Air handlers or Air Handling Units or AHUs are explained along with it’s basic details, definition, working principle, parts or components, description of all parts, applications, etc. In this article, we will learn how Air Handling units, or AHU’s, work. We’ll look at different components of typical AHU’s along with diagrams to clear our basics. An animated video is attached in the middle of the post with the actual site tour & explanation. Let’s explore air handler!

What are Air Handlers or Air Handling Units or AHUs?

Air Handlers Basics

Let’s learn the basics of the air handlers or air handing units or AHUs. We have already learned the HVAC system and understood that air needs to be conditioned based on our requirements. Now, how do we condition air? There are many equipment to do that and air handler or air handling unit is one of them. As the name suggests, it simply air handles as well as conditioning the air.

Air Handling Units or AHU Definition

An air handler, or air handling unit (often abbreviated to AHU), is a device used for cleaning, conditioning (heating or cooling or humidifying or dehumidifying), regulating, and circulating air as part of a heating, ventilating, and air-conditioning or HVAC system.

- An air handler is usually a large rectangular metal box.

- It is consisting of louver, dampers, filters, heating or cooling elements, moisture eliminators, fan or blower to condition air.

- Normally ducting system is connected to the air handler and air is distributed to areas to be conditioned.

- Air handler have one return duct entry so that it takes return air (relatively hot air from he conditioned area) back to the AHU and recirculation continues.

- Recirculation may not be required in many project, that time only supply is provided. In this case, AHU is used only to supply fresh air and it is called fresh air handling unit.

- It is of different sizes based on requirements.

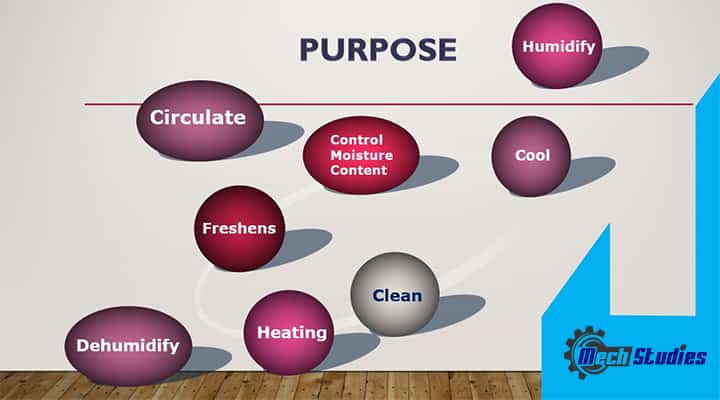

Purpose of Air Handling Units or Air Handlers or AHUs

The main purpose of the Air Handling Unit (AHU) or air handler is to handle the air in terms of cooling, heating, filtration, humidification, etc. as part of a heating, ventilating, and air-conditioning system. The purpose of air handlers shall be as follows,

- It controls the temperature of air, that means it can cool the temperature and heat as well based on requirements.

- It controls the humidity of air.

- Filtrate air

- It circulates air

- Proper air distribution

- Process cooling

- Process heating

We have just elaborated the main function of AHU to understand clearly, as follows:

- Cooling: In extremely hot weather, or where heat is generated, need to cool. It may be required for people, or things, or equipment.

- Heating: In extremely cold weather, or where moisture is too much, needs to be heated. It may be required for people, or things, or equipment.

- Humidifying: In many places, humidity goes below the recommended level. Actually, it should not be less than 40%. Here, water needs to be sprayed to increase moisture content.

- Dehumidifying: In many places, humidity goes more than the recommended level. Actually, it should not be more than 60%. Here, the dehumidifier needs to consider removing extra moisture.

- Filtration: Outside fresh air is not clean, and also inside air will be polluted after sometimes. Hence, filtration is mandatory for the air handling units. There are various filters are used to filtrate as well as to make the air clean.

- Circulation: The air handling unit helps to circulate air, based on the requirements.

- Pressurization: AHU can make the building pressurize so that outside dust cannot enter into the buildings. Remember, the criteria of conditioned air, depends on the project requirements, and type of applications. You can explore our detailed course on AHU

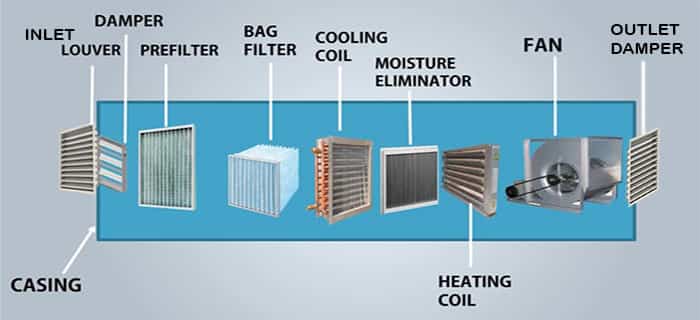

Parts or Components of Air Handling Unit or AHU

The air handling unit, as the name suggests, it handles air. It helps to cool or heat, cleans the air for conditioning. It is abbreviated as AHU, and we get the filtered air from it. There are many components in the air handling unit, are as follows,

- Casing & Base frame

- Louver

- Inlet Damper

- Mixing box Section with dampers

- Filters, including one or more of the following, Pre-filters, medium efficiency filters, final filters & HEPA filters (as applicable)

- Cooling coils / chilled water or direct expansion (DX).

- Drain pan

- Moisture Eliminators

- Electrical heater

- Fan

- Motor

- Outlet Damper

- Door safety limit

- Internal inspection

- Viewing provision

- Humidifier /Dehumidifier

- Weather hood

- Controls

- Vibration isolators

- Flexible connection etc.

Air Flow Path in Air Handlers or AHU units

Before learning the details of various parts in air handling units, it is required to know the air flow & its path to understand the concept of each part. There are three different air handled by Air Handling Unit.

Different Type of Air handled by AHU & Path

There are three categories of air handled by air handlers.

- Fresh Air: The air which is entered from the atmosphere is called fresh air. As this air has been taken from the atmosphere and it is not conditioned is called fresh air. This path is called fresh air path/duct.

- Supply Air: The air which is supplied to the required areas is called supply air. This air is conditioned based on the design requirements. This path is called supply air path/duct.

- Return Air: If the AHU is used to supply only the fresh air after conditioning, then there will be no return air. In this case, 100% fresh air will be conditioned and supplied to the required areas.

However, if the supply air needs to be recirculated, then some percentage of supply air shall be taken back to the AHU again and mixed with fresh air in a chamber. This air which is returned from the conditioned areas, is called return air. This path is called return air path/duct.

Air Flow Path Diagram in AHU

The air path in AHU can be understood from the below diagram.

- Air Flow Path with No Recirculation: Let’s see the below diagram to understand the fresh air and supply air path.

- Air Flow Path with Recirculation: Let’s see the below diagram to understand the fresh air, return air and supply air path.

Description of AHU Parts or Components

01. AHU Casing & Base Frame

Description: The casing is the outer most part of the air handling unit. It is basically housing where all the parts are installed. Air handler unit casing is factory assembled, modular, single skinned, or double skinned with insulation. The entire AHU casing is mounted on a rigid base frame.

Function of AHU Casing: The function of AHU casing, are as follows:

- It housed all parts.

- It protects air leakage or air infiltrations.

- It protects internal parts of AHU.

- It restricts heat transfer with outside area.

- It helps to reduce the noise level.

Characteristics

- Casing shall be designed for indoor/out-door installation.

- Inside and outside of panel walls shall be completely smooth.

- Access doors, service doors are provided.

- Inspection windows are provided in the cooling coil section.

Construction: Normally sheet metal is used for AHU casing, however, for hazardous area application, it can be considered as stainless steel. Typical technical parameters are as follows,

- Inner skin : 0.7 – 0.8mm

- Outer skin: 0.7 – 1.0 mm

- Insulation: polyurethane

- Thickness of insulation: 50mm

- Thermal conductivity: k = 0.017 W/MºK

02. Intake Louver

The intake louver is the first part of the AHU through which air is entered into the unit. The main function of the intake louver are,

- It helps to streamline air.

- It prevents other objects or birds or animals to enter into the AHU.

- There is a fan which sucks air. If intake lover is not there, it sucks other foreign particles from outside.

Normally it is made of sheet steel. In many AHU, intake is ducted and no need additional louver in AHU. In this case, louver is attached with the duct separately.

03. AHU Inlet Damper

AHU dampers are provided at the inlet of the fresh air to control the air flow into the AHU. The damper is provided with an actuator that controls the opening or closing or modulating of the damper to control the airflow rate.

There is one control system to control all of this. There are many projects, where fresh air may contain unwanted gas like H2S. Damper is essential as well as critical in this case. In case of gas detection, this damper is closed in such a way that no gas can be entered into the conditioned areas.

04. Mixing Box & Damper

This is a box of basically a free space. AHU shall be provided with a mixing box and as the name suggests, it mixes return air and fresh air. There is one damper to control the return air flow.

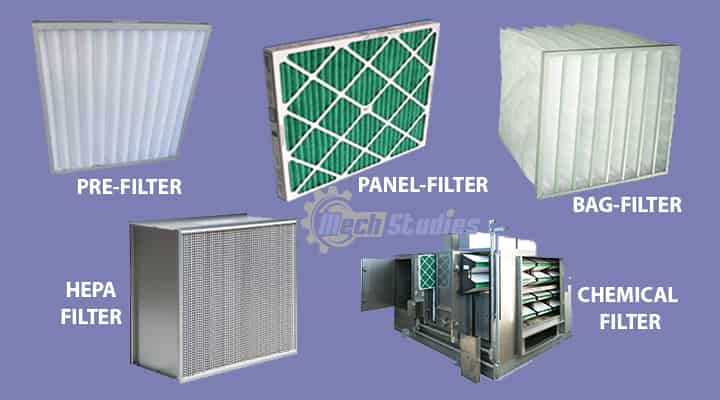

05. Filters

Filters mean the thing which cleans the air. Filters along with filter frame is one the main part of AHU and arranged in banks in sufficient numbers. The numbers of filters are calculated based on air quantity, air quality. Filters have the below characteristics,

- Filter materials shall fire resistant,

- It shall be washable, disposal type,

- Flter housing shall be in such a way that filter replacement will be simply and easy,

- Air should not bypass the filter by anymeans,

- Maximum air velocity through filters shall be 2.5m/s.

- Gaskets shall be provided to prevent bypass of unfiltered air.

- Two full sets of prefilters shall be shipped with each unit.

The following filters are used for air handling units, like

- Prefilters

- Medium efficiency filters

- Bag filters

- Chemical filters

- HEPA filters

Prefilters

Prefilters are the first basic filters in an air handling unit. It filtrates comparatively coarse particles.

- The filter media has an average efficiency of 25 to 30 percent on ASHRAE Test Standard 52-76.

- Filters shall have an average arrestance of 90 to 92 percent as per standard practice.

Medium Efficiency Filters

- The filter media shall have an average efficiency of 60 to 65 percent on ASHRAE Test Standard 52-76.

- The average arrestance shall be 98 to 99 percent, in accordance with that standard. Initial air pressure drop shall not exceed 0.13 kPa at 2.5 m/s velocity.

Fine Filters / Bag Filters

- The shape of this filters is like a bag.

- The filter media shall have an average efficiency of 90 to 95 percent on the ASHRAE Test Standard 52-76.

- They shall have an average arrestance of not less than 99 percent on that standard. Initial air pressure drop shall not exceed 0.20 kPa at 2.5 m/s velocity.

Chemical Filter

The chemical filters are not used in normal areas, however, in case if it is the corrosive atmosphere, chemical filters are used at the fresh air intake.

HEPA Filter

HEPA filters are normally used for precision applications, like medical applications. It is highly efficient and it’s efficiency is 99.97% to 0.3-micron size.

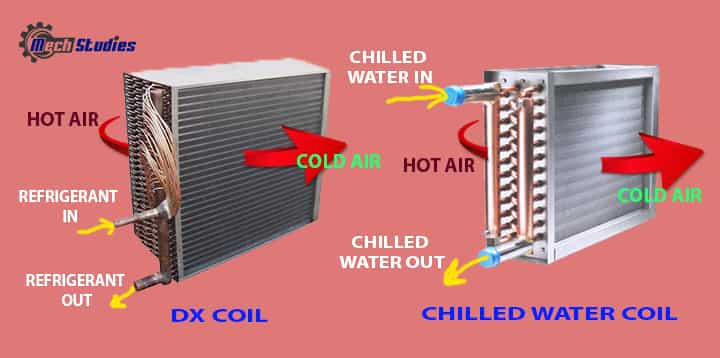

06. Cooling Coil (Chilled Water & DX type)

The cooling coil is the main part for the cooling air or water. It cools the air or water whatever comes in contact. Normally air comes in contact with the cooling coil but for a bigger system like a chilled water system, the cooling coil cools water circuits.

The cooling coil can be classified into two types,

- DX cooling coil which cools air directly. DX is the abbreviation of direct expansion. As air comes into contact with the refrigerat circuit directly, it is called DX coil.

- Chilled water coil where cools water and the water circuits cools air. In the chilled water circuit, air is not comes in contact with the refrigerant, in this case, refrigerant cools the water and that water is circulated into the AHU cooling coil.

It basically acts as a heat exchanger. Copper is used for the material of the cooling coil and it is properly insulated to restrict heat loss that runs outside of the AHU.

- Cooling coil is normally made of coper.

- It has fins to increase the surface area or heat transfer rate.

- Fins can be copper or aluminium. If dissimilar material is used, then coating shall be applied.

07. Moisture Eliminators

A moisture eliminator is used in AHU to separate the moisture or water droplets from the wet air. It is basically formed zig-zag passages. Air can pass through the zig-zag passage but water droplets cannot pass.

Hence, water droplets stuck on the moisture eliminator falls down and accumulate in the drain pan.

- Normally, moisture eliminators with minimum 99.9 % water separation efficiency is used.

- The moisture eliminator is normally used as PVC or HDPE.

Note:

- Air and water droplet has one characteristic, that is if the air velocity is less than 2.5 m/s, then water droplets cannot pass and many times, if velocity is limited to it, moisture eliminator can be avoided. However, for safe side, we used to provide moisture eliminator.

- If the velocity is more than 2.5 m/s sec, moisture eliminator must be provided.

08. Drain Pan, U Trap

A drain pan is provided below the cooling coil to collect the condensate. It is normally made of stainless steel (SS316L) is a common option. The U Trap shall be designed for a water level according to the relevant air pressure differential and in consideration of an additional 50 mm W.G. for reserve. In absence of a U-trap, there may be a chance of outside air entering into the AHU through the drain pipe. A drainpipe is used to remove the drain water accumulated in the drain pan.

09. Heating Coil

In case of a high humid area, the moisture content is becoming more and the same needs to be removed to make it comfortable or acceptable. The heating coil is used for this purpose. In many places, if humidity is too high, duct heaters shall be provided in the individual rooms instead of common heating coils in the air handling unit. Heaters are integral parts of air handlers, based on the requirements. In many cases, the heater is not provided in the AHU, instead, separate duct heaters are provided.

- In case the cold conditions, heater is required to make the air comfortable.

- If the moisture content is too high in the atmosphere, it is required to reduce to make the conditioned air comfortable. Here, the requirement of a heater comes. Whenever required it will be switched on.

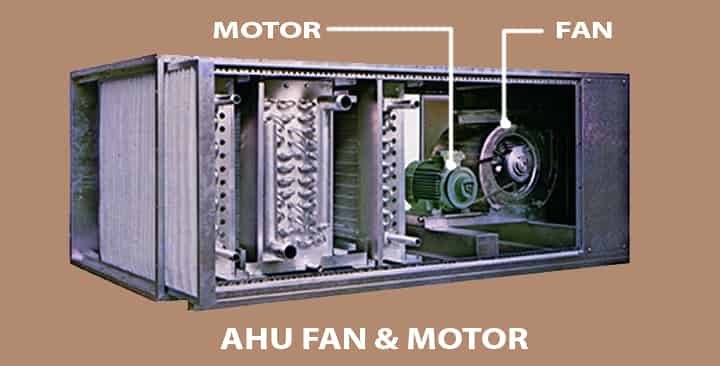

10. AHU Fan

Description: An air handling fan or air handler fan is one of the main components for supplying air into the required areas. Normally double inlet double width (DIDW) type centrifugal fans are widely used for air handling units. Single inlet single width fan is also used based on the requirements.

Now a day, EC fans are also used in many AHUs, to optimize power consumption. The fan can be driven by motor or variable speed drive (VFD) based on requirements. In many big AHU units, multiple fans are also considered. Normally, double inlet double width type centrifugal fans are used with forward or backward curved impellers. Fans can be mounted as below based on project requirements,

- Top discharge

- Side discharge

- Bottom discharge

Function of AHU Fan: The function of the AHU fan, are as follows:

- It supply the conditioned air into the buildngs.

- It sucks the outside air

- It sucks the return air too.

- It build pressure within the building.

Characteristics

- Fan shall be statically and dynamically balanced.

- Fans shall be with aerofoil shaped blades.

- Fan shall be provided with vibration isolation system so that vibration will not able to transfer.

- It shall be belt driven and will have a guard.

- High efficiency.

- Fan bearing shall be self cleaning.

- Outlet air velocity considered as 12 m/s max.

Construction: Normally, the material of fans shall be based on application or type of projects, however, the following materials are widely used,

- Fan casing : Galvanized sheet metal

- Base frame: galvanized steel

- Fan shaft: Carbon steel C45

11. Motor

The fan is driven by a motor.

- It is totally encased, foot mounted.

- It is fan cooled.

- Normally it is IP55 with Class ‘F’ insulation.

- It consists a power operating margin around 25%, however, it varries based on the project requirements.

- Fans and shafts shall operate well below their critical speeds.

12. AHU Outlet Damper

AHU dampers are provided at the discharge of the conditioned air. It is basically placed at the fan discharge. The damper is provided with an actuator that controls the opening or closing or modulating of the damper to control the airflow rate. There is one control system to control all of this. It is mandatory to control the flow.

- In case more cooling required, damper will be open fully and full conditioned air can be supplied to the areas which needs to be conditioned.

- In case less cooling required, damper will be open partially and partial conditioned air can be supplied to the areas which needs to be conditioned.

13. Weather hood (for outdoor AHU)

In case air handlers are kept outside, a factory-installed weather hood is used to protect the unit from the sun.

14. Controls

To control the air handling unit, a dedicated control system is inbuilt in it. Control system used to control the following:

- Air flow rate

- Temperature of air

- Humidity of air

- Air qualityt etc.

It can be operated through a thermostat and connected to direct digital controls or even a PLC or DDC system. There are many items are associated with the control system,

or DDC system. There are many items are associated with the control system,

- temperature sensors,

- humidity sensors,

- switches,

- actuators,

- Controllers, etc.

15. Vibration isolators

AHU fan creates a vibration on the base of a fan as well as AHU base frame. Hence, to reduce this vibration, a vibration isolator is provided at the base of the fan so that no vibration will be transmitted.

16. Flexible connection

AHU fan is connected to a ducting system and the vibration of the fan will be transmitted to the ducting system. It can reduce the rigidity of the duct supports. Hence, a flexible connection is provided between the fan and ducting system to limit the transmission of vibration.

17. Refrigerant

It is the main working fluid in the HVAC system and it flows through within the cooling coil for the DX-type system. Nowadays, the following environment-friendly refrigerants are used in various industries,

are used in various industries,

- R410a

- R134a

- R407c

- R1234yf etc.

Above all refrigerants are having negative effects on the environment and scientists are continuously trying to develop the best refrigerant. Recently R1234yf is the best refrigerant which will soon be used in various machines. Remember the refrigerant shall be selected based on ODP and GWP.

Types of Air Handlers or Air Handling Units or AHUs

Air handlers are classified as follows:

Based on type of fan’s operation

- Draw though

- Blow through

Based on cooling coils

- DX type AHU

- Chilled water AHU

Based on Nos. of AHU fans and motors

- Single fan AHU (1 AHU Fan + 1 Motor)

- Duel fans AHU (2 AHU fans + 2 Motors)

- Multiple fans AHU

- Duel Motor AHU (1 Ahu Fan + 2 Motors)

Based on Fresh air & Recirculation

- Fresh Air Handling Unit or FAHU (AHU with 100% Fresh air)

- Recirculated AHU (AHU with recirculation)

Let’s see all types of AHUs to have a basic idea,

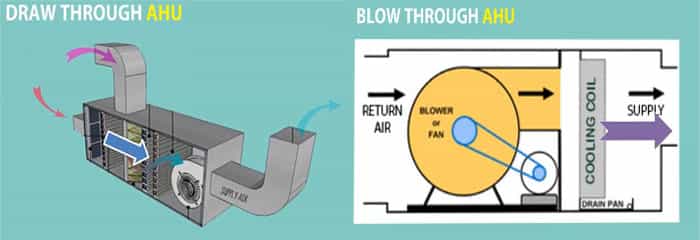

Draw-Through AHU

In the Draw-Through type air handlers, the fan is used to pull the air through filters, cooling coil, mixing box before discharge.

- Fan can be mounted vertically or horizontally.

- The fan has negative pressure in the suction region.

- Draw through means AHU fan draws the air through filters, cooling coil.

- This type of AHU is used in various industries.

- Fan is in downstream of cooling coil. No possibility of transferring water droplets, into the areas to be conditioned.

- Length is less, as no need to make any distance between cooling coil & fan. So, cost is less comparatively.

- Motor heat is transferred to the room, which is the disadvantage. However, due to other advantages, draw through AHU is opted in most of the projects.

Blow-Through AHU

In the Blow-Through type air handlers, the fan is used to blow the air through filters, cooling coil, mixing box before discharge. Positive pressure will be created after the fan.

- Fan is in the upstream of cooling coil.

- There is a possibility of transferring water droplets, into the areas to be conditioned. So, moisture may be present in the conditioned air.

- Airflow may not be uniform.

- There is a possibilty of creating turbulance. So, there should be some distance between cooling coil and fan to stablize the air.

- This distance increase the overall length of AHU and increases the cost.

- Motor heat is not transferred to the room, as fan motor assembly is on the upstream of cooling coil.

DX type AHU

DX is the abbreviation of direct expansion. Direct expansion means when the air is directly coming in contact with cooling coils. The cooling coil is with refrigerant and heat transfer happens between the refrigerant and the air. This cooling coil is called a DX coil.

- DX coil is having refrigerant.

- Refrigerant takes up the heat from air.

- DX coil is with fins to increase the surafce area as well as better heat transfer.

Chilled Water type AHU

Chilled water type AHU means the AHU which is having a chilled water cooling coil. As this cooling coil is having chilled water instead of refrigerant, it is called a chilled water cooling coil.

- Chilled water coil is having water.

- Water takes up the heat from air.

- Normally for big capacity units, this coils are used.

Single Fan AHU

Normally AHU comes with a single fan with one motor. Single fan AHU means only one no. of AHU fan.

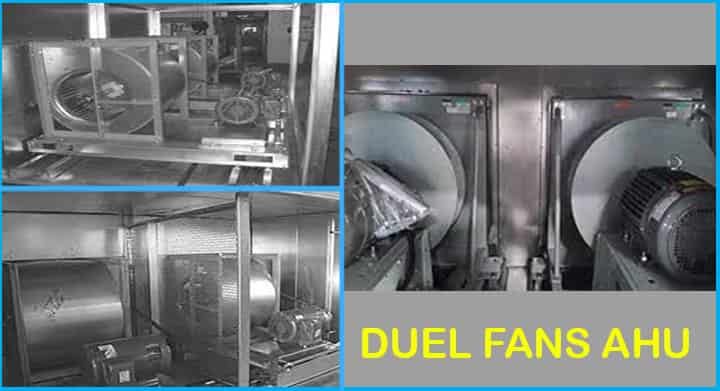

Duel Fans AHU

Duel fans AHU are not generally used, however, it can be used in the below case,

- If static pressure is very high, two fans can be used to meet the project requirements.

Multiple Fans AHU

The AHU which consists of more than two fans, is called multiple fans AHU.

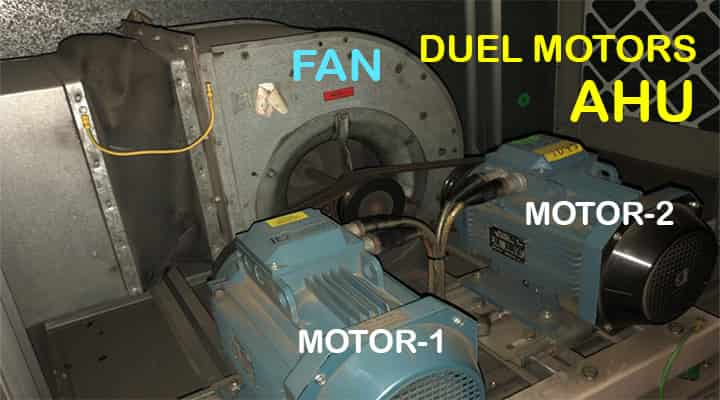

Duel Motors AHU

Duel motors AHU is not generally used, however, it can be used in the below case,

- If space is limited to consider two AHUs, a single AHU with duel motors can be adopted.

FAHU (AHU with 100% Fresh Air)

In this type of AHU, there is no recirculation, only fresh air is entered into the AHU and conditioned.

- No opening for return air.

- As this unit handles 100% fresh air, it is called fresh air handling unit or FAHU.

Recirculated AHU (AHU with Recirculation)

In this type of AHU, air will be recirculated instead of 100% fresh air.

- This is the fresh air entry to the AHU. Apart from fresh air, there will be recirculated air as well.

- So, in the recirculated AHU, recirculation of air is the main criteria. In many recirculated AHU, fresh air is not there, based on project requirements.

Would you like to know about chiller basics

Location of Air Handling Units or AHUs

Location of Air handling units, or AHUs depend on the type of project, space availabilty, building sizes, etc. AHUs can be placed,

Within a Room, called AHU Room.

- AHU room can be placed in different floors or basement.

- In multi story buildings, AHU room are placed in different floors, based on requirements.

- AHU Room many times are kept in basement as well.

Not in a Room or Outside

- Roof, in many projects, AHUs are kept exposed to the atmosphere. Many substation projects, it is done.

- In many projects, AHUs are placed outside the building without any room.

Diagram of Air Handling Unit or AHU or Air Handlers

Before going to the working principle, let’s have look of the diagram of air handlers.

- Louver –> Damper –> Mixing Box –>Prefilter –> Medium Filter (if applicable) –> Final filter –> Cooling coil –> Moisture eliminator –> Heaters –> Fan/Blower –> Damper –> Ducting system –> Conditioned Space

- Conditioned Space —> Return air –> Damper –> AHU

How Does AHU or Air Handler Work? Working Principle

Let’s learn the working principle of air handling unit. Its very simple and we will discuss it step by step:

Step#1 Fresh air entrance: Fresh air enters through the intake louver of the AHU. Louver helps to avert any animals or bird entry into the AHU. In the sand zone or desert zone, a special louver, called sand trap louver is used with a ducted transition piece and connected to the AHU inlet damper.

Sand trap louver is having zig-zag passages and air can easily pass through it but sand cannot. Hence, sand falls down at the bottom and leaves through the bottom holes automatically.

Step#2 Filtration: It has two options,

- AHU is used only to supply fresh air: Fresh air then pass through the different kinds of filters, like prefilter, medium filters, fine filters and removes all impurities or unwanted foreign particles.

- AHU is used for recirculation: After louver there is one return air opening through which return air from the conditioned space comes into the AHU. Fresh air is then mixed with the return air and reduce the temperature of the mixure in the mixing box section and then pass though the filters.

Step#3 Cooling: After filters, the air gets cleaned and passes through the cooling coil.

- Cooling coil is chilled water type: Air comes in contact with chilled water coil and cooled.

- Cooling coil is DX type: Air comes in contact with DX coil and cooled.

- A drin pan is provided for the water drip below the cooling coil.

Step#4 Moisture eliminating: Cool air then passes through the moisture eliminator and removes all moisture from the air.

Step#5 Heating process: After the moisture eliminator, the air is passed through heaters to control/remove the moisture content. In many cases, heaters are not provided in AHU, instead, it is provided in the duct based on the project requirements.

Step#6 Conditioned air supply: The air is then sucked by the fan and transferred to the required areas to be conditioned. The fan is connected to a ducting system. This ducting system helps to distribute the air properly. For small capacity or small rooms, the ducting system is not used.

Step#7 Air circulation in system: Conditioned air is taking heat in the areas and comes back to the AHU through return air opening/damper and mixed with the fresh air. This process continues and AHU works.

Step#8 Controls & interface: There are many instruments in the AHU to understand the filter health, AHU health, chilled water temperatures, pressures, airflow rate, etc, which helps to meet the demands as well as maintain the good health of AHU.

Air Handling Unit or Air Handler or AHU Specification

The basic parameters for AHU specification, shall be as follows:

- Type of unit

- Type of discharge

- Thickness of casing

- Cooling Coil Load

- Sensible Load

- Outside DBT

- Outside WBT

- Total Airflow capacity

- Fresh Air Flow

- Filter details

- Cooling coil materials

- Fin materials

- Fan capacity

- Fan material

- Motor power

- Unit size

- Unit weight

- Accessories

AHU Standards

- ARI 210/240-2008 – Performance Rating of Unitary Air-Conditioning and Air-Source Heat Pump Equipment

- ARI 270-95 – Standard for Sound Rating of Outdoor Unitary Equipment

- ARI 360 – Commercial and Industrial Unitary Air Conditioning Equipment

- ARI 410 – Forced Circulation Air-Cooling and Air- Heating Coils

- ARI 430 – Standard for Central Station Air-Handling Unit

- UL 900 – Standard for Air Filter Unit

- ASTM B 280-3 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

AHU Manufacturers

There are so many companies that manufacture Air handlers, few of them are listed,

- Carrier

- Daikin

- SKM

- Trane

- Saiver

- Voltas

- Blue Star etc.

Frequently Asked Questions – FAQs

What is an Air Handling Unit?

An Air Handling Unit (AHU) is a machine in an HVAC system which is used to condition the air like cooling, heating, filtration, circulation, and control its moisture content.

Is an Air Handling Unit the same as HVAC?

HVAC means heating ventilation & air conditioning and AHU means air handling unit. Now, HVAC is a vast system and it may consist of different kinds of systems as well as different kinds of equipment. AHU is only a part of it.

For example, consider a DX-type HVAC system that consists 2 nos. AHU, 2 nos. ACCUs, piping systems like refrigerant condensate piping, etc., air distribution systems like diffusers, ducting, etc. So, from this example, it is clear that the entire system is called an HVAC system and AHU is simple a part of it.

What is difference between AHU and FCU?

AHU is the abbreviation of air handling unit and FCU is the abbreviation of the fan coil unit.

AHU is used for small, medium, and very large capacity applications, however, FCUs are used for small capacity applications.

AHUs are used for central air conditioning, however, FCUs are used normally for local applications.

AHUs can take fresh air and condition it, however, FCUs are normally not taking outside air and only used for recirculation & conditioning purposes.

How does an air handler work?

The working process of the air handling unit or air handler is very simple! We can explain it as below:

Fresh air enters through the intake louver or inlet damper. After that one free space is available which is called a mixing box. A return air opening is there which is connected to a return air duct that is coming from the room.

Fresh air and return are mixed in the mixing box and then this mixed air will pass through a set of filters like prefilters, fine filters, etc.

After filtration, clean air passes through the cooling coil & is cooled and passed through a moisture eliminator to eliminate moisture. After that, it passes through a heating coil if heating is required.

A separate dehumidifier is also installed if required. After that air needs to be circulated to the required areas. This circulation is done by a fan. Normally DIDW type centrifugal fan is used for air circulation. AHU has a control panel and it is connected to a control system for controlling as well as monitoring the system.

Do air handling units have refrigerant?

Refrigerant is used as a medium of heat transfer and it takes heat from the area which is to be air-conditioned and released to the atmosphere for air conditioners. The air handling unit has a cooling circuit that is connected to condensing unit. A refrigerant is flowing through this circuit and conditions the required space.

The refrigerant in the Air handling unit or AHU takes heat from the space to be conditioned and circulates to the condensing unit through the refrigerant pipes. So, refrigerant is a medium for this type of air handling unit.

However, it is not mandatory to have refrigerant in all AHUs. For a bigger system, chilled water type AHUs are used where refrigerant conditions the water which is called chilled water, and the same chilled water is circulated to the AHU cooling circuit. In this case, refrigerant is not a part of AHUs.

Where should I place my air handling unit?

It is based on the application, type of building, type of AHUs, etc. Normally, it can be placed in a separate AHU room, or basement, or individual AHU room on each floor, or even outside as well.

For example:

In case of a large building, the capacity of each floor is very high and on each floor one dedicated AHU room is recommended.

In case of a small building, based on the capacity of AHU, only a single AHU room may be sufficient for the entire building.

In case of an industrial building, outdoor AHU is used without any dedicated room. In this case, double skin AHU is mandatory.

Is air handler a furnace?

The main purpose of a furnace is to produce heat and it cannot cool any medium. However, an air handler can heat or cool the air based on the requirements.

How long does an air handler last?

Air handler is the most common in the HVAC system and there are various types of air handler available in the market. Normally, the air handler is designed considering 15-25 years. In many applications, it is designed for 30 years as well.

What is the difference between a heat pump and air handler?

Heat pumps and air handlers both are used to condition the air. Normally, in a cold region, heat pumps are preferred. Heat pump transfer outside heat into the room and maintain comfort condition, on the other hand, air handler produces cooling effects or heating also based on requirements.

Can you put an air handler outside?

Normally, air handler put inside. However, it is placed outside as well based on the requirements.

Three things need to keep in mind:

· Casing or skin is preferable to double skin, especially if it is placed at hot region.

· If it is having fresh air system, need to check that there should have sufficient clearance.

· It should have proper access.

Conclusion

So, finally, we have got a basic idea about Air handler or Air Handling Units along with its basic details. If you have any questions, please let us know, cheers!