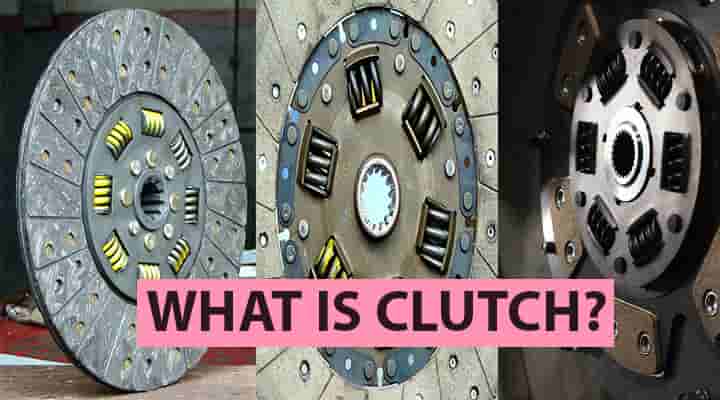

In heavy industries or automobile industries, what is clutch widely used mainly in automobile industries, whenever motion or the transmission of power needs to be provided or controlled. We cannot move an inch without automobiles now a day. When you are in the car and sitting beside the driver seat, you will see the driver uses a clutch to control the car. Let’s explore the clutch!

What is Clutch – Meaning

A clutch is a well-known term in mechanical engineering which is used to provide the transmission of power from one component to another. Among the two members, one is a driving member and another is a driven, member.

- These two members can be engaged or disengaged based on transmission requirements.

- In an automobile, the clutch engages or disengages two parts, one is the engine and another one is the gearbox.

- Here, the clutch helps to transmit the power from the engine to the gearbox which prides motion into the wheels of the vehicle.

Why do clutches require?

In automobiles, there are rotating shafts and which are necessary to connect by the clutch. One shaft is driven by the engine and it may run all the time. Whenever you want to stop your vehicle or again want to drive then you have to use a clutch.

The clutch connects the engine and another shaft which is to be driven so that the driven shaft will spin at the same speed or different speeds based on gear arrangements. When the vehicle needs to be stopped, the clutch will disconnect. The clutch is essential because,

- It transmits the maximum torque of the engine.

- The clutch engage itself gradually and avoid sudden jerks.

- It is able to dissipate heat generated during operation.

- Dynamically balanced even also in high-speed engine applications.

- It helps to damp vibrations

- It eliminates noise produced during power transmission.

- Small size to save space

- Easy to operate

- Light weight

- Trouble free operation

- Long life

- Easy to inspect

- Easy operation, maintenance & repair

History of Clutch

A dry single-plate clutch was first developed by Duryea in 1893, however, it was further developed by Englishman Herbert Frood in 1921 which didn’t burn out in few hundred miles.

Clutch Definition

A clutch is defined as a device which is used to transmission of power from driving shaft to driven shaft by engaging or disengaging.

In this mechanism, the driving shaft is directly connected to an engine or motor and driven shaft get the power for the further utilization.

- The clutches are used to control the motion between two components.

- The clutch consists of various parts like friction surface, diaphragm spring, coil spring, pins, clutch paddle, hub, etc.

- The most commonly used clutch is friction clutch in the automobile industries.

- The clutch paddle is pressed for the change of gear based on the speed requirements.

Parts of Clutch

There are different types of clutches and their working principles are different. However, to understand the parts of clutch, basic parts are captured, to have a grip of the clutch system. It consists of,

Driving member,

- It has flywheel

- The flywheel is mounted on the crankshaft.

- There are few other components, pressure plate, spring & lever.

- A cover is associated with all these members,

- The cover is bolted to the flywheel.

- If the flywheel rotates, the cover will rotate.

- If the cover rotates, all the pressure plate, spring, etc. also will be rotated.

Driven Member

- It has a plate or disc, which is known as a clutch plate.

- There are splines on the clutch shaft.

- The Clutch can easily slide on the shaft.

- It has frictional surfaces.

Operating member

- Pedal which is pressed or release to engage or disengage.

How does a clutch work – Working Principle

Principle of Clutch: Take two-cylinder and keep them in contact. Now, if you rotate one cylinder, you will see another cylinder that will rotate at the same speed. Keep it in mind that both the surface will be frictional surface and pressure should be applied to avoid slip.

Explanation of Working Principle: Frictional surfaces or friction force and application of pressure help to unite both the cylinder or shafts and rotate at the same speed.

In automobile,

- Flywheel – a driving member of a clutch &

- Pressure plate – mounted is the driven member.

The flywheel is mounted on the engine crankshaft and it gets the same speed of the engine and the pressure plate is mounted on the transmission shaft are gets the same speed when engaged. It can be controlled with gear arrangement and can be disengage whenever required.

Sometimes a different kind of plates, basically friction plates are kept between these two members. The plates are known as pressure plates. This entire assembly is called a clutch. Hence, the following factors are the main parameters for clutch:

- Surface area: Frictional force between two surfaces depends on the surface area,

- Pressure: Application of pressure is another important parameter

- Frictional Force: Different materials provide different frictional forces, hence, it depends on type of materials.

Function of clutch

The main function of an Automobile Clutch is to Engage & Disengage.

Clutch Engagement

- In this case, the rotary motion of the engine is transmitted to the wheel.

- The clutch transmits engine power to the machines based on the requirements.

- In an ideal condition, there is no slipping between two components.

- The clutch slips momentarily and provide very smooth engagement

- Clutch lessens the shock on gears, shaft, and other parts of an automobile.

- It allows the engine to take the load without any jerks

Clutch Disengagement

- Controlling the clutch, vehicles are controlled.

- The vehicle can be stopped easily by disengaging the clutch.

- The engine will run without any impact or any transmission.

- In disengage, the clutch permits the driver to shift transmission different gears based on requirements.

- Gear shifting easy, without noise or damage

Types of clutch

There are various types of clutches used in the industry based on the applications. The selection of the right kinds of clutches for a specific industry totally depends on the beginning. Improper selection and application will incur less efficiency, hence, proper selection is a must to get maximum efficiency.

The working principle is different for clutches and each type has some advantages and disadvantages. The different types of the clutch are

- Friction Type Clutch

- Single Plate Type Clutch

- Multi-Plate Type Clutch

- Cone Type Clutch

- Centrifugal Type Clutch

- Semi-centrifugal Type Clutch

- Diaphragm Type Clutch

- Dog and Spline Type Clutch

- Electromagnetic Type Clutch

- Vacuum Type Clutches

- Hydraulic Type clutch

- Flywheel Type Clutch

Let’s discuss all types of clutches in detail.

Friction clutch

Description: Friction clutches are widely used in cars. This clutch is operated through a mechanical or hydraulic cable and consists

- a clutch plate,

- a pressure plate, and

- a release bearing.

These are further classified into two types,

- Single-Plate Clutch

- Multi-Plate Clutch

Single Plate Clutch

Single plate clutch means as the name implies, has only single clutch plate. It is widely used mainly in lightweight modern vehicles. It transmits the torque from an engine to the transmission input shaft.

Components: The components of the single plate clutch,

- flywheel,

- friction plate,

- clutch plate,

- pressure plate,

- clutch spring

- bearings,

- nut-bolts etc.

Advantages of Single Plate Clutch: There are few advantages of the single-plate clutch,

- It produces less heat

- No coolant is required for cooling

- Quick response

- Very smooth engagement & disengagement

- Operation is smooth

- The loss of power is very less due to low torque

- Very easy to change the gears

- Excellent load withstanding capacity

- It helps to safeguard other rotating parts.

Disadvantages of Single Plate Clutch shall be as follows:

- Size is big compared to other types.

- It is a dry type clutch, no cooling medium & high maintenance.

- Lubrication required.

- It is used only for low torque applications.

Applications

- Cars,

- Buses,

- Trucks, etc.

Multiplate Clutch

Multiple clutches are widely used in the industry. There are multiple plates and due to it, this clutch is known as a multi-plate clutch.

It mainly transmits the power from the driver shaft (engine shaft) to the driven shaft (transmission) shaft to produce high torque. Friction takes place between these two and high torque is developed.

It is used in F1 level racing cars, racing motorcycles, in many diesel locomotives, etc., in the case of high torque requirements. It is also used in many electronically controlled all-wheel drive systems now.

Multiple plate clutch is further divided into two categories,

- wet clutch and

- dry clutch.

A wet clutch is operated within the cooling lubricating fluid and gives longer life with smoother performance. Wet clutches tend to lose some energy to the liquid. However, due to multiple numbers of discs, it can compensate the frictional losses and eliminate slippage.

The Hele-Shaw is one type of wet clutch which works on viscous effects, other than on friction. A dry clutch, as the name implies, is operated without oil.

The advantages of the Multi-Plate clutch,

- torque is quite high due to multiple plates, as well as the more frictional area available.

- Compact and small in size, the application is in more area

- Used in racing cars etc.

- It has more frictional surfaces.

- The transmission of torque depends on the area of frictional surfaces.

- A multi-plate clutch produces more torque than a single-plate clutch.

- Acceleration is better.

Disadvantages of Multi-Plate Clutch

- The weight is heavy so it is not suitable for all-time use.

- The cost of the multi-plate clutch is very expensive.

- More friction, additional cooling arrangement required, incurs more maintenance.

Applications,

- High powered car.

- Motorbikes etc.

Working Principle of Friction Clutch

In the friction clutch, Single plate and multiple plates, friction is created between the engine shaft and the transmission shaft to provide the force required to move the vehicle. The working principle of friction clutch shall be, as follows:

- Firstly, driver needs to press the clutch paddle

- Spring will be compressed, due to this pressure,

- Pressure plate move backside

- Clutch becomes disengaged

- The shifting of the gears will be very

- It will rotate the flywheel until the engine shaft does not stop rotation.

- When the clutch is engaged, the friction plate will be sandwiched between the engine flywheel and a pressure plate

- There is a pressure between the pressure plate and flywheel

- If the pressure is sufficient, the friction plate will not be slipped and the vehicle performs well.

- If the pressure is not sufficient, the friction plate will be slipped and the vehicle will not perform properly.

Cone Clutch

In the cone clutch, there are two mating members of cone-shaped, one is a male member and another is a female member. When these two members are engaged, the frictional force is generated and transmission happens. The main components of cone clutch are,

- Male cone or internal or inner cone

- Female cone or external or outer cone

- Pedal

- Shaft

- Bearing

- Friction material

- Spring

- Splines

- Clutch Shaft

- Clutch control

- Friction Lining

Working principle: In the cone clutch, engagement & disengagement of the male cone and female cone member has happened.

- The female cone is mounted on the engine crankshaft

- The male cone is mounted on a spline clutch shaft

- Male cone easily slides on spline shaft

- Both the cones have conical shaped frictional surface

- Spring brings the male cone back after using clutch control

- Clutch control separates both the cones by pressing the paddle

- It uses these surfaces to transmit the torque.

- High torque is transferred since both the cones are fastened compactly with the larger surface area

Advantages of Cone Clutch

There are few advantages of Cone Clutch

- Higher torque generated

- Noise level is less with respect to plate clutch

- Low wear & tear in comparison with displacement clutch

- Energy efficient

- The normal force acting on the frictional contact surface is greater than the axial force.

- A very less axial force is required to engage the clutch

Disadvantages of Cone Clutch

Although there are some disadvantages of cone clutch, and here are those:

- Inefficient sometimes to disengage the clutch.

- If the cone angle is less than 20°, then the male cone tends to couple with the female cone makes it difficult to disengage.

- Small wear can make the large axial movement of the inner cone

- This leads to high maintenance.

Application

- Automobile industries

Centrifugal Clutch

A centrifugal clutch, as the name suggests, uses centrifugal force for operation. By using this type of clutch, the speed of the driven shaft can be controlled.

- It is operated based on the speed of an engine.

- No clutch paddle is required.

- The speed of the driver can be adjusted without changing the gear.

Components

- hub,

- drum

- flyweights (clutch shoes),

- springs,

- friction linings and

- spider or guide

- sliding shoe

- housing

Working Principle of Centrifugal Clutch: The centrifugal clutch has a weight, called flyweight, is pivoted in a specific location.

- The engine creates a centrifugal force by the revolutions on the crankshaft

- This force is transmitted to the flyweights

- The shaft of the clutch rotates at the same speed as the crankshaft

- The shoes are forced to rotate by the hub

- This process is going on unless shoes come into contact with the drum.

- In this way, torque is transmitted from the flyweights to the drum

- And drive will be then connected.

Advantages of Centrifugal Clutch

- This clutch is engaged and disengaged automatically.

- Smooth operation

- No shock waves

- Low cost

- Less maintenance

- Loss due to wear and tear is very less

- Easy to control the speed

- Highly efficient

- No separate control mechanism is required.

Disadvantages of Centrifugal Clutch

- Power loss due to friction

- Power loss due to slippage at a lower speed

- It is not suitable for high torque application

- High load condition, shoe slips.

- In the case of the high-speed engine, centrifugal clutches are not suitable.

- The maximum speed depends on the size of the clutch.

- At full power, the shoe gets heated

Applications

- Pumps

- Generators etc.

Semi-Centrifugal Clutch

We have already learned a centrifugal clutch. Now, if spring forced is used along with centrifugal force to engage the clutch, then it is called a semi centrifugal clutch. It consists

- Flywheel,

- Clutch plate,

- Weights with levers

- Friction lining,

- Clutch springs

- Pressure plate,

Working Principle of Semi-Centrifugal Clutch: In this type of clutch, levers and clutch springs fix upon the pressure plate equally. When levers or springs are fixed, power transmission happens. There are two options,

- At low engine speed: Spring fix itself to the clutch plate & transmit the power,

- At normal engine speed: Here, also, same as low speed. Spring is fixed.

- In this case, no pressure is exerted on the clutch plate from the levers.

- At normal speed, there is no pressure on the pressure plate and it remains engaged.

- At a high engine speed: weights fly off and due to this, levers give pressure on the pressure plate and the clutch is engaged.

- It helps to transmit high torque.

- In this case, springs are not required to be stiffer to keep the clutch engaged.

- Weighted levers with centrifugal force help to select the less stiff springs.

- When the speed of the engine decreases, the centrifugal force of weight reduces and it falls.

- It loses contact and no pressure force exerted on the clutch plate.

- But spring force exerted on the plate and clutch got engaged.

Advantages of Semi-Centrifugal Clutch

- The stiffness of the spring of this clutch is less & it operates at low speed only.

- Easy operation

- Shifting of the gear is very smooth & no stain in operation.

Disadvantages of Semi-Centrifugal Clutch

- Springs transmit the torque only at a lower speed.

- Only at high speed, centrifugal forces work to transmit the torque.

Application

- High powered engines

- Racing car etc.

Diaphragm Clutch

We have seen, coil or helical springs are used in the clutches. But in the case, spring is diaphragm type and that is why this clutch is known as a diaphragm clutch.

- Clutch has not required any levers

- The diaphragm spring acts like a series of levers

- Diaphragm springs don’t have any constant rate characteristics like coil or helical springs

- The diaphragm spring exerts pressures unless it becomes flat.

This type of clutch generates pressure on the pressure plate to engage the clutch. The diaphragm clutch consists of

- Flywheel

- Pressure plate

- Diaphragm spring

- Fulcrum ring,

- Release bearing

Working Principle of Diaphragm Clutch: In a diaphragm clutch, the diaphragm is used as a spring. It is a thin sheet of metal. When pressure is applied on the diaphragm, it yields and when pressure is removed, the diaphragm will come in the original shape.

- Friction lining consists of the flywheel.

- The flywheel is connected to this clutch.

- The Clutch is having a diaphragm spring.

- This spring is supported on a fulcrum.

- Spring and fulcrum act as a simple lever system.

- Behind the pressure plate, the clutch plate is placed.

- The pressure plate is in a radial position with respect to the cover and moves axially.

- Engine power is transferred to the flywheel from the crankshaft.

- When the clutch pedal is pressed.

- The spring load is relieved

- The Clutch is disconnected.

Advantages of Diaphragm Clutch

- It requires very less effort when the clutch needs to be disengaged.

- Less moving parts

- Low maintenance

- No noise

- Springs act as livers, hence, no additional release lever is required.

- Compact design.

- Small in size comparatively.

Disadvantages of Diaphragm Clutch

- Size is more, to get the coefficient of friction.

- Spring may become stiff after a certain extent.

- Difficult to use in heavy vehicles

Application

- Cars

- Light vehicles, etc.

Dog Clutch

Description: In this type of clutch, two parts of the clutch are engaged or disengaged. These two parts may be shafts or maybe shaft and gear.

Working Philosophy

- One part of the dog clutch is having external teeth (shaft or gear – male part)

- Another part (shaft – female part) is having internal teeth.

- When both this male and female part engaged

- Rotate at the same speed.

- Due to these teeth, no slippage.

- When the male part is taken out from the female part, the clutch got disengaged.

Advantages of Dog Clutch

- Attachment with teeth, hence, no slippage between two parts.

- Produce high toque.

- Very efficient for power transmission.

Disadvantages of Dog Clutch

- It is not possible to engage the clutch at high speed

- Relative motion is required, during engagement & disengagement.

Application

- Manual cars

- Marine propeller drives, etc.

Spline Clutch

In this kind of clutch, there will also be two mating parts. There will be spline on the driven shaft and grooves will be in the driving shaft.

Working Philosophy

- The driven shaft is having a spline

- The driveshaft is having grooves

- During the engagement, spline and grooves are attached.

- Both are rotating at the same speed.

- No slippage as the same as a dog clutch.

- When the spline is taken out from grooves, the clutch got disengaged.

Advantages of Spline Clutch

- Clutches engaged very strongly, and no chance of slippage.

- High torque is produced like a dog clutch.

Disadvantages of Spline Clutch

- Difficult to engage at high speed.

- Additional relative motion is required.

Application

- Manual cars

Electromagnetic Clutch

Electromagnetic clutches or sometimes called electromechanical clutches, or EM clutch works electrically but remember transmission of torque is by mechanical means. An EM clutch consists of,

- Metal housing or stator

- An electromagnetic coil

- A rotor

- Winding

- An armature

- Hub

- Friction plate

- Battery or dynamo

- Clutch switch

- Wire

Working Principle of EM Clutch

The working principle shall be as follows,

- Battery or dynamo is used to supply DC power.

- This power is supplied to the winding.

- An electromagnetic field is produced in the coil.

- The pressure plate is attracted to the stator.

- The Clutch is engaged.

- Torque is transmitted from the rotor to the armature.

- If the power supply is stopped, the clutch will be disengaged.

- The Clutch is disengaged once required by changing the gear.

Advantages of Electromagnetic Clutch:

- Easy operation.

- Widely used in the electrical system.

- The remote application is suitable.

- No linkage is required.

Disadvantages of Electromagnetic Clutch:

- Capital cost is high.

- Limitation on high temperature.

Clutch Plate Material

There are various materials used to construct a clutch. Clutch plates are the main component in the clutch. Earlier asbestos is widely used, however, in the recent era, there are different kinds of materials used for clutches. Ceramic materials, organic, semi organics, etc. are widely used based on the applications.

Organic materials

- Widely used materials.

- Phenolic resins, compounded rubber, or metallic powders may be used.

- Durability and longevity are very good.

- Heavy-duty organic materials are also available now a day, which can withstand very high temperature.

Ceramic Materials:

- This is made in a combination with copper, bronze, silicon, and graphite etc.

- Widely used in trucks, racing cars, etc.

- It can withstand large friction and heat.

Semi-Metallic Materials:

- It is used the combination of copper, steel & iron.

- Highly durable

- High-speed application.

Feramic Materials

- Heavy-duty application.

- High grade of ceramic discs.

- Combination of silicon, graphite & steel.

What are Common Problems

There are a few common problems associated with clutches:

- Wear is the main problem that is the clutch. Constant friction between two friction materials will cause to wear out.

- While driving, if the clutch is not released properly, it will create a problem on grinding, or shifting the gears.

- The stretched clutch cable can be broken if there is a problem of tension to push and pull.

- If there is a leakage in the cylinder to create necessary pressure.

- If there is a problem of air in the hydraulic line which builds the pressure.

- The wrong amount of force applied in the pedal will transmit an imbalanced force.

- Mismatched clutch components

- Sticking or binding can happen if there is a problem in the linkage, cabling, pivot, etc.

- Worn seals in the hydraulic system can make a hard clutch.

- Worn throw-out bearing or clutch release bearing may create problems and a rumbling sound comes when the clutch engages.

How to check clutch health?

It is required to check the health of the clutch often since it is having a vital role in vehicle performance as well as our safety. This health can be checked by us only. Check out the below tables:

| Sl. No | Description | Noise | Remarks |

| 1 | Start your car, keep your hand break up & keep it in neutral mode. Now, without pushing the clutch, listen for a growling noise. | No noise coming | No issue on clutch |

| Noise coming | It is a problem associated with transmission. | ||

| 2 | In the same neutral conditions, start to push the clutch | No abnormal noise | No problem in clutch |

| 3 | Chirping noise | throw-out bearing | |

| 4 | Push the clutch up to maximum | No different noise | No problem here |

| Squealing noise | pilot bearing or bushing problem |

Clutch Slipping Symptoms

The clutch performance will diminish over time, and clutch slippage should be relatively apparent to a competent, clued-up driver. There are a number of signs you can look out for that would push you towards a diagnosis.

- The squeaking sound may come.

- The problem in changing gears

- The clutch pedal sticks vibrate or feel spongey

- Acceleration is a struggle, experience momentary losses

- A burning smell under the hood, this may also mean bad wiring or an oil leak

- Clutch disengages very quickly

- Revs are very high

- Clutch pedal height

Conclusion

We have learned the basics of the clutch, along with different types of clutch and descriptions, working principles, advantages, disadvantages.