What is brazing process, explained along with meaning, definition, flux, process, types, steps, advantages, disadvantages, etc. Also, we have covered a brief comparison of welding vs brazing at the end. Let’s explore the process!

What is Brazing?

Brazing Meaning & Basics

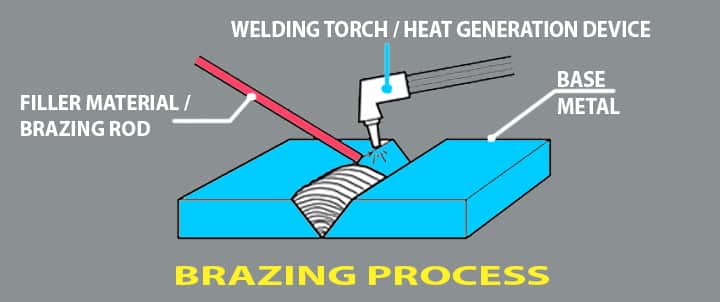

The brazing process is one of the metals joining processes. Basically, in this process, the two or more metals are joined together via melting and flowing a filler metal into the joint while the filler metal having a lower melting point than the adjoining metal. You may find it somewhat identical to the welding but it differs from the welding process.

- In case of the welding process, the metals are melted and then they are joined but in brazing, the filler material is used.

- We will see more about the difference between brazing and welding processes later in this post.

Brazing Definition & Process

In this process, the filler metal flows into the gap by use of capillary action.

- The filler metal will be brought slightly above its melting temperature while being protected by the suitable atmosphere usually a flux.

- After that, it will flow over the base metal and later cooled to join the workpieces together.

There are different types of brazing processes available we will check each one of them. Also, the parameters like flux, filler materials, and the atmosphere in this process. These three are the basics of the brazing process.

So, let’s start with them first. The brazing process depends upon the temperature. Because as the temperature will increases the alloying action of the filler metal will increase as well. Basically, the brazing temperature selected should be above the melting temperature of the filler metal. The proper or best possible temperature for the following factors.

- Getting the lowest possible braze temperatures

- Minimizing the heat effects on the assembly

- Minimizing the filler metal/base metal interaction

- Maximizing the life of jigs and fixtures used

Also, the temperature is also selected according to the requirement of the product.

Brazing Flux

The flux is used for preventing the formation of oxides from forming while the metal is heated.

Also, another work of the flux is to clean any contamination left on the brazing surfaces.

- The flux examples like traditionally used borax are one of them.

- Now some new fluxes are available like some active chemicals like fluorides.

- Flux can be applied in lots of ways.

- In ways like, paste, liquid, powder, or pre-made brazing pastes.

The flux flows into the joint of two metals to the heated joint and displaced by the molten filler metal entering the joint. Flux selection is based on their performance with the base metals. To be effective and better the flux should be chemically compatible with both the base and filler metal being used.

Filler Materials in Brazing

Filler metal is the term used in brazing to describe the alloy (or elemental metal) which forms the joint.

- It is placed between two (or more) components (the parent materials), and having a lower melting point than them, is melted and allowed to solidify, forming a joint within a brazing assembly.

- The various varieties of alloys are used as filler materials in the brazing.

- The selection depends upon the ability to wet the base metals, withstanding the service condition, and melt at a lower temperature than the base metal.

Depending upon the use the filler is placed at the desired locations or applied during the cycle. Some examples of filler materials used are,

- Aluminium silicon

- Copper

- Copper-silver

- Copper-zinc

- Nickel-Alloy

Atmosphere Necessity in Brazing Process

We already know the brazing depends upon the temperatures. The temperatures required are pretty much high with oxygen-containing environments. So, there is a need for using the environment other than the air. Following atmospheres are used in this process,

- Air

- Combusted fuel gas (Exothermic generated)

- Combusted fuel gas (Endothermic generated)

- Ammonia

- Hydrogen + Nitrogen

- Inorganic vapours

So, these are some basic things to know about brazing. It depends on the above parameters. Also, there are different types, all are discussed to get the basic idea.

Types of Brazing

Torch Brazing

Torch brazing is one of the most common methods of mechanized brazing that is now in use.

- The torch brazing is best suited for a small production volume or in some specialized operations.

- This process can be done in three ways.

- These are manual, machine, and automatic torch brazing.

If we talk about the manual torch brazing in this heat is applied using a gas flame placed on or near the joint which is being brazed. The torch can be held in a fixed position or depending upon the operation.

- The drawback is as it’s a manual process the worker needs to be skilled and also the cost.

- In case of machine torch brazing, these are used where repetitive braze operations are being carried out.

- It is a mixture of manual and automatic torch brazing.

- Because of this, it reduces the requirement of skilled labour.

In case of automatic torch brazing the manual work is completely eliminated. Only the loading and unloading of the machine is not automated. This method gives high production rates, uniform braze quality, and reduced operating costs.

Furnace Brazing

The furnace brazing is kind of semi-automatic process and is widely sued in the industrial brazing operations.

- It can be adapted for mass productions and unskilled labor.

- The furnace brazing is used for mass productions due to the advantages like, its produce a large number of small parts which are easily jigged or self-locating.

Furnace brazing are also having four types.

- The first one of the batch type furnace brazing. In this process, there are relatively low initial equipment costs, they can be turned off and on at will. This results in reduced operating expenses. The batch-type furnaces are suited for medium to large productions.

- The second continuous type of furnace brazing is suited for the steady flow of similar parts through the furnace. These furnaces are often fed with the conveyor at controlled speeds. These are suited for large-scale productions and require very low manual labor requirements.

- The retorts furnace is somewhat like the batch ones. But the retort ones use sealed lining known as the retort. These are generally used in batch or semi-continuous versions.

- The next up is the vacuum furnaces that are economical method oxide prevention. Vacuum brazing is used heavily with refractory materials. The main types of vacuum furnaces are single wall hot retort, double-wall, and cold wall. These are batch types and suited for medium to high production volumes.

Silver Brazing

The silver brazing is also known as the hard soldering. It uses an alloy which is silver based filler. The braze alloy joins the materials and compensates for the difference in their expansion rates.

- It also provides a cushion between the hard carbide tip and the hard steel, which softens impact and prevents tip loss and damage—much as a vehicle’s suspension helps prevent damage to the tires and the vehicle.

- Consists of many different percentages of silver and other metals like copper, zinc, cadmium.

- Silver brazing is widely used in the tool industry to fasten hard metals.

Braze Welding

The braze welding makes use of bronze or brass as a filler material. They are coated with flux to join the steel workpieces.

- The equipment needed for braze welding is kind of similar to brazing.

- But the braze welding requires more heating than brazing hence the acetylene or methylacetylene-propadiene gas fuel is commonly used.

If we compare braze welding with fusion welding there are lots of advantages of braze welding over fusion welding. Like, allows the joining of dissimilar metals, minimize the heat distortion and reduce the need of expensive pre-heating.

there are lots of advantages of braze welding over fusion welding. Like, allows the joining of dissimilar metals, minimize the heat distortion and reduce the need of expensive pre-heating.

Cast iron brazing

Basically, the welding of cast iron is the brazing operation.

- It has a filler rod made of nickel.

- The ductile cast irons and others are brazed using the cast iron brazing process.

Dip Brazing

The process of dip brazing is generally suited for the brazing of the aluminium. Because the air is excluded and thus prevention of formation of oxides.

In this process the parts to be joined are fixtured and the brazing compounds are applied to the mating surfaces in a slurry form.

Vacuum Brazing

As the name suggests the vacuum brazing is performed in a vacuum chamber vessel.

- It is the vacuum joining technique that offers lots of advantages. Like, it is extremely clean, superior, flux-free, and has high integrity and strength.

- The commonly vacuum brazed products are aluminum cold plates, plate-fin heat exchangers, and flat tube heat exchangers.

Now we have seen all the types of brazing used generally. Now its time to know the advantages and disadvantages of the brazing processes.

Don’t be confused with soldering, as Soldering and brazing both are different process. Let’s see the difference between brazing and welding.

Difference Between Brazing and Welding

As we have said, earlier let’s know the brief difference between brazing and welding. Let’s see brazing vs welding!

| Sr no. | Brazing | Welding |

| 1 | Brazing joints are weaker than welding joints. But they are stronger than the soldered joints. | These are strongest joints used to bear the high load. |

| 2 | Less skill is required to join the metals. | High skilled labour is required. |

| 3 | Workpieces are heated below their melting point. | Work piece are heated till their melting point. |

| 4 | No heat treatment is required after the brazing. | Heat treatment is required to eliminate the undesirable effects of welding. |

Advantages of Brazing

The advantages of brazing are as follows,

- Brazing can be used to join dissimilar metals.

- The brazed joints are pressure-tight.

- Brazed components preserve the protective metal coating.

- It does not melt the base metal thus it allows much tighter control over the required tolerances.

- Produces a clean joint.

- Complex parts and multi-part assemblies can be brazed effectively.

- It can be adapted for mass productions and it’s very easy to automate. for more profits and making the process more accurate and easier.

- It can be also done on the cast and wrought materials.

Disadvantages of Brazing

The disadvantages of brazing are as follows,

- The strength of the brazed parts is less as compared to the welded parts.

- If higher service temperatures are used it may damage the brazed parts.

- The brazed joints required pretty much higher level base metal cleanliness.

- To control cleanliness adequate fluxing agents are required.

- The join color can be different from the base metal thus it may create an aesthetic disadvantage.

Applications of Brazing

Let’s see the application of this process,

- Used for fastening of radiators, electrical parts, tanks, pipe fitting, and axles.

- Welding of dissimilar metals.

- For the joint of band saws in bicycle parts like rims and frames.

- Used in the vacuum interrupters.

Conclusion

So, we have got an idea about brazing process, its types, steps, advantages, disadvantages, etc. Any comments, please write in the comment box!

Nice post I like the layout of your page by the way.

I discovered your web site very informative maintain up the superior work

This is very fascinating, You’re an excessively skilled blogger. I have joined your feed and sit up for looking for more of your fantastic post. Also, I’ve shared your web site in my social networks!

Just wish to say your article is as surprising. The clearness for your post is simply spectacular and that i can suppose you are knowledgeable in this subject. Well together with your permission allow me to take hold of your feed to keep updated with imminent post. Thanks one million and please continue the rewarding work.

Your posts constantly possess much of really up to date info. Where do you come up with this? Just stating you are very inspiring. Thanks again

Easily, the post is really the greatest on this laudable topic. I concur with your conclusions and will thirstily watch forward to your future updates. Saying cheers will not just be sufficient, for the great c lucidity in your writing. I will instantly grab your rss feed to stay privy of any updates. Solid work and much success in your business enterprise!

This post post made me think. I will write something about this on my blog. Hmm…

Sweet website , super style and design , really clean and utilise pleasant.

Your post offers confirmed beneficial to me personally. It’s very informative and you’re simply certainly extremely knowledgeable in this region. You have opened up my eye to be able to various views on this particular matter together with interesting and strong content.

Hello! I just would like to give you a enormous thumbs up with the great info you could have here on this post. We are returning to your website for much more soon.

I simply couldn’t leave your web site prior to suggesting that I extremely loved the usual info an individual provide in your guests? Is gonna be again continuously in order to investigate cross-check new posts.

I am glad to be a visitant of this pure weblog ! , appreciate it for this rare info ! .

Sup, just wanted to say that this site feels great, keep it up.

I’d have to check with you here. Which isn’t something I usually do! I get pleasure from reading a put up that can make people think. Additionally, thanks for allowing me to remark!

Hi my friend! I wish to say that this article is awesome, nice written and include approximately all significant infos. I’d like to see extra posts like this.