The piston is described along with basic understanding, definition, types, characteristics, functions, advantages, disadvantages, etc.

What is Piston?

Piston Basics

The piston is an integral part of especially in the reciprocating engines. They are an important aspect of automobile vehicles. Not only in engines it can be found in,

- Compressors,

- Pumps,

- Hydraulic & pneumatic cylinders, and much more.

Basically, it is a small moving part enclosed tightly by the piston rings. We will get to know more details of pistons and all the information associated with pistons.

Piston Definition

The piston is defined as a piece of metal that works against fluid pressure in a cylinder.

- Mostly, the piston used in the engines is known to all, they expand and compress the fuel with the help of connecting rods and other parts inside the combustion cylinder.

- In case of the pump, the force is transferred from the crankshaft to pistons for compression or ejecting the fluid.

- So, all I have to say is there are wider applications of pistons and not only in the engines.

Piston Shape & Materials

Talking about its shape, it has a cylindrical kind of shape. In case of engine, the piston’s reciprocating motion is converted to a revolving motion for crankshafts. They are made of different materials. Generally, pistons are made of cast aluminium alloys. There are other materials as well like,

- Cast iron pistons,

- Cast steel pistons,

- Cast aluminium,

- Hypereutectic,

- Alluminium alloy, Aluminium forged pistons.

These materials have high strength and are used according to the requirements. For low-speed application, cast iron is used and for high-speed application, alluminium alloy is used. So, before knowing more about the piston types and parts, let’s know about the general functions of pistons.

Functions of Pistons

The function of piston are as follows,

- In engines, Transmit the force of explosion to the crankshafts.

- Serving as a heat transfer medium for cylinder walls.

- Pistons also acts as a controlling valve.

- It helps to guide the connecting rod movement.

- Pistons kind of forms a seal so that the gases should not escape from combustion chamber to crankcase.

So, to get the effective operations as expected from the piston, they need to have some characteristics. Here are some desired characteristics a piston should have for a ideal working operation.

Desirable Characteristics of Pistons

Let’s refer to the main desirable characteristic of the piston, as below:

- The piston should be silent in operation.

- It should have corrosion resistant properties.

- It should be lighter in weight.

- Piston should have long life and high thermal conductivity.

- It should shortest possible length and the design should be such that seizure does not occur.

There are various types of pistons and they are named according to their various working principles and arrangements. We will see the generally used pistons each in brief details. Let’s know about the parts or components of the pistons.

Parts of Piston

There are few parts of a piston, as follows:

- Piston rings

- Piston Ring grooves

- Piston skirt

- Piston pins

- Piston head

- Piston bearings

Let’s try to look at all this in brief,

Piston Ring

The piston rings are kind of split rings that are mounted on the recessed area of the piston.

- Generally, there are 3 types of piston rings used.

- Pistons can have one or three rings according to the requirements.

- The rings are mounted such that the constructions look tapered.

So, what is the function of piston rings? They seal off the combustion chamber and regulate the lubricating oil usage. Also, they serve to conduct the heat away to the cylinder bore. As we said above there are 3 types of rings used. Let’s check each one of them.

Compression rings

The compression rings are located at the top side of the piston nearer to the combustion chamber.

- They are also known as the gas rings or pressure rings.

- As the function of rings, the compression rings prevent the combustion gases from leakage and help to transfer the heat from the piston to cylinder walls.

Oil Scraper rings

The scraper rings are located in the middle of compression rings and the oil rings. They have a tapered surface and does the work of sealing the combustion chamber and wipe the oil off from the piston cylinder.

Oil control rings or Oil rings

These are located below the scraper rings. The oil rings consist of two surfaces with holes all around. These slot holes allow the oil to flow back into the sump. As the piston moves back and forth the oil rings will remove the excess oils from the cylinder walls.

Piston ring grooves

Piston groove means the grooves or the slots where the piston ring fits.

Piston Skirt

The round section on the piston is known as the piston skirt.

- They are made of cast iron material because of high wear resistance and self-lubrication properties.

- It has grooves to mount the piston oil rings as well as compression rings.

The function of piston skirt is to guide the piston travelling up and down the cylinder. The design is made such that it will help the piston to overcome the side forces. There are two types of skirts used.

is to guide the piston travelling up and down the cylinder. The design is made such that it will help the piston to overcome the side forces. There are two types of skirts used.

- Full skirt – The full skirt is known as the solid skirts; they are tubular shaped and commonly used in large automobiles.

- Slipper skirt– The slipper skirt is used on the pistons of motorcycles and cars. The slipper skirt has a part of skirt that is cut away to leave only the surfaces on the back and front of the cylinder wall.

Piston Pins

You may have heard the name “Gudgeon Pin” if you ever studied or know about the piston. The Gudgeon pin provides the bearing support and helps piston for functioning properly. In simple words, it joins the connecting rod and piston-like a pivot joint. There are three methods by which pins can be mounted on the pistons.

- Stationery fixed – In this method, the pin will attach the boss of the piston using screws.

- Semi floating – This pin will attach the connecting rod in the middle and the pin will move freely within the bearing and at the bosses.

- Full-floating – In full-floating the pin is secured by plugs. This one can oscillate at the bosses as well as the connecting rod.

Piston Head

The piston head is also known as the piston crown. As the name suggests it is the tope portions of the pistons. The combustion gases come in contact at the piston crown. As the combustion gases temperature are high hence the piston heads are made of special alloys, steel alloys. Here are the functions of the piston head.

- The piston head creates a swirl so that the combustion will be uniform and also regular knocking.

- The piston crown acts as a heat barrier as it restricts the high-temperature heat reaching to lower pistons parts.

- The pressures responsible for knocking in the cylinder, the piston head can contain them.

Piston Bearings

The place where the pivotal rotations take place the bearings are provided.

- They have a semi-circular shape and fit in these bores on the pivot points.

- The shells of piston rings are available at the big end where the rod connects the crankshafts.

- The bearings are made of lead, copper, silicone aluminium materials.

Check a nice VIDEO from Habib Mechanics!

Types of Pistons

There are lots of types of pistons based according to their arrangements and applications. So here are the generally used types of pistons.

- Offset pin type

- Cam ground type

- Oil cooled type

- Taper type

- Steel wire-wound type

- Aconoguide type

- Piston with heat dam

- Autothermic type

- Bi-metal pistons

Let’s learn the basic of all these types of piston,

Offset pin type piston

As the name suggests in this type, the piston is offset towards the major thrust side of the piston. This arrangement helps to reduce wear as well as piston noise.

- If you are wondering what is major thrust side, the thrust side is the one that is loaded during the power event.

- Whereas the minor thrust side is the one that is loaded during the compression event.

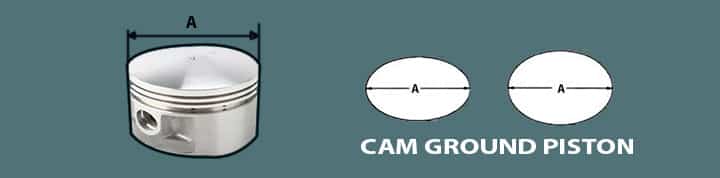

Cam ground piston

Mostly, the pistons used are cam ground pistons. These are not perfectly round and the diameter of these pistons is large on the non-thrust side. Because when the piston temperature increases, they tend to expand.

Oil cooled piston

In this oil-cooled type, a cavity is provided underneath the piston crown. Why is that? Because to reduce the piston temperatures at the top ring and prevent carbon formation in the groove. They are provided in medium and heavy speed diesel engines.

Taper pistons

In this type, the crown side of the piston is smaller than the skirt diameter end. When the high temperature comes to the crown the side expands and piston diameter becomes uniform under conditions.

Steel wire-wound Pistons

The band of steel wire under the tension is put between the oil ring and piston pin.

Aconoguide piston

These pistons are equipped with the raised pads that are specially shaped and assists the hydrodynamic lubrication.

Piston with heat dam

In these pistons, there is a groove cut near the top of the piston. It will reduce the heat travel from crown to skirt. So, the skirt will run cooler and will not expand much.

Autothermic piston

These pistons contain low expansion steel inserts at piston pin bosses. When at the higher temperatures the arrangements will cause the piston to expand along with the piston pin.

The contraction occurs in the direction perpendicular to the piston pin due to metallic action.

Bi-metal pistons

As the name suggest they are made of two metals. The one is steel and other is aluminium. The skirt is made of steel whereas aluminium cats inside forms piston head and piston pin bosses. There are some cases, the piston failure can be occurred. So we should know how the usual piston damages and their descriptions.

How Does the Piston Work?

Working Principle

Energy is produced in the cylinder due to the combustion process. Piston is operating within the cylinder and it is connected to the crankshaft through the connecting rod. So, after combustion, this energy is transferred to the crankshaft through the connecting rod. Piston also dissipates the heat produced from the combustion. Let’s see the step by step working principle of piston.

Step by Step Working Principle

- The piston moves from top dead centre to bottom dead centre,

- The vacuum is created within the cylinder.

- Air fuel mixture enters due to the vacuum.

- The piston compresses the mixture.

- Pressure & temperature is increased.

- Power stroke or Fuel-burning happens.

- The piston moves from top dead centre to bottom centre.

- Power is transferred to the connecting rod.

- From connecting rod, power is transferred to crankshaft.

- Finally, exhaust gases are removed by exhaust stroke.

Piston Failures

Let’s learn the basic of failures,

Piston scuffing

The piston scuffing is caused due to excessive heat due to which the piston will expand and become tighter in the cylinder. Due to expansion the lubricant will be squeezed out of cylinder walls causing the metal-to-metal contact.

Burnt Piston

The burnt piston may be a major cause of detonation and preignitions. In the detonation the gases release tremendous amount of energy. In preignition the burning occus generally near the piston head.

Piston dry run

The dry run piston failure can be caused due to unburned fuel condensation at the cylinder. This results into long narrow friction marks due to interaction of sliding parts.

Piston pin boss damage

When the mechanical overstressing of the piston happens the piston pin boss gets damaged. Also, if the oil supply is insufficient a crack will occur in the piston pin boss and later it will spread evenly on the normal loads, and eventually, the piston will split.

Advantages of pistons

There are many advantages of the piston, as follows:

- The pistons are simpler mechanically.

- They are flexible and have higher reliability.

- They have a good weight to power ratio.

- Less maintenance, vibration, and noise in operation

- Multi-fuel capability, it can work with any fuel

- Less manufacturing costs due to mass productions

- Piston gives a high degree of maneuverability

Disadvantages of pistons

There are many disadvantages of the piston, as well:

- Fuel economy may become poor

- The stability of fuel is a problem

- The part-load efficiency is poor

- The reduction gearing is required

As we have discussed earlier there are wider applications of pistons in lots of machines. The common applications of the pistons are given below.

Applications of the piston

- The most popular and known application is the use of pistons in the combustion chamber of IC engines.

- In a self-loading firearm, the piston is used to push the bolt.

- They are used in hydraulic pumps and hydraulic cylinders as ram or double-acting actuators.

- Air compressor.

- In air conditioners to help circulate the working fluid.

- In steam engines to convert the stream to power motion.

- Heat pumps.

- Other automobile parts and equipment.

Conclusion

Hence, we have got a basic idea about what is piston, piston definition, types, different parts, advantages, disadvantages, etc. Any doubt, please let us know. There are many interesting articles, you can refer,

bookmarked!!, I love your blog!