What are chain drives? In this article, we are going to learn a core concept of chain drives, definition, meaning, different types of chain drive, advantages, disadvantages, applications, etc. Let’s explore!

What are Chain Drives?

So, what is a chain drive? Let’s learn from the basics.

Chain Drives Basics

Do you know there are a plethora of ways by which you can harness energy to produce energy or motion? In mechanical engineering, there are different kinds of equipment that are quite effective and help to attain effective energy.

- One of the major equipment or machine parts that are on the top for harnessing the rotational motion is through drives.

- One of the most effective and important methods of power transmission is in the vicinity through the use of chain drives and sprockets.

In Layman’s language chain drives or sprockets are simplistic components that can nurture the rotational motion for generating energy.

Chain Drive Example

For example, our bike has a sprocket that is attached to a chain that provides rotational motion to the wheels, due to which we are able to move our bike. Here, we are providing hands on knowledge about the chain drives and all the related information that can come handy in understanding the importance of these efficient mechanical components.

Let’s delve into the information and start with the general definition of the chain drive.

Chain Drives Definition

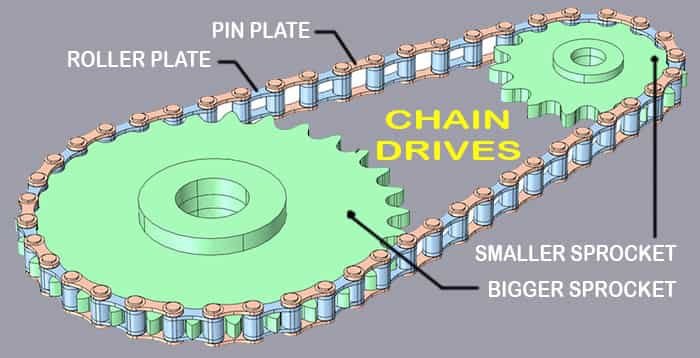

Chain drives are the components that are equipped with an endless series of chain links that are meshed with toothed sprockets.

- These components help in transmitting energy with the help of rotational motion.

- These chains are manufactured by rigid links that are hinged with each other.

- It helps in providing much-needed flexibility for twisting the driving and driven wheel.

- In addition to that, these wheels are also equipped with projecting teeth and specifically fit in the counterpart recesses.

- The arrangement of wheels and chains are attached in a way that enables them to move together without the danger of slipping and also maintaining a velocity ratio.

Sprockets or sprocket wheels are the toothed wheels on which the chains got lodged. These wheels are just like spur gears. The effective functionality of these chain drives is to transmit power and motion from shafts. These are mostly used in those machines which have smaller distances between the center of the shafts such as,

- motorcycles,

- road rollers,

- agricultural machinery,

- bicycles, etc.

Functions of Chain Drives

As we know that chain drives are equipped with numerous chain links which are meshed together with toothed sprockets. These chain drives are especially used for three essential function:

Conveying materials

The foremost use of these chain drives is in different kinds of industries. It is widely used at such places where there is a need for,

- moving,

- sliding,

- pushing,

- carrying different materials.

These chain drives can be also used directly or indirectly by attaching,

- buckets,

- rollers,

- frames or

- turning rollers,

- conveyor belts etc.

Transmitting or channelizing the power

Chain drives are usually used for transmitting power from one part to another. Specifically, these are helpful for transferring torque and speed with the help of sprockets and linked chains.

- Chain drives are specially designed for those works which provide the ability to produce a positive speed ratio and effective ability to channelize a large amount of torque within a small space.

- These chain drives are widely used for different industrial applications.

- It can be used in those places where there is a need for moving and rigging heavy materials, overhead hoists, conveying materials, etc.

- One of the use is that keeps massive importance.

It helps in regulating the driver’s output speed by changing gear ratios between the sprocket and the driver.

Timing Purposes

Apart from all the usages of chain drives the massive use of this component is also as a synchronizer or maintaining the time movements. These are specifically used in different industrial combustion engines that use these chain drives for regulation valve timing.

Terminology in Chain Drives

Chain drives can be understood by getting an idea of all the effective terms associated with this. There are some of the important terms that are quite important. Without the knowledge of these terms, it is quite hard to understand the kinematics and working of chain drives.

The following are some of the basic terms associated with chain drives:

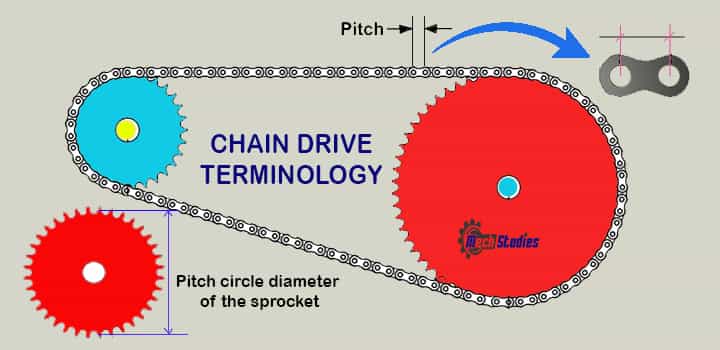

Pitch of the chain

The distance between the hinge center of the link and the corresponding center of the hinge center of the adjacent link is known as the pitch of the chain. This is important to understand in a way that helps in understanding the different parameters.

Pitch circle diameter of the sprocket

Sprocket is the component on which the chain is wrapped around.

- It comes in a circular shape.

- The circle drawn through the chain sprocket center with adjacent circles from the same center is known as a pitch circle and the diameter of that circle is known as pitch circle diameter.

These two are the basic terms that come handy while understanding the kinematics of chain drive.

Types of Chains

While understanding about chain drives it is mandatory to get an idea about its different types. Though the whole drive is a separate component which consists of chains and sprocket.

Here we have to understand the importance of chains as these chain drives are classified on the basis of chains only. These chains are further divided as per their usage. These are classified in three groups.

- Hoisting and hauling chains

- Conveyor chains

- Power transmitting chains

Here, we are discussing the above types of chains with their subdivided classifications:

Hoisting and Hauling Chains

Hoisting and hauling chains are widely used for industrial purposes.

- These are also known as crane chains.

- In a nutshell, we can say that these chains are specifically used for hauling and hoisting.

Hoisting and hauling chains are further subdivided into three types. They are as follows:

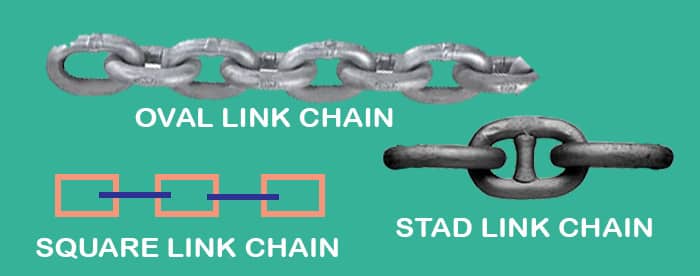

Oval link chain

The chain with oval links are those in which the main design is oval in shape. In these the joints are welded to each other.

- The sprockets used for this kind of chain are equipped with a repository that holds the links.

- These are basically used in anchors for marine works or for chain hoists.

Square link chain

As the name suggests these chains are equipped with square-shaped links. These kinds of chains are basically used in dredges, hoists, and cranes.

- The manufacturing cost of these links is comparatively lesser.

- The main disadvantage is the kinking factor which occurs when there is an overloading scenario.

Stud link chain

Stud link chain means the chain with oval or square shape with study which helps the chain to make more strengthen.

- It is used in ship anchoring.

- For high loads, it has opted.

- This link prevents the chain from deformation against high loads.

- Few heavy cranes have also used this type of chain.

Conveyor Chains

The conveyor chains are typically used for conveying or elevating the materials. These are manufactured of malleable cast iron that generates below level smooth running qualities.

These are mainly used in those places where there is a need of slow speed material shifting. Basically, there are two types of conveyor chains:

- Detachable or hook joint type chain

- Closed joint type chain

Power Transmitting Chains

The power transmitting chains are the most important and widely used chain types that are used specifically for the transmission of power. The distance between the center of the shafts is minimal. These chains need efficient lubrication. Basically, there are three types of power transmitting chains. They are as follows:

Block chain

Block chains are the type of power transmitting chains that are used in the pre-stage of the power transmission development.

- The main disadvantage of this kind of chain is the heavy noise that occurs when there is motion related to leaving or approaching the sprockets.

- This occurs due to the rubbing effect of the chain teeth and links.

- These kinds of chains are used as conveyor chains also because of its effective working at low speed.

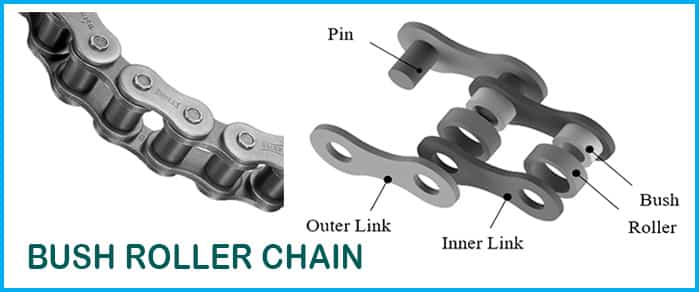

Bush roller chain

When there is a need for optimally strong and simplistic chains, these kinds of chains are used.

- It provides optimal efficiency and service under optimal and severe conditions.

- The noise produced due to the chain motion is also low as the point of impact is at a low scale.

- These chains are preferable for those places where there is a need for less lubrication.

- The kinematics of these chains are quite effective as these chains can elongate a bit with the continuous wear and stretching action.

The bush roller chains are equipped with,

- bushes,

- rollers,

- inner plates,

- outer plates.

In these, a pin passes through the bush which is attached to the roller between both sides of the chain. These rollers are mainly free to rotate which protects the sprocket wheel effectively.

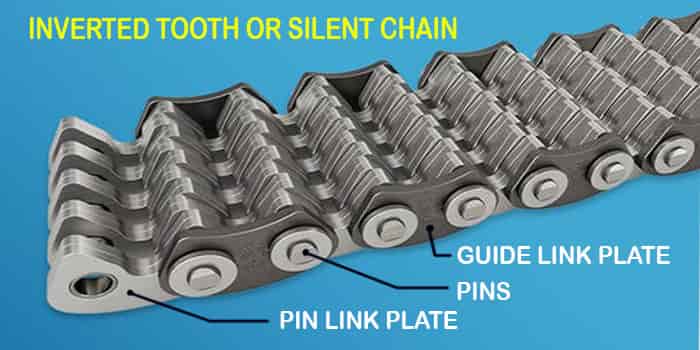

Inverted tooth or silent chain.

While using chains the factor of producing excessive noise is the main reason for wear and tear. It is specially designed to cater to all the disadvantages associated with motion-oriented defects such as stretching, noise, and other ill effects.

The Pitch of the chain increases when there is stretching action. The unavailability of relative sliding action makes it perfect for the rugged use. if these chains are effectively lubricated then you can expect maximum durability and service. With these chains, one can easily attain quieter working and smooth movement.

Advantages of the chain drives

There are numerous advantages that are provided by chain drives. Here are some of the following:

- In the chain drives, the tolerance between shaft center distance is restricted to exact dimensions for a given group of gears. These exact specifications make it quite effective for different kinds of use.

- The installation of chain drives is quite easy. This is the best choice for those who don’t want complicated installation techniques.

- The possibility of redesigning and configuring chain drives is quite easy as compared to others.

- The performance of chain drives is effective and better than other drives under the shock loading conditions.

- Chain drives are effective for fluent motion as the operating loads are spread over numerous teeth. As compared to other kinds of drives it is quite beneficial.

- The bearing loading is reduced substantially as these chain drives do not require tension on the slack side which belt drives do have.

- When it comes to occupying space, chain drives acquire minimal space for a given speed and loading condition than other alternatives such as belts and pulleys.

- The manufacturing and maintenance cost of chain drives is quite low as compared to other drive systems.

- With chain drives we can get maximum transmission efficiency which can be up to 98%.

- With this we can get an optimal velocity ratio as there is no option of any type of slippage.

Disadvantages of Chain Drives

- While using chain drive there is a possibility of velocity fluctuation and the chains get stretched under rigorous conditions.

- The chordal effect is the major reason for these chains of suffering from excessive vibrations.

- The cost associated with the production of chain drives is comparatively more than other drive options.

- While installing chain drives it is quite important to mount it accurately and precisely.

- The maintenance needed by chain drives is also high as one has to provide continuous lubrication and adjustment of slack.

- Without proper lubrication these chains are more prone to wear and tear.

Applications of Chain Drives

The core applications of chain drive are vivid. Here are some of the essential applications of chain drives:

- It is used majorly in motorcycles.

- Due to the low manufacturing cost of chains it is widely used for industrial purposes such as for cranes, conveyors etc.

- One of the wide usage is in one of the best inventions i.e. in bicycles.

- Chain links are widely used in overhead hoists especially in those industries where there is a material movement from above.

Conclusion

With these being said the use of chain drive is vivid. The understanding of chain drive and it’s all aspects lead to having better knowledge. This article provides a holistic view of all the aspects and generates a deep sense of knowledge about chain drive. Though the study of chain drives can be elaborated further. Further Study