In this article, we will learn casting patterns along with its definition, materials, different types of casting, parameters, etc. Let’s explore!

What are Patterns in Casting? Definition

Let’s start with the basics of casting patterns along with the definition.

Casting Patterns Basics

Right from the evolution of humanity, man has been using his brain to its utmost capacity. Creative thinking and intelligence have helped us to develop different things that reduce labor.

- We shaped tools, weapons out of stones and wood, which are already present in nature.

- With the due course of time, we have discovered different kinds of elements in nature, such as copper, silver, gold, and numerous others, which are available in nature in the form of nuggets and ores.

- We melted and provided them a designated shape as per our desires.

- We found it easy to melt different elements such as copper, iron, and gold with the help of charcoal and firewood, thus making these metals prominent ones that can be used among other natural materials.

Casting vs Patterns

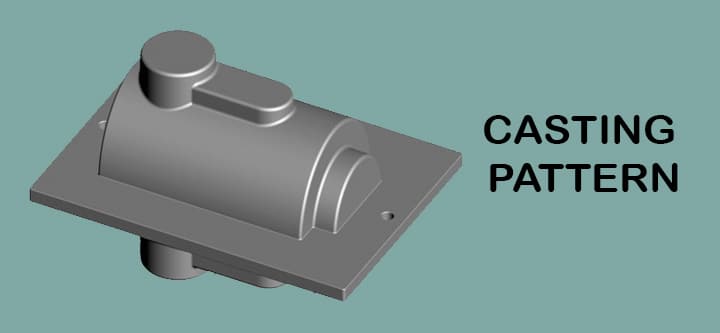

One of the core processes that have been providing massive help to humanity is casting. Casting is a process in which we develop different shapes and sizes of things with the help of molds and patterns. Here we will discuss the main thing that helps us cast different shapes, known as patterns.

History of Casting Patterns

The first casting patterns are known to be used probably 3500 years in Mesopotamia with the help of beeswax. One of the oldest living proofs of complex Pattern in which a frog cast in copper has been found.

What is Pattern?

In the casting process, Pattern refers to the equipment’s replica, which provides the casting process’s output. Patterns are then molded in sand forms mold.

- When we fill a mold with molten metal, then there is a formation of casting.

- A whole pattern plays an influential role in the casting process as they specifically provide perfection and quality in a specific casting process.

- The Pattern is the core need for mold manufacturing, and it remains at a bigger size of the casting.

- While selecting this Pattern, there should be an integrated approach so that it can sustain rough handling.

- These patterns can be made up of different metals such as brass, aluminum, wax, and plaster.

This article will provide us an overview of patterns, their manufacturing materials, and the properties that provides efficient patterns. In addition to that, we will also discuss the different kinds of patterns that make them easy to cast. Let’s start with the introduction of patterns and their importance in the casting process.

Casting Patterns Definition

In a holistic approach, the Pattern in casting is the prominent object for casting. Casting patterns are specifically used to shape the casting mold, and hence the mold crates metal parts.

- For this reason, the casting pattern acts as an essential component that helps provide the final parts.

- For this reason, it is prescribed to get as many details as we can while designing pattern phrases.

- This should be the core responsibility of the casting parts designer.

The manufacturing of casting patterns is not only about shaping mold cavities, but it also refers to the approval of accuracy in dimensions, mold removing method, and also scientific feeding system. It is vital to consider different things while making a pattern in which the material used is the foremost. We can get different elaborative ideas in due course of time.

Materials Used for Making Patterns

Numerous materials can be used to make Patterns in which metal, plastic, and wood are the foremost.

- The selection of these materials holds the key for effective and beneficial Patterns.

- The different parameters include the complexity of the Pattern, accuracy in the dimensions, and size of the pattern number of casting products needed to make from a pattern.

- Here we will provide an elaborative analysis of different kinds of material, the reason behind using those, and their core applications.

Numerous materials are used for making patterns. The following are those materials and the consecutive reasons behind using them with their pros and cons.

Pattern Material Metal

Most of the patterns are made up of metal as they can provide a smooth finish to the products. Apart from that, the patterns which are made up of metals are suitable for mass production. One of the prominent processes through which patterns are easily made pup of metals is casting. However, numerous metal patterns are made with the help of the casting process with double shrinkage tolerance.

Pros

- Durability is among the foremost attribute that is being provided by the metal patterns. Due to this, these patterns are less prone to abrasion as sand is used as a mold. These can be used in massive quantities also.

- With the help of patterns manufactured from metals, it is pretty easy to get a smooth surface finish.

- Where there is a need of providing fine surface details there we can use metal-oriented patterns

- These patterns don’t get deformed while storing.

- We can attain minute dimensional tolerance with metal-oriented patterns.

- The metal pattern is equipped with par strength that makes it suitable for compelling reasons.

Cons

- One of the foremost backdrops of metal patterns is rust and corrosion.

- The metal patterns are pretty heavy.

- These patterns are not cost-effective and don’t flourish the need for small quantity production.

- The complexity in repairing and modifying the metal patterns persists and causes numerous problems.

Pattern Material Wood

Wood is the most prominent and widely used material used for pattern making. These are used for different reasons as they have some of the best qualities abundantly available and come cheap. The core reason behind the use of wood in pattern making is the quickly acquiring shape, and it also consists of minimal weight compared to other materials used for pattern making.

- There are some of the backdrops in the wood pattern that are distorted of dimension.

- This occurs due to the absorption of moisture.

- When we use wood for large-scale production, then the abrasion takes place.

The most commonly used for pattern making are walnut, deodar, pine, mahogany, and teak.

Pros

- The prominent advantage of using wood in the making of Pattern is its inexpensive and readily available attribute.

- It has a minimal weight that makes them quite apt for use in large pattern making.

- Wood can easily be shaped and fabricated in the desired form.

Cons

- Wood is prone to shrink or swell due to the change in dimension, which occurs due to moisture absorption.

- Abrasion is among his apparent failure that makes it relatively ineffective to use for large scale production.

- While using wood, one needs to provide high dimension tolerance.

- It is pretty hard to furnish the patterns with minute detailing.

- Low strength is among the prominent cause that makes it ineffective.

Pattern Material Plastic

Numerous kinds of plastics can be used for Pattern making in the casting process. The prominent reason behind this is the durability of metal and lightweight characteristics as same as wood. The most common kind of plastic used for pattern making is the Epoxy resins which thermo are setting plastic. The plastic patterns are manufactured using different kinds of molds made up of clay or POP.

which thermo are setting plastic. The plastic patterns are manufactured using different kinds of molds made up of clay or POP.

Pros

- Plastic patterns are lightweight and relatively cost-effective.

- The core attributes that are essential for any materials used for making Pattern are present in plastic, such as formability and durability.

- There is a need for accuracy and precision there, and we can use plastic without any second thoughts.

- With plastic patterns, we can get effective surface finishing.

- The plastic patterns are equipped with excellent compressive strength.

Cons

- Fragility is the core reason behind the patterns made up of plastic.

- Plastic is not as good as metal as they are not abrasive resistant.

- In complex patterns made up of plastic needs metal reinforcement.

Pattern Material Wax

Wax is among the most effective materials that are used for pattern making. The core benefit of wax patterns is the minimal distortion on mold while removing the Pattern; thus, it provides optimal surface finishing and accuracy in dimension. In some of the casting processes, such as investment casting, it is widely used. Paraffin, bee wax, and shellac are the most prominent kinds of wax used for pattern making.

Pros

- The core benefit of wax is its lightweight and easy to manufacture approach.

- With this, one can attain a top surface finish, which is the core need of any product manufacturing through casting.

Cons

- Not as strengthened as metal or wood pattern.

- It is pretty hard to get practical shapes with this kind of pattern material.

Apart from all the above materials, numerous other materials can be used in the making of patterns.

- Play wood and particle boards are among the wooden patterns which can be used for various reasons.

- They are readily available in different thicknesses and are also equipped with optimal strength.

- With this, you don’t need seasoning at large.

- Apart from this, polyurethane foam is also used for pattern making, which is effective for small-scale light works.

- These are equipped with a meager amount of ash content that makes them suitable for pattern making.

In addition to these, there are numerous materials; plasters are also a kind of pattern-making materials that provides effective materials. These are commonly known as Plaster of Paris and also known as gypsum plasters. These are equipped with optimal compressive strength. There is different kind’s gypsum available as per their setting time and expansion rate. The primary benefits of this are abundantly available and easily workable at a cheap cost.

Classification or Types of Patterns

The classification of patterns is attained based on different kinds of work. These works deepen the construction of patterns. Here we are providing some of the types of widely used patterns in most casting processes. They are as follows:

- Solid or single piece pattern

- Two-piece Pattern

- Multi-piece pattern

- Gated Pattern

- Skeleton pattern

- Sweep pattern

- Match plate pattern

- Shell pattern

- Segmental Pattern

- Follow board pattern

- Lose piece pattern

- Cope and drag pattern

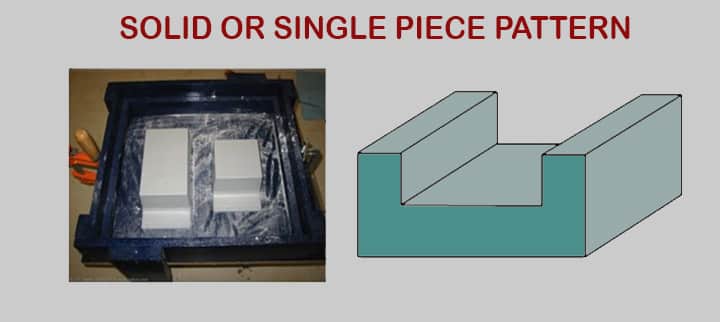

Solid or Single Piece Pattern

This is among the most inexpensive kind of Pattern among all the other ones. The main applications of this kind of Pattern are in simple processes where we need small-scale production.

- One of the essential attributes of this kind of Pattern is the absence of joints in the mold area.

- In this kind of Pattern, one part is called a flat surface, which is used for parting plane.

Applications:

Some of the core applications of this Pattern are in the production of large castings such as those used to stuff engines, and it also helps in the manufacturing of simple shapes. Most of them are in rectangular or square blocks.

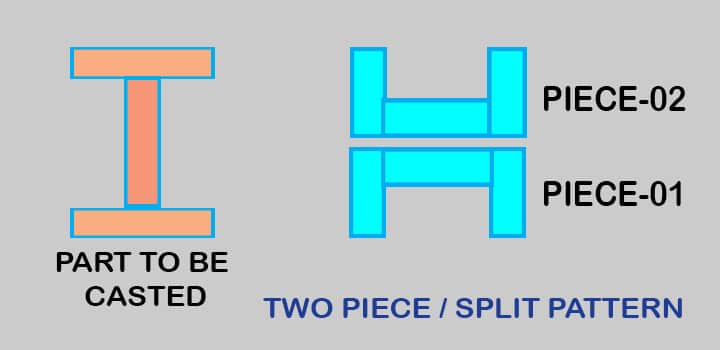

Two-Piece or Split Pattern

A two-piece pattern or split piece pattern is one of the best pattern types used to make an intricate casting. The shape of the casting is usually the deciding factor that provides the idea of the parting plane.

In this, the parting plane can be of flat or any redundant surface.

Applications:

- It is used in those places where there is difficulty to withdraw casting from the mold.

- It is also used in those places where there is a need for depth.

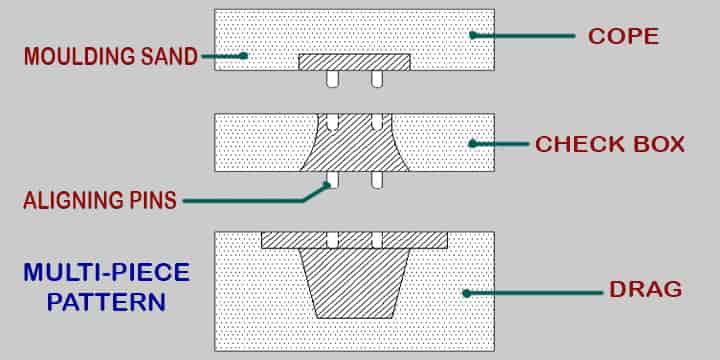

Multi-Piece Pattern

Some casting products are pretty tricky and complex to attain. In such places, this kind of Pattern is being used. In this type of Pattern, three or more patterns are included.

These three parts are equipped with top, bottom, and middle parts. The top part is coping, the bottom part is the drag, and the middle part is known as the check box.

Applications:

The core applications of this kind of multi-piece pattern are in those places where the product has different parts, and they are pretty complicated.

Match plate pattern

This is a split pattern in which the drag and cope are on the adjacent faces of metallic plates. The metallic plate provides the names of the match plate. With this Pattern, the user requires minimal work under which they can get maximum results. These are pretty expensive though it helps to get

Applications:

The core applications of these kinds of patterns are in the different manufacturing industries.

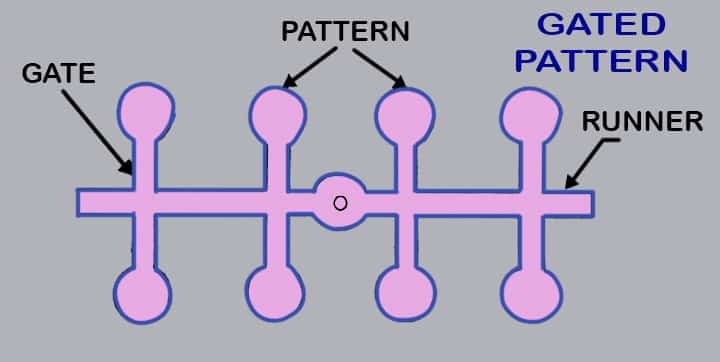

Gated Pattern

These kinds of patterns are used to manufacture numerous components inside a particular mold. The core definition that helps us understand the gated patterns is the availability of one or more patterns.

- In this Pattern, the joining is done based on gates.

- It effectively uses gates.

- One of the significant backdrops of these is the expensiveness.

Applications:

- These patterns are used for small castings due to their high cost.

- These small castings are used for mass production.

- It is among one of the efficient ones that makes it quite essential.

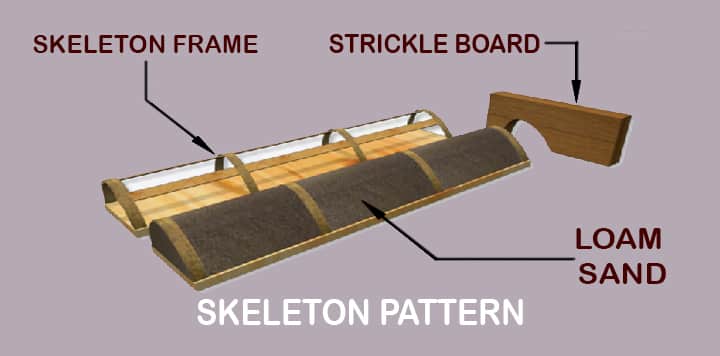

Skeleton Pattern

Where there is the need for accessible and not-so-complicated shapes and sizes, skeleton patterns are used. While using skeleton patterns, the main backdrop is the mere number of usability as we can use it for a minimal number of components.

It is pretty expensive, and it is not viable to use this kind of Pattern on the economic front.

Applications:

- The most prominent use of this kind of Pattern is in-floor welding as well as the process of the pit.

- These patterns effectively help molders.

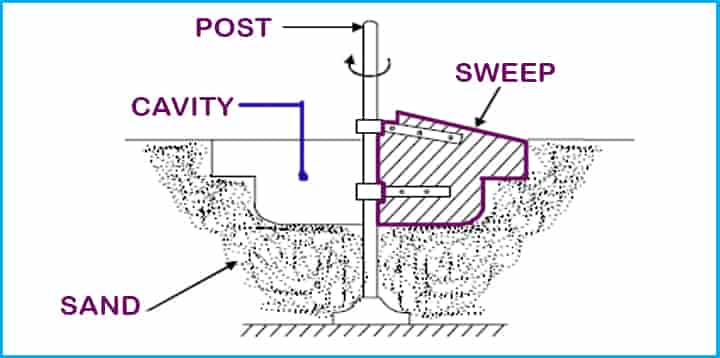

Sweep Pattern

This is one of the patterns that make use of the wooden board. The mechanism of the sweep pattern is entirely redundant as in this, the spindle is effectively directed in the vertical direction, and the base is effectively attached with sand that provides practical support to the mold.

Applications:

- These are the patterns used in the case when we need to cast quickly in a short period.

- Sweep patterns effectively hold three essential parts: base, sweep, spindle, in which sweep is a wooden board.

Loose Piece Pattern

A loose piece pattern is among that efficient kind of solid Pattern that is quite helpful for casting. This kind of Pattern needs skilled labor as these are pretty expensive. With the help of this Pattern, different kinds of projections can be made by the mold.

Applications: The loose piece pattern can be used where there is a need to make accurate casting products.

Cope and Drag Pattern

There are certain kinds of patterns that are known as split patterns. This Pattern has a drag and copes on different plates. Cope and drag patterns are equipped with two parts that are uniquely molded on the molding box. After molding parts, these are effectively combined to form the whole cavity.

Applications: The core applications of cope and drag patterns are producing massive castings where the mold is quite heavy and doesn’t comply for a user to handle.

Shell Pattern

When there is a need to get hollow-shaped products, this kind of Pattern is used. In this, most of the resultant product is obtained under allowances.

Applications: The core applications of this kind of Pattern are to cast hollow objects.

Parameters for the Selection of Pattern Materials

After getting comprehensive information about the Pattern and the materials used to make it, it’s time to get acquainted with the different essential parameters that are pretty effective while selecting the pattern materials. The following are some of the factors that define the selection of pattern materials:

- The shape and size of the object to be cast.

- The quantity or volume of production.

- Precision, dimensional accuracy, and surface finish are adjudged.

- The need or possibility of design alteration.

- The method used in the molding.

- The cost associated with the pattern material.

- The attributes of a good pattern.

The above points specifically clear the core points on which we can choose effective pattern material, but some of the core features of pattern materials make them reasonably practical. Those are as follows:

- Cost-effective

- Lightweight and water-resistant

- Rigidity and long-lasting

- The simplistic design and repairable attributes as per the industry standard

Apart from these, some ambiguities make the patterning process quite rugged. The structural problems can be mending with different allowances such as Draft Allowances, Shake allowances, shrinkage allowances, distortion allowances, etc. in addition to these, and the following attributes can also help in choosing the types of patterns:

- Attributes of the specific casting process

- Quantity of castings that are to be created

- Physical specifications such as dime sin of the casting

Pattern Allowance

Allowance means additional space. In case of casting patterns, the allowance means the excess dimension which is given to the pattern for casting to avert,

- Any kinds of shrinkage,

- draft,

- problem in machining,

- any kinds of distortion.

Pattern allowance are normally few types, as follows,

Shrinkage Allowance

- After solidification, normally metal shrinks.

- Its size increases.

- To accommodate this additional sizes, pattern is made little large with respect to casting requirements.

- This additional allowance is shrinkage allowance..

- Its very small and measured in mm/m.

Machining Allowance

- In case of sand casting, the surface is not very smooth.

- This rough surface creates problem for maching.

- To avert this problem, some extra amount of metal is introduced for proper maching.

- This allowance is called machining allowance.

The machining allowance depends on,

- Size of casting

- Type of metals

- Shape of the casting

- Moulding methods

Draft Allowance

- If the edge of pattern is exactly vertical, then during the withdrawal of pattern, there is a chance to break the edges of mould.

- If the pattern is slightly tapper, this problem can be avoided.

- So, tapper means nothing but providing some draft into the patrtern.

- This tapper allowance is known as draft allowance.

Distortion Allowance

- During casting, when the metal is stated to cool, there may be a chance to distort the casting due to uneven stress.

- To avoid this distort, an allowance has been given on the opposite direction which is called as distortion allowance.

- There is a necesscity to provide a distortion allowance in the ‘U’ shaped casting , basically both the leg needs to have some distortion without keeping parallel.

Shake or Rapping allowances

- Shaking or rapping increases the mould cavity.

- But for small or medium types of moulds, its very less.

- In case of bigger mould cavity, there should have some allowance for shaking or rapping.

- This allowance is called as rapping allowance.

Conclusion

With the elaborative analysis of patterns, now we can understand all the processes related to pattern making and the different kinds of materials that can be used to make patterns. The materials selection is a core process of pattern-making that provides a practical understanding of using the same. In addition to these, we also provided some of the main kinds of Patterns widely used in different casting processes. With that, we can choose an effective one as per our need and type of product.

Following that, some factors also affect the selection. With the proper knowledge of that, we can use them in the best possible ways. There are much more information available for pattern making and the materials involved in the manufacturing. We will discuss them in different articles.