home) don’t have this ventilation provision but due to door leakages or window openings, we get sufficient amount of fresh air.

- Lack of ventilation in the air conditioning system results headaches, poor IAQ.

- Long-term lack of ventilation system may give serious health impact due to lack of oxygen in lungs.

How Does Ventilation Requirements Calculate in AC system?

There are some criteria to select the ventilation requirements in the AC system and whichever value is higher, the same needs to be considered. There are guidelines in ASHRAE which is widely considered across the globe. The criteria are as follows:

- Based on numbers of people, as each people takes some amount of fresh air. Normally it is varied from 2.5 l/s (liter per second) to 10 l/s and it depends on the type of work they are performing. For example, if there are 5 people working in office, fresh air = 5 x 10 l/s=50 l/s

- Based on air changes per hour, different value for different types of rooms. Suppose, if the room volume is (5 x 4 x 3) 60 m3 & ACPH is 0.5, then fresh air quantity = 60 x 0.5 = 30 l/s

- Leakages, as during the operation air will be leaked and the same needs to be backed up by fresh air. Let’s consider the leakage is calculated as 15 l/s

- Air quantity requirement for heat loads, this is applicable for the rooms where 100% supply air is exhausted.

Now, we have got the three values,

- Nos of people = 50 l/s

- ACPH = 30 l/s

- Leakage = 15 l/s

Hence, fresh air quantity or ventilation air quantity is the maximum value of the above, i.e., 50 l/s

Where 100% Ventilation System is Considered in AC system?

There are many rooms where conditioned air is supplied but 100% of that supply air is exhausted to the atmosphere. Let’s what are the areas under this condition?

- Battery Room: Here, H2 gas is generated by the batteries. So, this air should not be recirculated by any means. So, 100% ventilation system is considered. Now a days, very low emissive battery is used in many areas and it can be recirculated if it is unmanned. However, a proper safety measure has to be taken.

- Chemical Room: There are many areas where chemical rooms need to be air conditioned. In this case, conditioned air should not be recirculated due to hazardous chemicals. Hence, 100% ventilation is to be provided.

- Pantry/Dining/Shower/Toilet: 100% ventilation is required to remove contaminants or odor.

Ventilation System Special Requirements

The hazardous area study is the most critical part of ventilation system selection.

- If it is hazardous area, then equipment should be selected based on that requirements.

- For example, pump house is normally safe area, hence, no need to consider a special protection. However, if we try to ventilate a battery room, it should be considered based on hazardous area classification.

- Most of battery room are classified as Zone-1. The motor of battery room fans are explosion proof. Ducts are made of stainless steel

Conclusion

From the above article, we conclude that ventilation is the foremost step in maintaining the thermal comfort, healthy and fresh air quality at the indoor of a building and making the building to be more sustainable. In this modern world, the outdoor air quality is worsening day by day, and to prevent it from entering our homes it is necessary to build a good ventilation system that can lead to good health.

In numerous types of ventilation discussed above, each specific type has a particular principle of work. These above-mentioned different ventilation systems should be looked upon by civil and mechanical engineers before constructing any structures since they can reduce energy consumption on a great scale and are useful and essential to ensure an adequate amount of airflow for good ventilation.