A slotter machine is basically a reciprocating machine that is used to produce flat surfaces, flat slots, contour surfaces, contour slots, splines, internal grooves, etc. In this machine, there is a ram that holds a slotting tool and reciprocates the tools vertically up and down. During the downstroke, the cutting tool acts on the surfaces. In this chapter, we will learn all the details about the slotting machine!

What is Slotter Machine?

Slotter Machine Definition

Slotter machine is the machine, which is used to make different kinds of surfaces, slots, splines, grooves, etc. by the vertical reciprocating motion of the cutting tools.

- In this machine, the cutting tool removes unwanted metals

- During the vertical motion, cutting is done in downstroke and upward stroke is simply idle.

- Due to the vertical action, this machine is known as a vertical shaper machine.

- It helps to machine the internal components.

- The cutting tool is normally made of HSS that is High-Speed Steel.

The Slotter machine is almost similar to the shaper machine, except the moment of the ram. Ram in the shaper machine, moves in the horizontal direction, and in the slotter machine, the ram reciprocates vertically.

Functions of Slotting Machine

The main function of a slotting machine is to make the workpiece into the required size and shape by removing metal chips.

History of Slotting Machine

The slotter machine is invented by BRUNEL.

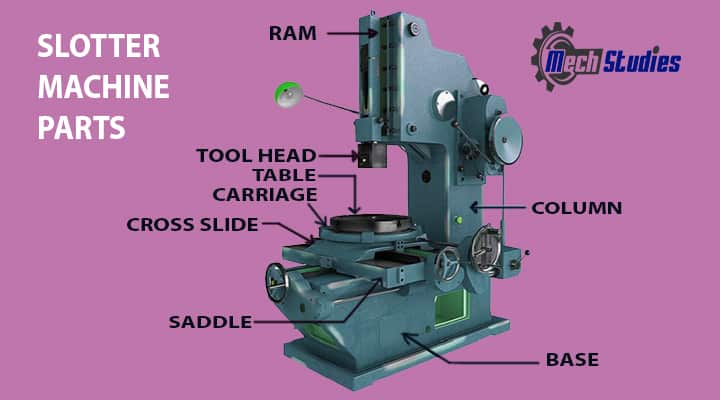

Slotter Machine Parts

A slotter machine has the following parts

There are many components in the slotter machine. These are as follows,

- Bed or Base

- Column

- Saddle

- Cross-slide

- Handwheel

- Carriage

- Rotating or Circular table

- Ram

- Tool head

- Feed drive

- Ram drive

Check the main parts of a typical slotter machine,

Description of Slotter Machine Parts

Would you like to know the basic details of each part of the slotter machine? Let’s explore!

Bed or base

The bed or base is the main foundation of the slotter machine. It takes entire machine loads as well as cutting forces and supports all other parts in the slotter machine.

- The base or bed is very rigid to take all loads

- The bed takes all dynamic loads, cutting forces, impact loads.

- The bed is provided with guideways so that other part ‘saddle’ can mount easily

- The bed as well as guideways are perpendicular to the face of the column.

- The Slotter machine is made of Cast Iron.

- It supports other parts like a table, ram, column, etc.

- It has good strength

- It has good vibration absorption capability,

Carriage

There is a carriage above the bed. It carries all the parts related to the tables. It carries

- saddle,

- cross-slide,

- rotary table

Saddle

The saddle is another important part of the slotter machine. It is always mounted on the bed by the smooth guideways. This saddle can be easily moved towards the column or away from the column, which means it helps to give longitudinal movement to the table, as the table is mounted on the saddle.

- The movement of the saddle can be manual or by power-driven.

- It helps to give longitudinal movement to the table

- The top portion of the saddle is properly finished

- He finished portion of the saddle is having guideways

- Another part named cross-slide is mounted on the guideways.

- Saddle guideways are perpendicular base guideways.

Cross slides

We have already seen that saddle’s top face is having guideways. Now, the cross-slide, another part of the slotter machine, mounted on that guideways.

- The cross slide is mounted in such a way, that it can be moved parallel to the column’s face.

- It holds the table

- It is used to move the table in cross direction to the saddle movement.

- It can be operated in a manual method or can also be driven automatically.

- There is a circular table, and it is mounted on the cross slide.

- It can move in a forward or backward direction.

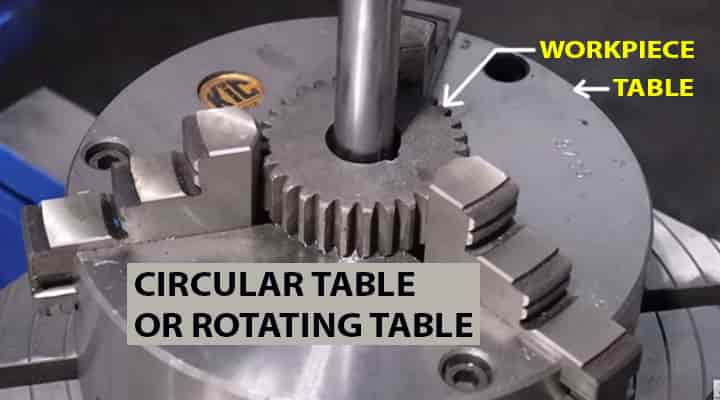

Circular table or Rotating Table

A circular table or rotating table is used to hold the workpiece. This table is also rigid and it is normally made of cast iron.

This table is the rotary type and round shaped and placed on the cross-slide.

- The table holds the workpiece by clamping, or by fixtures.

- The table is attached with a worm and this worm is connected with gear arrangement.

- The table can rotate on a cross slide based on a worm arrangement.

- It can rotate to circular feeding to the work.

- This rotation helps to feed the workpiece properly.

- It can be adjusted in the directions like crosswise or longitude.

- Rotary feeding can be given by power or manual.

- The table can be graduated in degrees.

- The table has T-slots by which it can firmly hold the workpieces.

Column

The Slotter machine is having a very rigid column and it’s basically a vertical column. This column mainly contains the driving mechanism and feed mechanism.

- The column is placed on the base.

- It is a column of boxed shape.

- The column consists of a driving mechanism

- It houses one of the main parts, ram.

- The column is having smooth vertical guideways.

- Ram reciprocates vertically through the smooth guideways due to the driving mechanism.

- Feed mechanism means the mechanism of table, saddle, cross slide.

- The column provides support to drive and feed mechanism.

- Colum is very rigid and normally made of cast iron

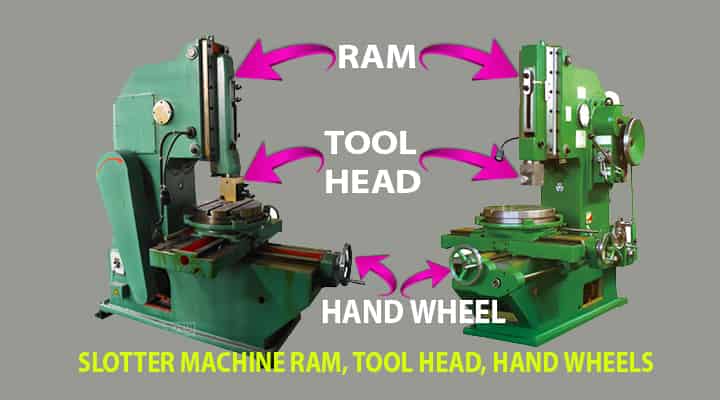

Ram

Ram is the most vital component in the slotter machine. The face of the column has guideways. This ram reciprocates on the guideways in a downward and upward direction.

- Ram consists of smooth slots to move upwards and downwards

- Ram produces force from its reciprocating motions.

- During the downward stroke of the ram, cutting happens.

- On the other end, no cutting in the upward stroke.

- A tool head is attached at the lower end of the ram.

Tool Head

In the slotter machine, the cutting tool has to hold firmly for the operation. This tool head acts as a holder of the cutting tools.

- Normally, tool holder holds a single-point cutting tool.

- Different kinds of cutting tools can be used based on the cutting requirements.

- In a few modern machines, tool holders are different with respect to the conventional tool holders and it releases heat during upward stroke.

Hand Wheels

There are handwheels to support the different kinds of movements, rotations to adjust the workpiece.

Guide Ways

We have already discussed that there are guideways in many parts for smooth operation and movement.

- Guideways are on the base

- Guideways are on the saddle

- Guideways are on the cross saddle

- Guideways are on the column

Cutting Tool

The cutting tool is the main part to cut the workpiece. It cuts and removes unwanted metals parts.

- Generally, in slotter machine, a single point cutting tool is used.

- High-speed steel (HSS) is widely used as a cutting tool.

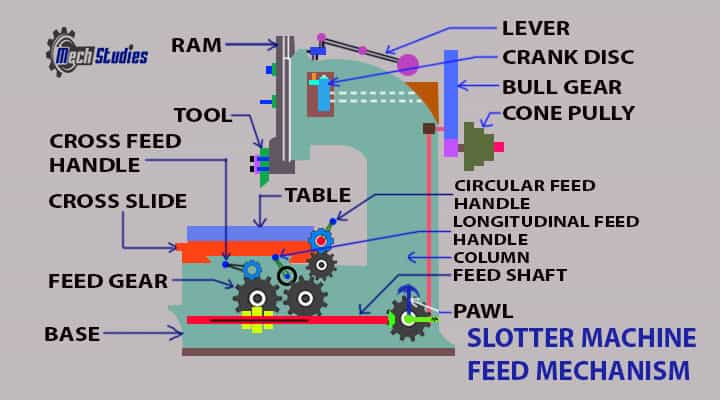

Feed & Drive Mechanism of Slotter

Feed Mechanism

The feed mechanism helps for the longitudinal movement and cross movements. During the operation, the workpiece to feed properly to get the proper shape. This feeding can be done by manual action or it can be power-driven too.

- It is able to provide circular feeding or rotary feeding of the table

- It can feed on the vertical axis.

- Intermittent feeding of the table is supplied at the beginning of each cutting or forward stroke of the ram. Kinematic System of Slotter Machine

- It is able to provide longitudinal movement to the saddle,

- It is able to provide cross-movement to the cross slide,

- It is able to provide circular and up and down movement to the table.

Ram Drive

The reciprocating motion of the ram can be created by different kinds of drivers. The main function of the drive is to give the motion but in addition to that, it helps to have slower speed during the downward stroke and faster speed during upward stroke. Return stroke should be quick since in this stroke no metal will be removed.

Due to the quick return in the return stroke, this mechanism is a known as quick return mechanism. There are normally three kinds of ram drive mechanisms are used in the slotter machine,

- Whitworth quick return mechanism.

- Variable speed motor drive mechanism.

- Hydraulic drive.

Whitworth Quick Return Mechanism: In this mechanism, there is bull gear (big gear) and it is mounted on a rigid and fixed hub. This mechanism is fixed at the machine rear side.

- The bull gear is rotated by a driving pinion

- The driving pinion is driven by a drive normally motor.

- The driving plate is mounted on the fixed hub of the main shaft.

- The main shaft eccentrically placed in comparison with the center of the bull gear.

- A crankpin is fixed on the bull gear.

Now, can you guess, how does this mechanism work? Let’s know the mechanism process,

- When the bull gear rotates, automatically the crankpin also rotates.

- The driving plate is having a slot

- Crankpin is placed within that slot.

- When the crankpin rotates, it will move through the slot of the driving plate.

- The driving plate is connected to the crank which is connected to the ram.

- The rotation of the crankpin transferred to the driving plate and the same is further transferred to ram

- Ram gets reciprocating motion.

Hydraulic Drive: Hydraulic drive mechanisms are used in many slotter machines to provide reciprocating motion to ram and to feed round table as well as workpiece.

- The hydraulic drive mechanism helps to provide instantaneous feed.

- The hydraulic drive is running in the oil and all the parts in the oil are well lubricated.

- Due to good lubrication, maintenance is easy.

- The production cost is less.

- This drive is fitted with a safety valve which acts as overload protection.

- This mechanism works as step-less speed, and due to step-less speed, it is more stable.

- In this machine, the cutting tool will not be associated with wear and tear loss since tool head is connected a oil tank.

- The hydraulic slotter machine is small in size.

- Easy installation

- Low noise level.

- Ram can make 0-10 deg. inclination.

Variable Speed Motor Drive: Variable speed motor drive means the drive by which we can adjust different speeds based on requirements. This arrangement is done by different gear arrangements in the gearbox.

- It is driven by a variable speed motor.

- Here, many gears are used in the gearbox and the shaft rotates with the help of an electrical motor.

Working Principle of Slotter Machine

Basic Concept

In the slotter machine, we will learn how a cutting tool is shaping workpiece, how cutting speed is controlled, what is depth of cut, how feeding is done etc. However, before going to the working principle, it is necessary to have a basic knowledge of

- cutting speed,

- depth of cut,

- feed etc.,

Cutting speed: Cutting speed means the speed of the cutting tool, at which the tool cuts the workpiece.

- Cutting speed should be proper to avert time loss.

- The cutting speed determines the time duration as well as the quality of finishes.

- Cutting speed is selected based on proper research as well as the manufacture’s recommendation.

- Cutting speed is expressed in Revolution per minute (RPM) or feet per minute (FPM).

Depth of cut: When the cutting tool operates, the workpiece started to lose metal chips and workpiece undergoes shaping or grooving etc.

This cutting creates depth in the workpiece and creates a machined surface. Now, the distance or the height difference between the machined surface and the unmachined surface is known as depth of cut.

- It is the simple depth which cuts by cutting tool

- It is expressed in millimeters (mm).

Feed: The feed means the distance that the tool travels 1 revolution of the parts.

How Does Slotter Machine Work?

Let’s learn the working principle of the slotter machine. In the slotting machine, the ram holds a cutting tool in a vertical position. When the ram moves, the attached cutting tool is also moved. In this way, the ram creates a cutting force which transmitted to the workpiece through the cutting tool. Check out a very interesting VIDEO by ANUNIVERSE on Slotter Machine,

The process is as follows,

Workpiece Ready

- Take the workpiece

- The table has T-Slots, with the help of t-slots or clamps, or vice or other fixing arrangements, the workpiece is fixed properly on the round table.

- Tool holder used to hold properly

Ready to Feed

- Once the workpiece, is fixed on the table, it should be fed based on requirements during operation.

- Needs to mark the workpiece, the portion to be cut. A marking block can be used.

- There is a mechanism by which we can adjust the saddle or cross slide or table.

- It can be done in both the options like manual or automatic.

- All the parts are properly linked to avert any kind of error.

Based on the saddle or cross slide’s movement, a round table can move in three different directions,

- longitudinal direction

- transverse direction

- rotary direction

Ready to Ram action

- Ram is connected to crank

- The crank is connected to the driving plate.

- The driving plate is having slots and connected to the crankpin

- Crankpin is attached to a bull gear.

- The driving plate is connected eccentrically to the crankpin of the bull gear.

- Bull gear is connected to a pinion which gets power from the drive.

- When pinion rotates, bull gear, crankpin as well as crank moves.

- Since the crank is connected to the ram, the ram also moves.

- If gear moves fast, the ram also moves fast.

- Due to the mechanism, the ram moves up and down.

- That means the ram gets reciprocating motion vertically.

Cutting tool ready

- Ram holds a tool head that attaches a cutting tool.

- The cutting tool is attached to the tool head, normally HSS is used

- Before staring, the length of the stroke to be adjusted.

- It cuts the workpiece in a downward stroke, upward stroke is idle.

- The basic working principle is the same as the shaper machine except for the cutting tool movement. In a shaper machine, the cutting tool cuts the workpiece horizontally and in the slotter machine, the cutting tool cuts the workpiece vertically.

- A slip gauge is used to measure the cutting area.

Power supply & Control

- Power supply to be provided to the machine, which means we have to switch ON the machine.

- During ON, the ram starts its vertical movement.

- Control systems are there in the case; all the movement needs to be automatically controlled.

- Old shaper machines are operated manually but now a day, automated machines are widely used in industries.

Slotter Machine Operations

There are various operations are performed, as follows,

- External and internal all kinds of surfaces are easily machined.

- Machining flat surfaces

- Machining cylindrical surfaces

- Machining contour surfaces

- Machining regular and irregular surfaces

- Machining rough surfaces

- Machining cam surfaces

- Making external and internal slots

- Making external and internal grooves

- Making external and internal keyways

- Making external and internal splines

- Making internal surfaces of different shapes.

- Internal and external gear teeth machining

- Machining operation of dies

- Machining operation of punches

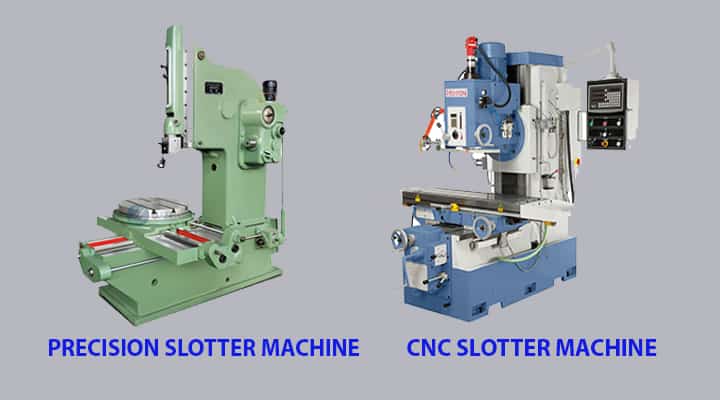

Types of Slotter Machine

Slotter Machines are classified into total four (4) categories,

- Punch Slotter

- Precision Toolroom slotter

- Production Slotter

- Special Purpose Slotter Machine

Let us learn the basics of all types of slotter machines.

Punch Slotter

Punch slotter is power operated very rigid, heavy-duty slotter machine used to remove metals chips to have required shape.

- It is used to remove large chunks of the number of metal chips.

- The length of stroke is high around 1800 – 2000 mm.

- Ram is driven by spiral pinion powered by variable speed reversible electric motor.

- The Feed is controlled by an electrical gear

- The length of the stroke is too large

Precision Toolroom Slotter

The precision tool slotter machine is comparatively lighter than the puncher machines. When the most accurate finish is required, precision tool slotters are best option.

- It has very good cutting speed.

- It is widely used to make special jigs

- It is used to produce a large number of productions

- It is used for light cuts

Production Slotter

Production slotter is used mainly for production work.

- In this machine, the ram swivels to 10 to 30 degrees.

- It is used for machining tapered jobs with the help of a ram swivel.

- Heavy-duty machine and made up of cast iron.

Special Purpose Slotter Machine

As the name implies, these kinds of machines are used for special purposes only.

- Mainly used for a high volume of production.

- It is comparatively cheap.

- It gives greater accuracy.

- Machining keys and gear hub etc. are wide applications in this kind of slotter machine.

Now a day, the slotter machine is upgraded with a CNC mechanism.

Slotter Machine Size

To specify the size of slotter machines, the following parameters are required to be known,

- Model no.

- Type of machine

- Stroke length (maximum) in mm

- Stroke length (minimum) in mm

- Rotary table diameter in mm

- Longitudinal movement in mm

- Cross movement in mm

- Speed of ram in RPM

- Speed ratio of work stroke and return stroke

- Number of feed

- Maximum table diameter in mm

- Ram adjustment in mm

- Throat depth in mm

- Distance from tool to the column in mm

- Type of drive

- Power Input in kW

- Motor rating in kW

- Table feed

- Floor space required

- kW of motor

- Total Weight, kg

Slotter Machine Applications

These are the applications of a Slotter Machine:

- Slotter machines are used to making internal and external Slots, Grooves, Spline, Keyways, regular and irregular dies, punches, blind holes, etc.

- Machining of internal portion and external portion of gears.

- It is used for large products as well as light cuts.

- It is used to construct mechanical concave, convex, and semi-circular surfaces, etc.

- For cutting and machining internal or external gears

- It is used to produce contour surfaces

Advantages of Slotter Machine

The advantages of Slotter Machines are:

- Lightweight and easily transported machine.

- Low capital cost.

- Low Maintenance.

- The finish is accurate.

- Higher efficiency

- Mass production

- Quick drive mechanism

- Uses a single-point cutting tool.

Disadvantages of Slotter Machine

The disadvantages of Slotter Machines are:

- There are many movements that are associated, hence, a skilled worker is required.

- Few types of slotter machines are heavyweight and a little difficult to transport.

Conclusion

Hence, we have a basic idea about the slotter machine. Any questions, please let us know.