In this article, we will learn about the screw water pumps, along with its basic definition, various parts, working principle, types like single, twin, triple, etc. screw pump, applications.

Let’s explore!

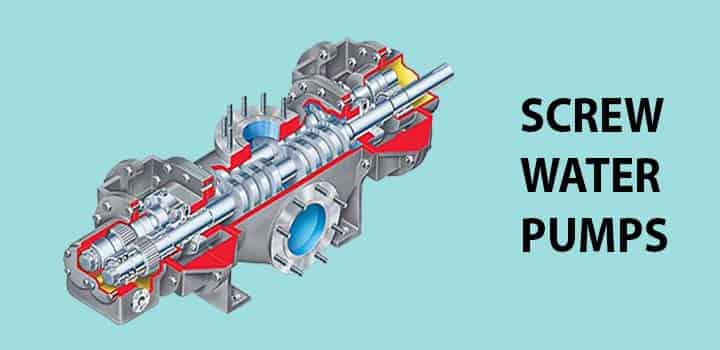

What are Screw Water Pumps?

A Screw Pump is a type of rotary pump and a mechanical device also called a Water Screw (3-Screw Pump).

A screw pump is a positive displacement pump that uses one or several meshing screws or rotors to and rotate within a cylindrical cavity or liner and increase the pressure of oil or hydraulic fluid to get it to transfer from one point to another.

- The best example of Screw pumps is the Archimedes screw pump that is still useful in irrigation and agricultural applications.

- It is used to transport various fluids such as viscous fluids, fuel, injection oil, lubricating oil, etc.

In this article, we shall get to know the Screw Pump system, its working, applications, advantages disadvantages, and many more, so let’s begin!

Parts of Screw Water Pumps

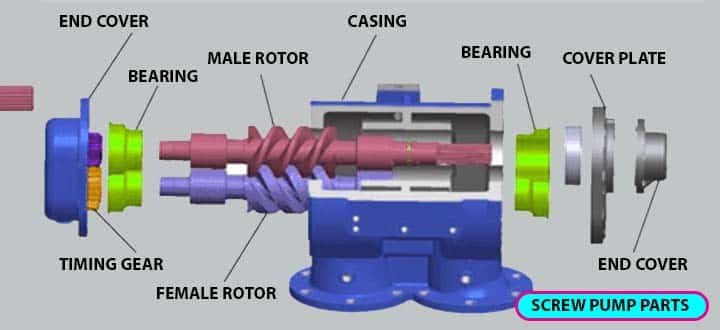

The main structural components of screw pumps are the drive gear motor, the adapter stand, the stator-rotor pair, the outlet discharge pipe, the chamber, the hinge, the shaft sealing device.

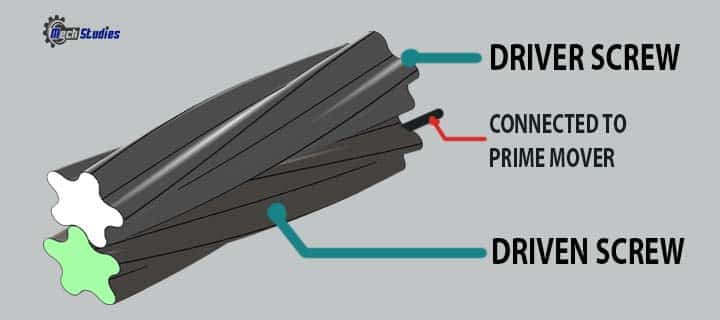

The key components of a screw pump are the driven screw and the driver screw. A general screw pump design consists of the following parts:

Driver Screw (Male Rotor)

A driver screw is one of the rotating parts of the screw pump. It helps in pumping the fluid at the constant volumetric level at any location.

- The main role of a driver screw is to drive the driven screw through a timing gear.

- A driver screw is made up of high tensile steel.

Driven Screw (Female Rotor)

A driven screw rotates along its axis through the transmitted motion by a timing gear.

- It rotates in the opposite direction unlike the driver screw with a fixed clearance area.

- Since both the driver and the driven screw do not have a change in the clearance area and they rotate in opposite directions it moves the fluid along the rotating angle to give non-pulsating output.

- It is also made up of high tensile steel.

Timing Gear

The driver and the driven screws when running have a very fine clearance area so there is always a chance of contact. If this is not looked upon it might lead to some unexpected situations.

- Thus timing gear is installed on a screw pump to verify such kinds of events.

- The timing gear fundamentally drives the driven gear in such a way that there isn’t any chance for the metal-to-metal contact between the male and the female rotor assembly.

Suction and Discharge Ports

To avoid the pump from becoming dry the suction and discharge ports provide starting liquid medium to the screw pump.

Bearings

There are usually two kinds of bearings, the bearings which are subjected to heavy loads together with axial and radial forces during pumping operation are called upper bearings and the bearings which are subjected to minimal load with a crucial task to maintain the alignment of the pump components are called as lower bearings.

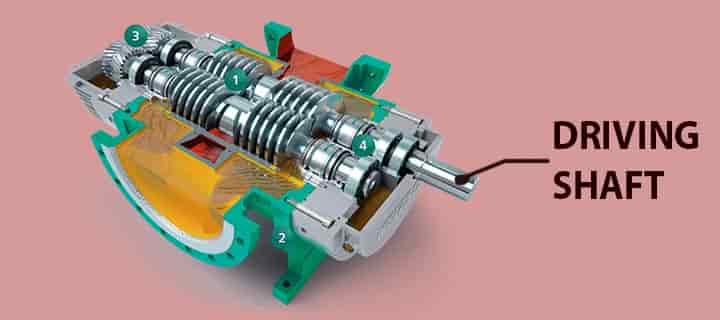

Driving Shaft

It is a component of the pump that connects the pump assembly to its driving motor using a proper set of adaptive couplings.

- A driving shaft is an integral part of the pump.

- On most pumps, the driving shafts are made up of mild steel that connects the driving screw to the motor operation.

How Does Screw Pumps Work?

A screw pump is a type of positive displacement pump which initiates pressure by putting axial acceleration within its clearance area to the fluid medium.

In terms of operating elements impacts, they are distinguished as volumetric pumps.

Screw pumps may comprise stationary screws with a rotating screw or screws like gear pumps. The geometries of these screws may differ.

Step#1

- In Screw Pumps both the driver and the driven screws using timing gear rotate in phase while in gear pump one gear drives the other.

- The screws are covered inside of a liner which is typically made up of some variety of metal.

Step#2

- The fluid runs into the screw cavities within this liner and as the screws rotate and intermesh the fluid is enforced throughout the pump and out of the discharge.

Step#3

- It is feasible for any fluid that is pumped into the cavities to slide back from the pump to a low-pressure zone and because of this there has to be some separation between the liner and the screws.

- This volumetric slippage is normally not an issue for high viscosity fluids but as the viscosity decreases this slippage becomes considerable thus minimizing the effectiveness of the pump.

- This volumetric slippage factor and clearances should be looked upon when pumping water or similar fluid where vapor slugs are assorted into the fluid stream to shorten the slip.

Step#4

- The screws can intermesh closely with almost less clearance when the pump is pumping some type of viscous fluid or oil as it also lubricates the surface when pumping the fluid.

- When pumping water or gas mixture or some other light fluid, rapid wear will occur as these parts cannot contact each other. For this, a three-screw pump should not be used for water or multi-phase service.

Shaft seals are only needed on the driving rotor in case of a triple screw pump, the other rotors together with bearings are enclosed inside the pumping chamber and do not jut out.

In the case of a two-screw pump or a four-screw pump, it’s a complete opposite case where both the rotors stick out through the pump case, because of this four shaft seals are needed in a screw pump which have two rotors.

Types of Screw Pumps

Screw Pumps are available in various designs and types but they all operate in a similar manner that is as follows:

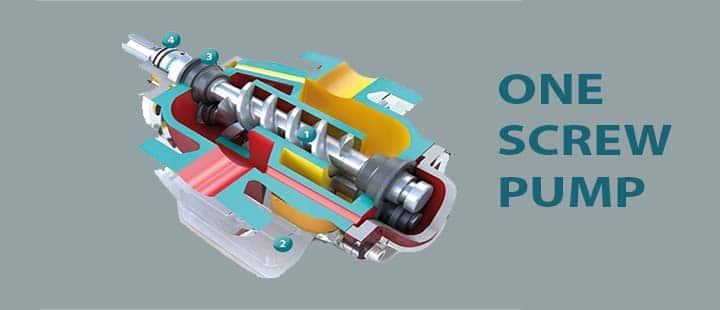

Single or One Screw Pump

Single Screw Pumps are coming under rotary Positive Displacement Pumps and works based on the principle of positive displacement. It is widely used for the smooth and non-pulsating flow. Single screw pump means as the name suggests, only one screw is used.

- Very efficient to handle abrasive liquids.

- Very efficient to handle non-abrasive liquids as well.

- In case fluid consists solid particles, these pumps are best to use.

- One screw pump or single screw pump is reversible and non-clogging type.

- High suction capacity

These pumps comprise one helix metal rotor and a double helix stator.

Let’s see how this pump works? The rotor is connected to a prime mover and when the motor starts, the rotor will also start to rotate. Due to the rotation of the helix, cavities will be created and the fluid will move along the cavities by the principle of positive displacement. Hence, pressurized fluid will come out from the discharge port and the pump will work.

Properties of Single screw pumps are,

- Single Screw Pump is also called Progressive Pumps (PC Pumps) or Worm Pumps.

- Since the rotor used in these pumps have a twisted round shaft and is not in the form of typical screws so they basically are not considered in the Screw Pump family.

- A progressive pump has a rubber lining in the pumping chamber.

- It has only a shaft that is moderately twisted in the shape of a screw.

Single screw pumps are used in the following industries,

- Chemical industries

- Paper industries

- Waste water treatment (sludge handling or sewerage handling)

- Oil & gas

- Painting

- Food industries (transferring ketchup or sauces, jelly, yeast, etc.)

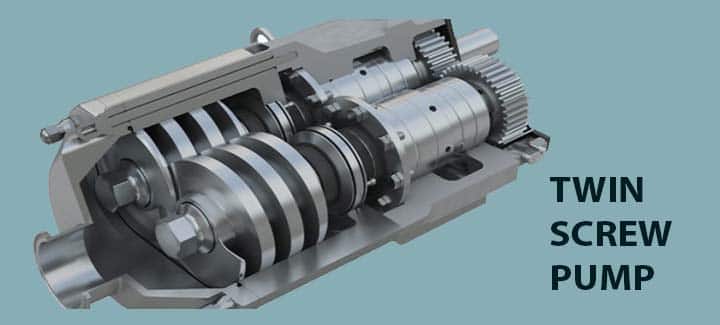

Twin or Two Screw Pump

Twin-screw pumps or two screw pumps means, as the name suggests, two nos. of the screw in the casing. It works based on the principle of positive displacement.

Twin-screw pumps are widely used for abrasive or non-abrasive fluids or any type of non-homogeneous fluids.

Let’s see how twin-screw pumps work? It has two rotors, driver & driving rotors. Driver rotor is connected to a prime mover and when the motor starts, the rotor will also start to rotate. During rotation, the cavities are formed between two screws and moves from the suction side to the discharge side.

- Two screw pumps are also called Twin Screw Pumps and have a single suction design.

- Two screw pump is the most used in high power applications such as heavy oil pipeline transfer.

- In a Two screw pump, one screw drives power from the sources such as engine or motor, and the timing gears are normally integrated to rotate the second screw.

- This pump can work easily in dry conditions as sufficient clearance between rotors and rotor to casing.

- It can give good performance at low NPSH like 1-1.6 meter.

- It is reversible

- Pulsation and noise level is low

- Can work with high viscosity

- Self-priming pump

- It can work without any speed reduction gears.

- This pump gives constant flow even the pressure is changed.

Twin-screw pumps are used in the following industries,

- Seawater handling

- Chemical handling

- Waste water treatment (sludge, sewerage handling)

- Oil & gas industries

- Marine application

- Food industries

- Pharma industries

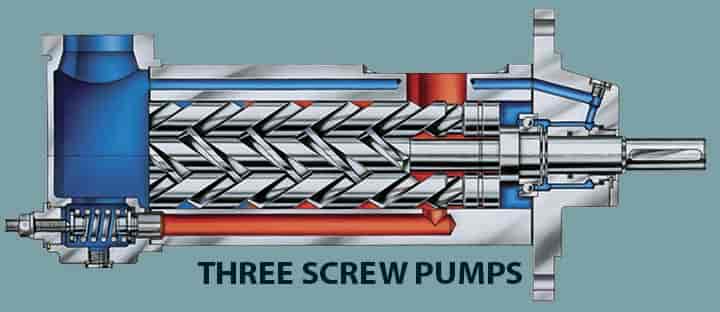

Triple or Three Screw Pump

Three Screw Pumps are also known as Triple Screw Pumps. Triple or Three-screw pumps, as the name suggests, have three screws and works based on the positive displacement principle. It consists of three screws,

- One Driver screw (which is connected to prime mover)

- Two driven rotors, mounted as opposed idlers rotors

- Three Screw Pumps are generally used for smaller applications such as lubrication systems, oil burners, fuel injection, boosting, etc.

- In a Three screw pump, one screw drives power from the sources such as engine or motor, and then with the use of timing gears rotate the other two screws which are around it.

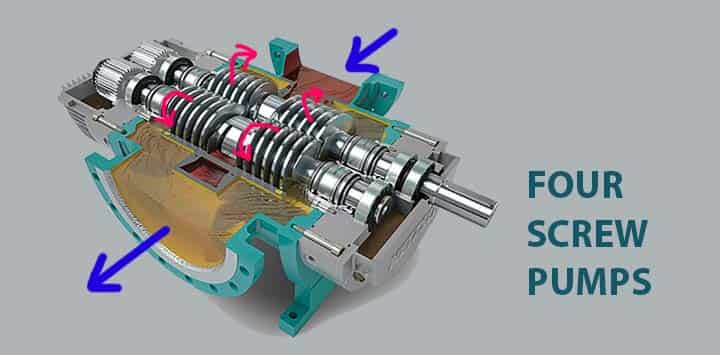

Four Screw Pump

The Four Screw pump works the same as a twin-screw pump but has two screws per rotor each facing opposite directions and have a double suction design.

- The pump then sucks fluid in the suction port, splitting it equally, and is scattered to both ends of the pump. The two fluids rush through the pump towards the middle and unite together before leaving the discharge port.

- The Four screw pump has timing gears to drive the second rotor like the twin-screw pump. Four Screw pumps are frequently used in Multi-phase applications and oil transfer pipelines.

Five Screw Pump

The Five Screw pump works almost the same as a three-screw pump or triple screw pump but has five screws instead of three.

- The Five Screw pump has one driving rotor that drives all the other screws.

- They are frequently used in lube-oil or hydraulic applications.

Where Screw Pumps should be Used?

A screw pump can be practically used in any fluid medium but there are circumstances where it is more beneficial than other pumps.

- The best-fitting application for a screw pump is where we need non-pulsating constant output and having trapped air or gas as the medium and having high viscous fluid and having low NPSH with the potential to oppose dry run for a short run interval.

- When there is varying back pressure and we require constant output flow then a screw pump is the best choice. They are also an ideal choice for the regeneration of larger cyropumps.

- Even at a high RPM and output pressure, a screw pump is popular for its noise-free operation. It is a very adaptable machine which supplies the advantage of high volumetric efficiency and low running cost of the operation.

- In food processing, food drying, and food packaging, oil-free screw pumps are used to keep away the contamination of pump oil by water or any other debris.

- Screw pumps also provide fewer vibrations, lesser maintenance, less shear and axial forces, controlled output, with the benefit of zero emulsification even when the fluid has some traces of water.

Applications of Screw Pump

Screw pumps are the oldest type of pumps and have become the standard solution and have many uses in numerous different industries such as Manufacturing, Mining, and Oil and Gas.

Almost all the applications of the screw pumps manage with high viscosity fluid (oil or asphalt) or Multi-phase liquid meaning in the fluid stream there is a mixture of liquid and vapor mixed together.

Let us see some examples below:

- Hydraulic and Lubrication Systems: Different lubrication systems and hydraulic systems use a screw pump which is usually a triple screw pump. Lubrication systems like this are used for providing lube oil for large machinery and supplying hydraulic power to High-pressure Hydraulic systems or handling elevators in buildings.

- Heavy oil Pipeline: Screw pumps can offer a perfect solution for pumping and moving high viscosity fluids like oil through pipelines. Screw pumps are often used in applications where they can pump higher viscosities than a centrifugal pump and can pump higher flows than a reciprocating pump. In such cases sometimes large pumps are used to get the desired flow rate which is usually driven by large diesel motors or electric motors.

- Multi-Phase Pumping: Multi-phase pumping is a mixture of fluid and vapor together and is also known to be one of the most challenging pumping applications. Major damage can happen to compressors when liquid enters, same as serious damage occurs to most pumps when air enters. A screw pump can be a hybrid between a pump and a screw compressor when built correctly able to handle both liquid and gas. Depending on the size of the liquid boot vessel, a multi-phase pump can pump 100% vapor for a few minutes.

- Screw pumps are also used in wastewater treatment, the tobacco industry, textile and paper industry, metalworking, food industry, and chemical industry.

Advantages of Screw Pumps

The main advantages are, as follows

- Screw pumps have high robustness and low mechanical vibration.

- They have a very high tolerance against water vapor and particles and have very low internal velocities.

- Screw pumps have very high pumping speeds.

- In screw pumps, the Medium being pumped is not contaminated.

- Wear and tear of the rotor are eliminated.

- Due to internal compression, screw pumps are highly efficient.

- The maintenance and operational costs are very less.

Disadvantages of Screw Pumps

The main disadvantages are, as follows

- Screw pump is relatively expensive and very hard to maintain.

- Screw pump requires a gas ballast to pump light gasses such as Helium and hydrogen.

- Without a gas ballast, screw pump has a worse ultimate pressure and lower pumping speed for light gases.

- Screw pump cannot be lower down to small pumping speeds below 50.

High Rated Course

Centrifugal compressors: Principles, Operation and design

Reciprocating Compressors: Principles, Operation & Design

Understand & Predict Your Centrifugal Compressor Performance

Conclusion

Over the years, pumping technology has developed as per technological advancement and screw pump is considered as one of the most favorable technologies in this industry.

The Screw pump has numerous important advantages like being more versatile, reliable, and efficient as given in the above article. To get the right type of pump it is necessary to have a thorough knowledge of the characteristic curves of all types of pumps.

From the above article, we conclude that different types of screw pumps are an important option for transporting a wide range of fluids, including high-viscosity crude oil, and perhaps the most major point in today’s global climate for screw pumps is their cost-saving edge.

Refer to our most viewed articles,

Reference Articles