Let’s start the article about Piston Rings! We have captured all about the piston ring in terms of definition, types, applications, installations, etc. It is quite evident that every tiny part of any machinery holds massive importance? Sometimes people emphasize size and weight to deduce the functioning, but in complicated machinery, every single part counts whether it is big or small.

- When it comes to one of the most scintillating and useful inventions by mankind, the engine gains the top spot.

- The engine is massive machinery that has numerous parts.

- The piston in the engine is a vital part that is used for the core functioning or strokes.

- One of the delicate yet useful parts of a piston is the piston rings.

What are Piston Rings?

Piston Rings Basic

Here we are delving with piston rings, and it’s comprehensive information that will be very useful for those interested in automobiles. This excerpt will not only provide a holistic view of piston rings but also help out in installing as well as troubleshooting.

Brace yourself for the vital information of an efficient and delicate part of the piston.

Before getting into piston rings, it is very important to get an overview of the piston where it is attached.

Basic Knowledge of Piston

A piston is a part of the engine that helps in the combustion process. It is a cylindrical shape component that slides forth and back in the cylinder bore with force generated in the combustion chamber.

- These are mainly manufactured of cast aluminum alloy.

- The main reason for using this alloy is to get much-needed thermal conductivity with lightweight properties.

- This property helps the material to conduct as well as transfer heat effectively.

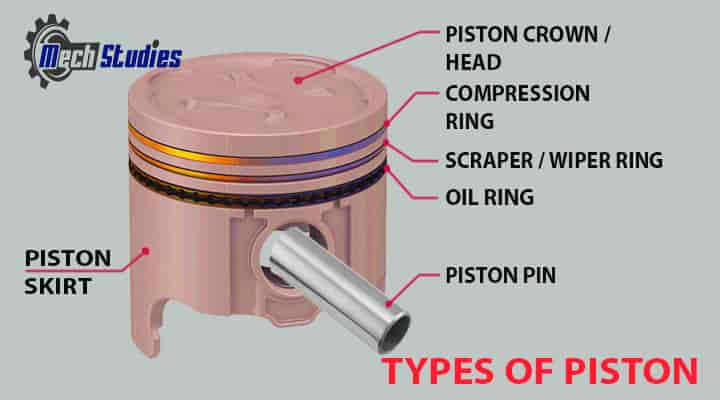

The piston’s basic parts are the piston head, piston pin bore, piston pin, skirt, ring grooves, ring lands, and piston rings. The piston head is the most critical part of a piston as it has to withstand par-level heat and forces during the engine’s operation.

One of the parts of this piston head is a piston ring. Further analysis of the piston ring is mentioned below.

Piston Ring Definition

A piston ring is a split ring used to get a proper seal between the cylinder wall and the piston. The main properties that these rings need are to be in their original shape while withstanding – ,

- massive load,

- heat, and

- dynamic forces.

These attributes can only be gained by using metal for its manufacturing capable of providing all these.

Commonly piston rings are made up of cast iron.

Functions of Piston Rings

The functions of these rings are vital as they provide different attributes to the piston head. Here are some of the functions of this piston ring:

- These are used for maintaining the gas compression between the cylinder wall and the piston.

- It is crucial to ensure that the ignition doesn’t leak into the opening due to the cylinder and piston’s action.

- This is the main function of a piston ring that helps prevent the leak, which in turn helps in providing sufficient power.

- Piston rings are the parts that help in providing minimum lubricating oil film that prevents scuffing due to the repeated ignition process.

- While the ignition takes place at a thousand times per minute, the adjustment through providing a small amount of oil takes place due to this part.

- The main function of piston rings is to transfer heat to the cylinder from the piston head. Due to the gas ignition, the temperature is on the rise and ultimately reaches 300 degrees.

- This is lethal as it can damage the engine; the piston rings help release this heat effectively.

- Preventing the most lethal knocking process, with the help of a piston ring, one can easily prevent the piston from getting knocked on the cylinder wall.

- This also prevents engine failure and provides smooth functioning.

These functions are useful, but it is imperative to get piston rings to understand the core functionalities.

XPH is your home for BMW, Audi, Ford Mustang, VW, Porsche and Nissan GTR aftermarket parts.

Types of piston rings

Three different types of piston rings are responsible for different functions. Following is the brief description that can help you out to understand the same:

- Compression Ring

- Wiper Ring

- Oil Ring

Let’s try to understand all types of piston rings,

Compression Ring

The compression ring is the type of piston ring, which is the closest one to the combustion gases. It also withstands massive operating temperature as well as chemical corrosion. The compression rings can transfer almost all the heat in the combustion chamber to the piston’s cylinder wall.

- Most of the engines used taper-faced or barrel-faced compression rings.

- The barrel-faced compression rings are the piston ring capable of providing throughout lubrication to the cylinder wall and a piston.

- The taper-faced compression rings are responsible for providing a wiping action that prevents the excess oil from reaching the combustion chamber.

Wiper Ring

This ring is used for providing an optimal and consistent thickness of the oil film that helps to lubricate the exposed path of the compression ring. It is also called a backup compression ring, Napier ring, or scraper ring.

- The shape of the wiper ring used in engines is of taper angle face positioned towards the oil reservoir.

- This ring’s core function is to provide wiping action to the piston while it moves towards the crankshaft.

Oil Ring

These rings are one piece entity that is equipped with two extremely thin running surfaces or rails. The oil rings are situated on each side of the expander.

- The engines use a three-piece oil ring that is equipped with an expander and two rails.

- With this, the piston gets increased pressure applied on the cylinder wall.

- With the proper knowledge of different types of piston rings, it’s time to delve into some of the design considerations that help get all the efficient functionalities.

Spring is here! Save big on our best-selling WAGNER TUNING BMW F CHASSIS N55 CATTED DOWNPIPE

Design Considerations for Piston Rings

While getting all-around information about piston rings, it is very important to delve into these piston rings’ design considerations. There are some of the attributes that should be considered while designing.

Inherent pressure

A piston ring helps in sealing the combustion chamber with the help of inherent pressure.

- It is the internal spring force that helps in the expansion of the piston ring.

- It is one of the most important considerations that should be followed in piston rings’ design considerations.

Radial fit

- The radial fit is one of the prevalent and efficient attributes that should be considered.

- The radial fit has useful functionalities as it provides an efficient seal.

Applied pressure

Applied pressure should be considered as it is closely related to the inherent pressure. Applied pressure is the pressure that comes into play when expansion takes place in the engine. Considering this applied pressure in the design aspect makes it quite useful.

Contact pressure

One of the foremost design considerations of piston rings is the contact pressure. This pressure is simply dependent upon different attributes such as exposure to combustion gases, piston ring material, and free piston ring gap.

- The material used in manufacturing these piston rings is cast iron, which is equipped with optimal attributes.

- The design considerations are useful when we select an effective piston ring as per the need.

Mainly the above attributes are needed by Briggs and Stratton engines, which are among the simple types.

Core Working of Piston Rings

As we have discussed, different kinds of piston rings are available in a piston at designated points that perform specific tasks.

- The piston’s top is equipped with a compression ring, which provides sealing to any kind of leakage inside the combustion chamber while the combustion process goes on.

- When the air-fuel mixture’s ignition takes place, then the pressure from combustion gases shifts to the piston head, which makes it move towards the crankshaft.

Check a NICE VIDEO from Engineering Explained

The second one is the wiper rings present above the oil rings and below the compression rings.

- The construction of these rings is the somehow tapered face.

- It also helps in sealing the combustion chamber.

- These are mainly used for wiping the liner wall to clean the impurities and excess of oil.

- This helps in the overall effective functioning of the piston.

Last but not least, the piston ring that is located at the bottom groove is known as an oil rig.

- This piston ring’s foremost function is to get rid of excess oil from the walls of the cylinder.

- This is a mandatory function that helps efficient piston working.

- These oil rigs are also equipped with a spring that provides the extra push to the liner, which helps in wiping.

Steps for Installation of Piston Rings

The below-mentioned steps will help you to understand the core process through which these piston rings are installed on the piston head.

- The foremost step is to check whether the rings are of the same grade or not. It is vital to get all-around attributes of the piston ring to fit it in the right place.

- You can also check the manual that helps in placing it in its exact groove.

- The groove where these rings are going to be fitted should be cleaned thoroughly. Ensure that there should not be any sludge or carbon deposit.

- While cleaning, keep a check on the particular protection film available on the piston grooves; these should not be damaged at any cost. Prevent the use of grinding or chipping tools.

- After the cleaning, the piston ring should be installed with the help of a special tool that expands the ring. It helps in inserting the ring in the groove easily but sliding down from the piston head.

- There is a specific identification that shows the top of the piston rings that helps incorrect fitting.

- Piston ring installation guide

is elaborated in an article.

is elaborated in an article.

Special Note

It is recommended to use a ring expander tool as it inappropriately can cause damage to the ring. In addition to that, there may be some lethal issues such as accidents as it provides regular tension.

In case the tool is not available, one can use the rags or cloth pieces that help expand the rings effectively.

In addition to this, after installing all the rings, keep a check on the opening of all the piston rings. If these were not aligned, then the possibility of gas leakage persists.

Reasons for Piston Rings Failure

While getting a holistic view of piston rings, it is essential to get an idea about the reasons for piston rings’ failure. Here are some of them:

Excessive pressure

Due to the piston rings’ excessive pressure as the combustion chamber exerts hefty amounts, then the performance of the ring gets appalled.

Pinging and detonation of the fuel are the primary causes that lead to the failure of piston rings.

Contaminated fuel

Wearing down of piston rings takes place when there is inappropriate or contaminated fuel oil. This causes the apparent loss of sealing the combustion gases.

Apart from this, cylinder oil quality, wrong duel timing, flawed combustion process, and worn liner also cause the worn-out piston rings.

The sign for a worn piston ring is the blowby action, i.e., the gas passing under the piston.

Sludge and carbon deposit

The sludge and carbon deposit is also the cause of cracking or breaking of the ring, which is also a significant cause of piston rings worn out.

Intake of excessive oil

When the intake of oil increases substantially, it shows the damage of piston rings.

It can be identified when there is thick smoke coming from the exhaust. It is because of the oil being guzzled up.

Poor Performance

When the overall performance gets deteriorated, it is an effective sign that your piston rings need to be replaced.

The loss of engine power is the result of a damaged piston ring.

Optimal life

As we know that every machine part has a specific lifecycle, the piston ring also has its particular time limit for replacement and overhaul. A piston ring’s life depends on different factors such as the size of the engine, piston ring type, and the operational condition of the rings.

- Specifically, the ring’s overall life for a large two-stroke piston ring can be up to 24000 hours.

- For smaller engines, it can be up to 15000 hours.

- In heavy machinery or automobiles which use 4-stroke engines is approximately 6000-8000 hours.

- After these specific limits, it is recommended to change the piston rings.

Common Myths Regarding Piston Ring

If you have proper knowledge of these delicate parts, then it can be beneficial, but if something lacks then, it may cause problems. This occurs due to the hoax and myths regarding piston rings.

Here we are also providing some of the myths and the exact fact about that:

Myth: It can be stored in any way

People often think that this piston ring is rugged and can be stored in any way. If you are keeping it without any safety, it may cause a reduction in quality and mishappenings.

The recommended way to keep these piston rings is in a protective layer of oil that helps prevent corrosion and rust.

Myth: It doesn’t need any maintenance

It is a common myth that piston rings can withstand for a long time without any maintenance. It is recommended to perform the due maintenance when the engine performance deteriorates.

The piston’s maintenance is quite simple as it doesn’t need specific methods; just some precautions can provide maximum life.

High Rated Automotive Engineering Course

Automotive 101: A Beginners Guide To Automotive Repair

Automotive Engineering: Automobile Fundamentals and Advanced

Automotive Engineering; Hybrid Electric Vehicles

Do it Yourself – Automotive Electrical Diagnosis – Beginner

Do it Yourself-Automotive Electrical Diagnosis-Intermediate

Automotive Engineering; Common Rail Direct Injection(CRDI)

Fundamentals of Internal Combustion Engines – IC Engines

Hybrid and Electric Vehicle for Beginners FULL Course 2021

Automobile Safety: Understanding Car Crashes for beginners

Hybrid Vehicles The Fundamentals & Operating Principles

Conclusion

Piston ring has numerous usages. The primary function of these rings is to seal combustion chambers in diesel engines. This excerpt is all about piston ring holistic knowledge with their working, installation, and design considerations.

In addition to the standard information, the reason for piston ring damage will help you address the problems. It also helps in the proper installation of the piston rings.

While this information is ample, we can delve more into this topic.

Our Videos

Refer YouTube

Our Apps

Check out our ‘MechStudies – The Learning App’ in iOS

& Android

Check out our most viewed articles,

Reference Articles

It’s great that you mentioned how the functions of piston rings are vital as they provide different attributes to the piston head. I was reading a technical book earlier and I learned a little bit about how pistons operate. According to what I’ve read, it seems there are piston rings for servo motors now too.

https://adpistonring.com/servo-motor-piston-rings.html